展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

VICTOR TAICHUNG MACHINERY WORKS CO., LTD.

製品の説明 :

.One piece 30˚ slant bed with large swing diameter

.10" Power chuck / 3500 rpm (A260)

. Z-axis travel 750 mm

.High thrust force by small pitch ballscrew

.High rapid feed 24 m/min (Z-axis)

.Shortened belt driven spindle

.Digital tailstock

.8” chuck for subspindle (opt.)

REN AN INFORMATION TECHNOLOGY CO., LTD.

製品の説明 :

Guided-steps CAD/CAM with Machining Simulation including tool path verification and machining time.

Excellent tool for learning CAD/CAM and verifying with simulation.

HC FENG CO., LTD.

製品の説明 :

FOODIE (Chip/Sludge Removal Machine) works for :

Filtration/Removal of excess components

Chip/Sludge Removal

Fine Chip Removal

No downtime

No consumables

Backwater automatically & simultaneously

Air pressure drive w/o a plug

Vertically fast filter drying up to 90% efficiency

Precision filters effective up 20% for super filtration micro-fines

Easy to move

Filter accuracy can be adjusted

Extend cutting fluid life

MING YANG MACHINERY CO., LTD.

製品の説明 :

This multi-tasking turning center is an advanced machine designed to process precision complex parts in one setup.

Power & Versatility: It has Double Spindles, a VDI/BMT 12 station Turret and a 2nd Y-Axis for back machining with 14 tools for a total capacity of up to 38 tools. This solution with superimposed cutting is a powerful combination of precision and two Y-axes for machining of complex workpieces with extremely fast cycle times.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: Gang Tools Slide: 14 Tools, 3 Cross Live Tools, 3 Face Live Tools, 3 OD & 5 ID Tools.

CHIAH CHYUN MACHINERY CO., LTD.

製品の説明 :

SY2-42 Swiss-type CNC Lathe

■ SY2-42E has Ø42mm maximum bar feeding dia. and provide the option to go with or without a guide bush to achieve optimum machining condition.

■ Main spindle tool system can install 6 radial live tools, 3 axial live tools, 6 O.D. tools, 5 I.D. tools.

■ Sub Spindle tool system can install 8 ER-20 live tools, combines with the Y2 linear axis and C2 rotating axis to perform the more complex turning and milling process.

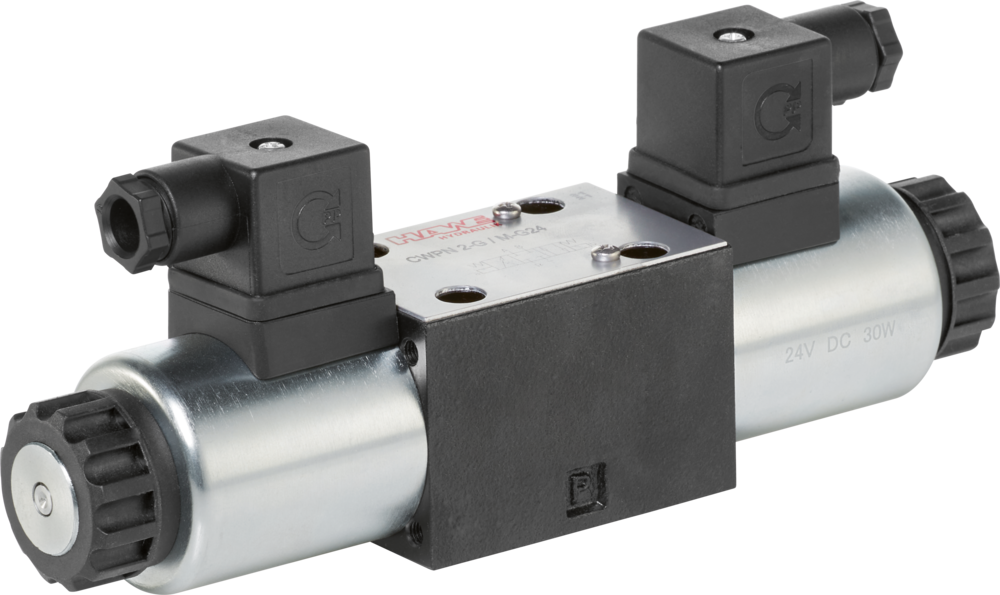

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

製品の説明 :

Directional spool valves are a type of directional valve. They control the direction of

movement and the velocity of single and double-acting hydraulic consumers.

The directional spool valve type CWPN is a 4/3- or 4/2-way directional valve with standard connection pattern NG 6 (CETOP 03). It is directly actuated and a binary

valve.

The directional spool valve type CWPN can be flexibly combined with the common HAWE valve banks and compact hydraulic power packs. It can also be mounted on customer-specific manifolds or sub-plates.

Features and benefits

■ Universally usable thanks to standard connection pattern NG 6 (CETOP 3) according to ISO 4401-03 or DIN 24 340-A6

■ Modular system with various circuit symbols and actuation variants

■ Optionally also available with additional valves in port P

Intended applications

■ Machine tools

■ Wind turbines

■ Solar power plants

■ Industrial hydraulics

CHIAH CHYUN MACHINERY CO., LTD.

製品の説明 :

The CT1-76YM is designed with a combination of double spindle and single turret.

■ ∅76mm enlarged spindle bore is ideal for turning large workpieces. ■ 16-positions power turret with Y-axis, it can complete machining on parts in the main or sub spindle. In addition, tools can be placed facing either the main or sub spindle.

TAIWAN MACHINE TOOL CO., LTD.

製品の説明 :

Strong casting and the perfect boxway stucture provides excellent cutting capacity for TTB-20MW Series. Sub-spinfle with milling function and Y-axis can satisfy customers' miltiple needs.

-The one cast base incorporates FEM analysis to achieve its optimal ribbing and structure to further enhance machine rigidity and stability.

-The 30 degree slant bed design has low center of gravity for easier swarf management and better erogonomic design. The TTB-20MW Series also offer optional rear type chip conveyor.

-To make sure the usage life of Y-axis ballscrew will get longer, there are three bearing on Y-axis ballscrew to enhance the support for pressure from top.

-The TTB-20MW Series can achieve maximum 20m/min for X axis and 25m/min for X axis. And the servo motors adopt absolute encoders for faster and more reliable positioning.

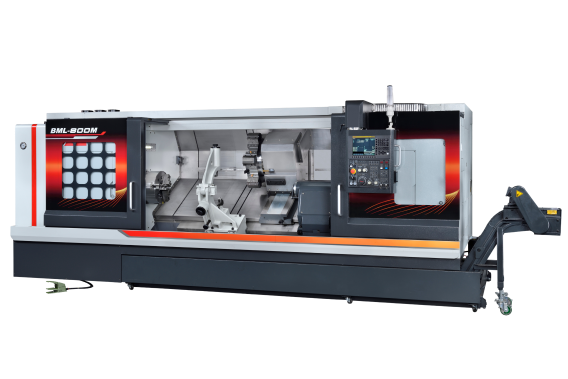

YIDA PRECISION MACHINERY CO., LTD.

製品の説明 :

The (B)ML-800 series is a highly customizable turning center with various options for spindle, gearbox, base, tailstock, turret and multiple selectable feed speeds. It can efficiently handle the most demanding machining requirements.

1. The modular structure design of the base has high strength and rigidity. It is molded as a single unit, effectively absorbing the vibrations generated by the machining and providing the stability and precision required for heavy cutting operations, without any distortion or deformation.

2. The optimal modular design spindle features high speed and power, and can be paired with a high-torque output gearbox design, offering a variety of processing options to meet different machining needs.

3. The robust toll turret design allows for quick and reliable tool changes, ensuring high efficiency and precision. It caters to the characteristics of various cutting processes, effectively enhancing machining capabilities.

3. The high-strength design of the transmission structure ensures precise positioning and greatly enhances machining efficiency and stability.

4. Ergonomically designed interface makes operation easy and maintenance convenient. Sheet metal design incorporates comprehensive safety considerations.

MING YANG MACHINERY CO., LTD.

製品の説明 :

This heavy duty multi-tasking turning center is an advanced and economical solution designed to process precision complex parts with fast cycle times.

Power & Versatility: It has Double Spindles, a BMT 12 station turret and 4 gang tools for economical machining. Coupled with superimposed cutting it’s a powerful solution for precision complex workpieces with extremely fast cycle times.

Front Machining: BMT 45, 12 Stations, Up to 24 Tools, 7.5/11 kW Spindle Power, 55 mm Through Hole

Back Machining: GT42: 4 x 20 mm ID Tools, GT52: 4 x 16 mm ID Tools, Or 3x 20 mm ID Tools, Or 3x 25 mm ID Tools