展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

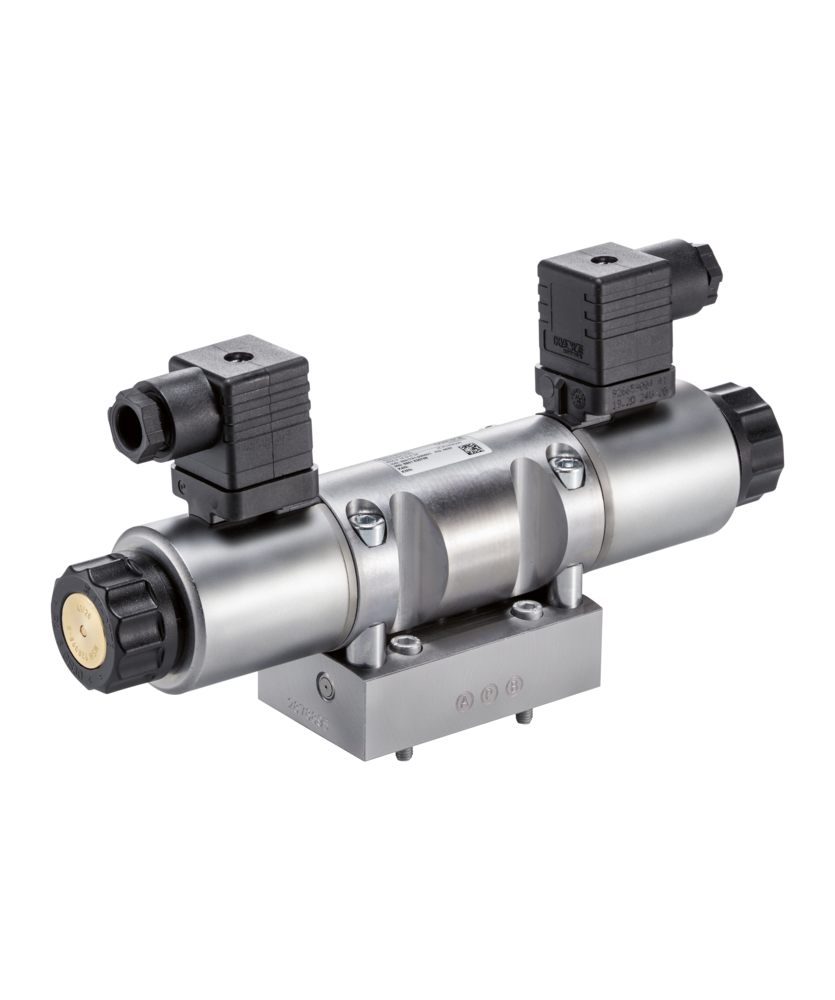

製品の説明 :

Directional seated valves are a type of directional valve. As cone valves they are tightly sealed, with zero leakage in the closed state.

The directional seated valve type ROLV is available as a 3/2, 4/2 or 4/3-way directional seated valve with different plug types. The patented assembly consists of two parts: a round basic valve with the valve inserts, and an adapter plate which can be designed for manifold mounting with nominal size NG 6 as the

standard connection pattern, or for direct pipe connection.

Additional elements such as a check valve, a restrictor (on the consumer side) and/ or restrictor check valves can be integrated, depending on the functional requirement and adapter plate. The type ROLV can be combined in the valve bank type BA with other types of valves.

Features and benefits

■ Dirt-resistant design with high switching reliability

■ Interchangeable solenoid for greater flexibility and easy servicing

Intended applications

■ Machine tools (cutting and non-cutting)

■ Clamping tools, punching tools, fixtures

■ Testing machinery

■ Wind turbines

YIDA PRECISION MACHINERY CO., LTD.

製品の説明 :

The MT-900 has a 5-axis milling head, two turrets, a tool magazine and twin spindles.

The design layout allows for maintaining a large work envelope for both lathe operations-turning and milling.

All six sides of a part can be machined without an operator having to manually resettle the workpiece, so nearly any parts can be machined in an automated manner.

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. High Speed, stability, and high precision provide a competitive edge in precision mold and die machining.

2. Precision cooling system with thermal compensation function to improve accuracy.

3. Environmental protection design reduces environmental pollution.

4. Could be equipped with automation/remote monitoring to improve production efficiency.

5. The machine's appearance combines fashion and technology while injecting the meaning of high speed, stability, and eco-friendly

LEADWELL CNC MACHINES MFG., CORP.

製品の説明 :

The 5 axes simultaneous processing, can reduce the times of workpiece unloading and the requirement of the jigs, shorten the processing time and improve performance. C-axis table using the DD motor provides high torque and rigidity and can solve the traditional worm gear backlash and worn problems. High torque and efficiency of the spindle with a complete high-rigidity structure applied results in roughing to finishing can be completed on the same machine, suitable for machining hard materials and non-ferrous materials processing.

X-axis travel: 1300mm

Y-axis travel: 610mm

Z-axis travel: 610/750mm

Table size: 1480x610mm

Max. table load: 1600kg

Spindle speed: 12000rpm

C-axis speed: 800rpm

X/Y/Z-axis rapid traverse: 36/36/30 m/min

Tool storage capacity: 30T

NUMEN MACHINERY CO., LTD.

製品の説明 :

* Double column structure and high rigidity design can

provide mold processing industry with high precision

and high efficiency of the performance.

* The superior cutting rigidity, more user-friendly

operation mode and machine stability can improve the

efficiency of operators.

KAO FONG MACHINERY CO., LTD.

製品の説明 :

KG series gantry five-sided machining center is able to choose to carry all kinds of automatic additional head (90゜angle milling head, universal head, extension head, speed-up extension head ... etc.) auto tool changer. Standard verticaland horizontal tool changer magazine tool with optional multi-head library for automatic head exchange. Angle head part has 5° division curved tooth with standard high precision, and are able to select 1/2.5°division or watering function at the center. KG5A series bridge crane five-axis machining center is mainly designed for the processing demand on medium and large weight workpieceparts, with world-class high-quality five-axis manufacturing technology to complete the five-axis processing, it synchronously completes vertical, horizontal and a variety of free angle of processings, which substantially increases the processing efficiency. Floor-type workbench with super load capacity, up to 2.5 tonsweight per square meter. Adopting HSK-A63 24,000 rpm high-speed spindle or the heavy cutting spindlewithHSK-A100 10,000 rpm high-torque output depends on different maching applications, which greatly improves the processing efficiency of large workpiece, and fully meets the processing needs of different industries.

EUMACH CO., LTD.

製品の説明 :

GVM-800U 專為高精度複雜多曲面銑削而設計,只需一次裝夾,甚至可以車削。從靜態剛性和動態質量的角度來看,每個關鍵部件的堅固框架都經過了很好的優化,以成為最高性能的天車式五軸加工中心。 雙Y軸驅動龍門型結構,絕對抑制了極高速(48m / min)加速/減速產生的振動。不僅可以提高生產前置時間,加工精度,還可以通過緊湊的設計優化工作環境,提高公司的整體管理水平。

直接驅動工作台由二個扭矩電機驅動,A和C軸各一個,最大速度50/100RPM,最大負載920/1200kg,旋轉角度A/C軸±125゚/ 360゚,達到新的高水平動態銑削和車削操作!

刀庫是由交流伺服電機驅動,以簡單,快速,無故障和極其平滑的刀具交換,標準32把刀及更多選擇。高速內藏式銑/車削電主轴18000~24000RPM可供選擇。搭配HEIDENHAIN TNC640,15”螢幕的五軸連動控制器,HEIDENHAIN高精度三軸光學尺,該加工中心用於飛機渦輪元件的加工及鋁製汽車輪圈高速表面處理提高了生產力。

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

製品の説明 :

Expertise, Innovation, Performance

S5A-4732HH, Special for Difficult-to-Cut Materials processing, Titanium Alloy processing.

Features:

High-Rigidity structure design. Mechanical-type Simultaneous Two-Axis rotary spindle. Warm and gear transmission for B and C axes. With self-made heavy-cutting two-stage gearbox design (Gear Ratio by 1:1.75 and 1:7). Maximum Torque: 1155 N-m.

Unique patented design of the Z-axis spindle rail structure - vibration restrain in machining. It can largely reduce the vibration in machining hard-to-cut material, enhance the machining efficiency, reduce the surface roughness, and prolong the tool’s life. (Model S5A-HH exclusive)

Fully Splash Guarding design. Super large and wide working door design. Fashionable aesthetic and ergonomic safety design.

Specific design of safety guardrail upon the cross column. Convenient for machine maintenance.

Height-adjustable manipulation control box. Suitable for people of different height.