展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

FUTECH PRECISION CO.,LTD.

製品の説明 :

FUL series CNC Lathe is to enhance high speed and high accuracy. 45 degree slant bed construction features high rigidity and high stability.

X、Z axis are mounted with ball type linear guide ways or box guide ways. Axis movement is directly driven by a servo motor , allowing the high rapid traverse rates on X、Z axis.

ANNN YANG MACHINERY CO., LTD.

製品の説明 :

CNC Lathe with big spindle bore 255mm, double chucks, for oil pipe

MONGTEC PRECISION INC.

製品の説明 :

BODY

Re-designed main body to improve rigidity and reduce vibration. Specially treated corrosion resistant steel body.

Bearings

Angular contact preloaded ball bearings of precision class P4 / ABEC 9.

Bevel Gears

Gleason computer based calculations for the Gleason cut spiral bevel drive gears with ground teeth in order to guarantee a bigger torque.

Torque and Speed

With Speeder 1:4:32,000 Rpm

(Standard 1:1:6000~12000Rpm)

Max Torque:160Nm

Internal Coolant

Max Pressure:70-100 bar

LEADWELL CNC MACHINES MFG., CORP.

製品の説明 :

LTC-35LY is a high-performance CNC lathe, suitable for machining various complex parts, especially parts for the automotive industry. It has the following advantages:

The bed structure is very rigid and able to withstand large cutting forces. The spindle and servo motor are high-speed and high-precision, able to quickly and accurately complete the cutting and drilling actions. The Y-axis function allows it to add another moving direction perpendicular to the spindle, in addition to the X-axis and Z-axis, which enables it to achieve more machining angles and shapes, improving the

flexibility and accuracy of machining. The CNC system supports various CNC programs, making it easy for users to design and operate according to different workpieces, reducing errors and waste. It has excellent performance and can improve the quality and efficiency of products, reduce costs and time, and bring more value and competitiveness to users.

Max. swing: 800mm

Max. turning diameter: 430mm

Max. turning length: 1530mm

Bar capacity: 115mm

X-axis travel: 215+25mm

Z-axis travel: 1600mm

Y-axis travel: +100/-80mm

Spindle speed: 2000rpm

Spindle nose: A2-11

Chuck size: 15"

Number of tool stations: 12T

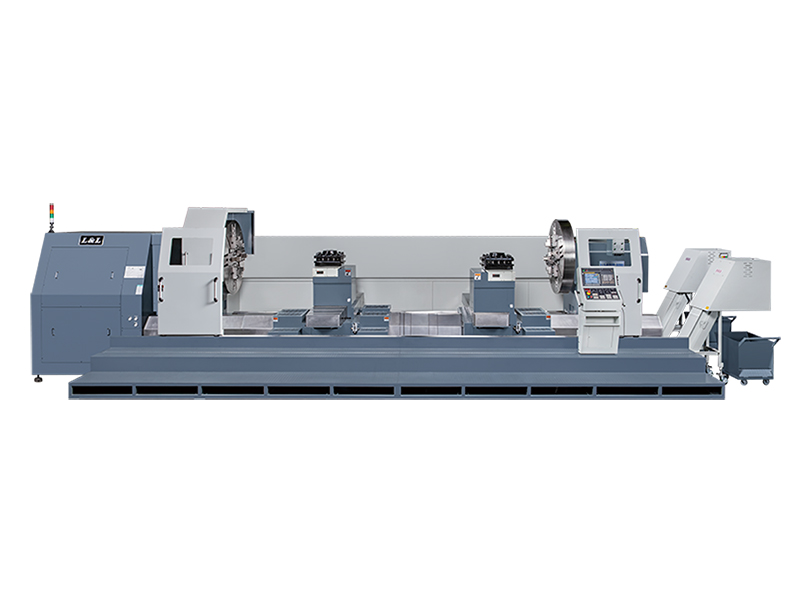

L & L MACHINERY INDUSTRY CO., LTD.

製品の説明 :

Smart heavy-duty multi-axis composite cutting machine, LLS-M, for the target industry market (oil industry, aerospace industry, steel industry and rubber and rubber industry), achieved ALL Processes In One Machine to reduce the clamping and shortening process, with precision and life management The intelligent machine, constructing the machine information management platform and man-machine management interface, integrating the computer numerical controller, the smart set-top box and the cloud product life cycle database, providing relevant data and data through artificial intelligence calculation analysis and application, reaching the machine Accuracy and life and performance improvement, and applied to the virtual reality pre-sales service system, the use of the real-life expansion after-sales service system to build a smart mechanical value service chain.

SGCAM TECHNOLOGY CO., LTD.

製品の説明 :

主功能介紹:<br />

全中文畫面,易學、易懂、易用,為加工業最適合的加工軟體,操作軟體完全不用背指令。<br />

可由AutoCAD製圖畫出工件外形,再匯入DXF、IGS圖檔,轉換為CNC程式碼。<br />

不必畫3D圖形,一條輪廓線和一條路徑線一般2D圖即可輕鬆轉出車銑的加工程式。<br />

快速C軸填充式的輸入方式 ,很簡單的方式就能轉出C軸加工程式。<br />

參數式的C軸工法操作條件更改G碼自動跟著改變。<br />

製作程式時車銑工法可依加工順序任意作排序調整。<br />

3D實體切削模擬預覽,可避免干涉及過切事件發生。<br />

主軸和副主軸的獨動或同動會自動等待(指定機型) 。<br />

同一個程式中可同時指定不同的切削計算方式有走刀式、走心式、櫛式。<br />

車銑的刀具庫參數可依實際機台型號的刀具位置做個別指定。<br />

可在端面、圓弧面、橢圓面上做刻字。<br />

支援單筆劃字型刻字。<br />

系統支援:<br />

支援廠牌有Citizen 、Star、Miyano、Tsugami、洽群、縉錩、利高、精機、瀧澤、程泰、寶麗金…<br />

支援側銑側鑽等循環加工指令G87、G88、G184<br />

支援極座標G12.1 、G13.1、 G112 、G113<br />

支援圓筒補間G07.1、G107

MING YANG MACHINERY CO., LTD.

製品の説明 :

The model MTY 51/65 is equipped with a dual spindle double turret and double Y axes. The machine is combined with FANUC 31i PLUS for simultaneous control on triple tool systems. The machining support two turrets for one spindle and one turret for two spindles at the same time. In other words, each process will collaborate with three tools. Mostly, the machine improves 50% efficiency.

REN AN INFORMATION TECHNOLOGY CO., LTD.

製品の説明 :

Guided-steps CAD/CAM with Machining Simulation including tool path verification and machining time.

Excellent tool for learning CAD/CAM and verifying with simulation.

CENTURY TRADING CORPORATION

製品の説明 :

是大批量加工最佳的自動化系統方案,並全方位提供技術支持

瀧澤平行雙主軸CNC車床(TT),主軸面向正面,平行配置兩個主軸。可進行左右獨立的加工控制,CM規格能自由進行車削和銑削加工,實現了工序的極大集約化。瀧澤原裝龍門上料機可進行前後同步加工,左右同步加工和多個工序的全自動加工等多種自動化系統,完全滿足高生產效率的要求。

CENTURY TRADING CORPORATION

製品の説明 :

• 在以第1及第2主軸進行加工中,以第3及第4主軸進行裝載/卸載動作業,加工/拆裝同時進行,加載時間實際上爲零!

• 4個夾頭,4個操作(OP1、OP2、反轉、工件拆裝)集中到1台機器上,同時進行拆裝。經常出現切屑的高運轉率車床, 大幅縮短循環時間,提高生產效率!

• 由於裝卸用主軸在分隔門外, 更方便於更換夾頭及手動拆裝的機械設計。

• 機械手臂可在機上安裝,在不佔空間的情況下,可以實現自動化。把機械手臂放在滑軌上,就能達到龍門裝載機水平。

JARNG YEONG ENTERPRISE CO., LTD.

製品の説明 :

1. High rigidity body structure, machine base casting is integrally formed and high rigidity linear guide way, providing stabler, faster and higher precision.

2. Built-in main spindle is with C-axis function, high speed, big power, high precision and low vibration which can make surface of workpiece smoother.

3. Optional:Synchronous rotary guide bushing device, it's suitable for processing long workpiece which can reduce cycle processing time and improve production efficiency.

4. Sub-spindle is with C-axis function, it can work with live tooling for end side drilling, tapping and milling.

5. It can depend on different demand of machining to with or without Synchronous rotary guide bushing device.

6. Axes:Z1/X1/Y/C1/Z2/X2/C2 + 3 sets of live tooling devices (A/B1/B2)

7. Max. 23 tools, can do machining on front side and back side at the same time which can save time for processing.

8. With guide bush type travel is 180mm, min. offal is 150mm. Without guide bush type travel is 310mm, min. offal is 50mm.