展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

LEADWELL CNC MACHINES MFG., CORP.

製品の説明 :

The 5 axes simultaneous processing, can reduce the times of workpiece unloading and the requirement of the jigs, shorten the processing time and improve performance. C-axis table using the DD motor provides high torque and rigidity and can solve the traditional worm gear backlash and worn problems. High torque and efficiency of the spindle with a complete high-rigidity structure applied results in roughing to finishing can be completed on the same machine, suitable for machining hard materials and non-ferrous materials processing.

X-axis travel: 1300mm

Y-axis travel: 610mm

Z-axis travel: 610/750mm

Table size: 1480x610mm

Max. table load: 1600kg

Spindle speed: 12000rpm

C-axis speed: 800rpm

X/Y/Z-axis rapid traverse: 36/36/30 m/min

Tool storage capacity: 30T

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

製品の説明 :

Compact hydraulic power packs are a type of hydraulic power pack. They arecharacterised by a highly compact design, since the motor shaft of the electric drive also acts as the pump shaft. Compact hydraulic power packs are designed to supply hydraulic circuits with hydraulic fluid.

The compact hydraulic power pack type INKA consists of the tank, the integrated motor and the radial piston pump or gear pump directly attached to the motor

shaft. The directly mounted electronic communication box with integrated realtime operating system allows the operating state to be recorded and visualised. The

measured values of the integrated multi-sensor (including the motor speed) can be passed on to the higher-level machine controls via standardised interfaces and processed there.

The consistently modular design of the type INKA means that different usage volumes and delivery flows can be realised quickly and easily from the modular

system. Compatible, ready-for-connection, complete solutions can be assembled easily using a wide range of connection blocks and the valve banks that can be combined with them.

Features and benefits

■ Prepared for condition monitoring with integrated sensors and communication box

■ Optimum efficiency through under-oil motor cooling, direct power transmission,and sophisticated heat dissipation

■ Suitable for nominal operating modes S2 (short period operation) and S3 (periodic intermittent operation)

■ Resource-saving due to small oil filling volume

Intended applications

■ Machine tools and material testing

■ Hydraulic tools

■ Handling systems

■ Presses and processing machines

MANFORD MACHINERY CO., LTD.

製品の説明 :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

REN AN INFORMATION TECHNOLOGY CO., LTD.

製品の説明 :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.

KAO FONG MACHINERY CO., LTD.

製品の説明 :

5-axis synchronous machining of the KMU series can be used for multi-faceted processing of workpiece clamping positioning at one time or processing deep hole mold and inverted hook area.

Three-axis structure using box-type construction design, which can effectively improve the rigidity of the machine.

X / Y / Z axis with high rigidity roller type linear guideway, with high rigidity, fast moving, low wear and other characteristics, which can greatly enhance the processing dynamic precision and stability and effectively increase production efficiency.

FAIR FRIEND ENTERPRISE CO., LTD.

製品の説明 :

★Gantry type structure

- Designed with a gantry type structure, the Feeler U800-5AX 5-axis machining center has the feature of spacious machining space, allowing large workpiece to be loaded and unloaded with ease. It is also convenient for operator to check the current machining condition at any time.

★U-shaped construction of base and column

-The advanced U-Shape structure significantly increases structural rigidity and machining accuracy.

-X.Y.Z axis rapid traverse rate reach 48m/min.

- Suitable for equipping with a large diameter of rotary table.

★Three axes overlap and separated from two rotary axes

- This design avoids a distance between the machining point and the intersection point of two rotating axes.

- Easy to compensate for the errors of radius on rotating axes and movement on three linear axes to ensure the machine's stability and accuracy.

★Separated design for three axes moving area and machining area

- This design feature not only makes chip removal more convenient, but also enables better chip-prevention capability of the machine.

- The rotaary shaft speed is increased by 800 rpm, which makes the turntable have a high-speed turning function.

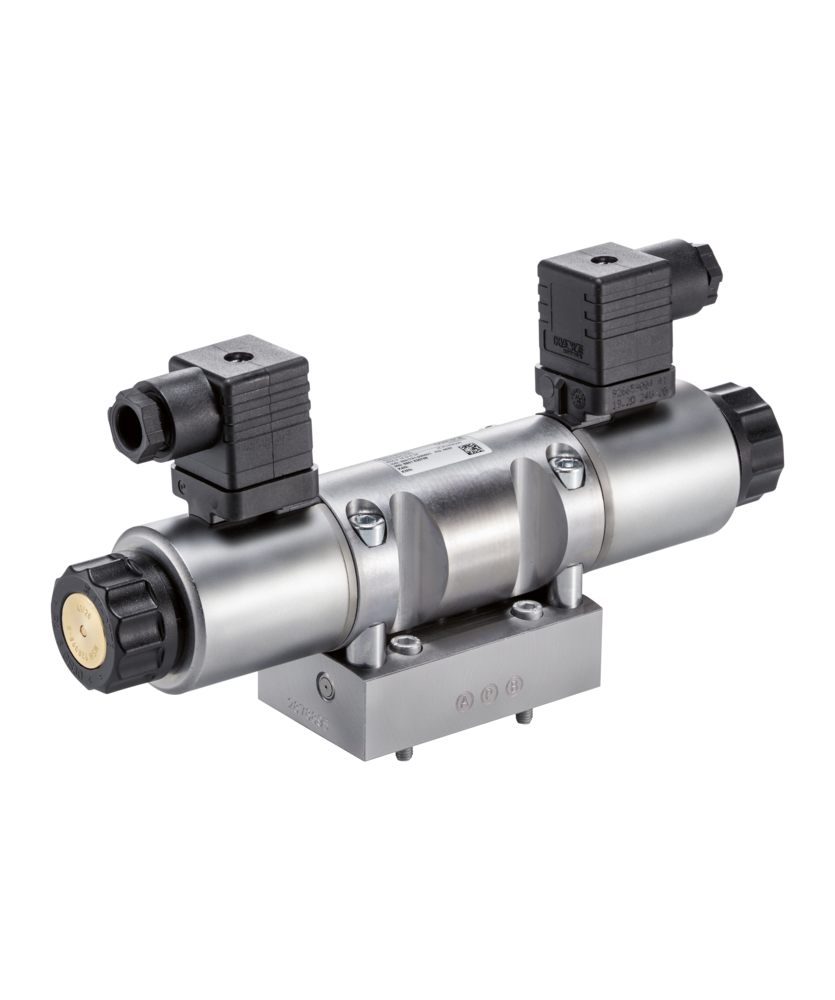

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

製品の説明 :

Directional seated valves are a type of directional valve. As cone valves they are tightly sealed, with zero leakage in the closed state.

The directional seated valve type ROLV is available as a 3/2, 4/2 or 4/3-way directional seated valve with different plug types. The patented assembly consists of two parts: a round basic valve with the valve inserts, and an adapter plate which can be designed for manifold mounting with nominal size NG 6 as the

standard connection pattern, or for direct pipe connection.

Additional elements such as a check valve, a restrictor (on the consumer side) and/ or restrictor check valves can be integrated, depending on the functional requirement and adapter plate. The type ROLV can be combined in the valve bank type BA with other types of valves.

Features and benefits

■ Dirt-resistant design with high switching reliability

■ Interchangeable solenoid for greater flexibility and easy servicing

Intended applications

■ Machine tools (cutting and non-cutting)

■ Clamping tools, punching tools, fixtures

■ Testing machinery

■ Wind turbines

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

製品の説明 :

■ The unique IDD spindle design provides power, speed, and stiffness required for the most adverse machining applications while providing long spindle life.

■ Ceramic bearings help to minimize heat and provide thermal stability improving overall machining accuracy.

■ High precision rotary encoders in the B and C

axes as a standard feature, allowing for the most demanding machining accuracies.

■ ø650 mm table provides stable machining performance with a wide machining area and trunnion support.

QUASER MACHINE TOOLS, INC.

製品の説明 :

Flexible Manufacturing System provides a solution for

massive production or high mix low volume. Simple installation

design helps users to increase productivity in a short time.

The intelligent Automatic Pallet Change Cell has a compact

footprint design with, 6 or 8 pallet options. APC can be field

retrofitted even if the machine is settled months or years ago.

Robotic Tool Magazine Cell is a perfect match for lights out machining.

It also has a small footprint to maximize the user’s facility space.

6 manual loading pockets reduce tooling loading time efficiently.

CAMPRO PRECISION MACHINERY CO., LTD.

製品の説明 :

Campro manufactures a family of Double Column Machining with size up to 5,200 x 3,100 mm travels. The machines offer the highest accuracies of any bridge mill on the market and can machine large parts efficiently with its rigid design. The extended Y-axis has full supported and constructed with a base/bed casting. The PV-XX16 (1,600 mm travels on Y-axis) is one-piece monoblock column structure that is bolted to the bed, delivers rigidity and stability. The PV-xx21 and PV-xx26 have wider door span and bigger machining range, the optional 1,000 mm Z-axis travel is best for attached head requested user.