展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

VISION WIDE TECH CO., LTD.

製品の説明 :

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively, and to extend tool lifetime and offer the best choice for composite angle machining. GSF Series had excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

•Continuous 2-axis head

•5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

•Built-in Spindle Direct-Driven on B&C axis, 12,000~24,000rpm spindle speed.

•Backlashless driving on B/C axis,Rotation Positioning accuracy ±5”.

•Low table height, closer operating zone, wider door width are convenient design for user.

•Chain type chip conveyor (standard) is able to remove iron chips efficiently.

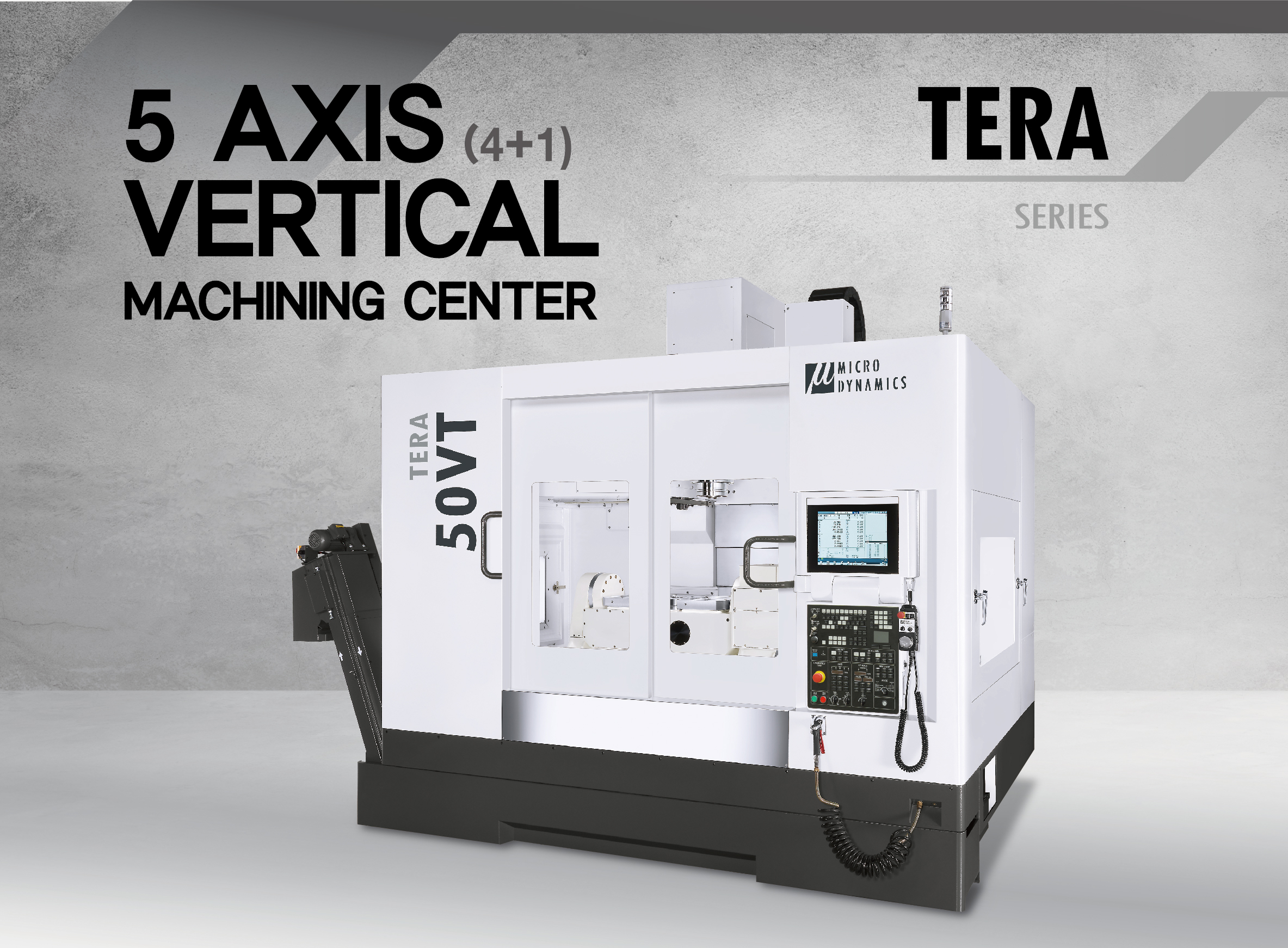

INNOSERV FA INC. TAIWAN BRANCH (BVI)

製品の説明 :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

HC FENG CO., LTD.

製品の説明 :

Oil Slick Treatment

Plug-In Free

No Consumables

Water Purification

Removes Odor

Optional Features

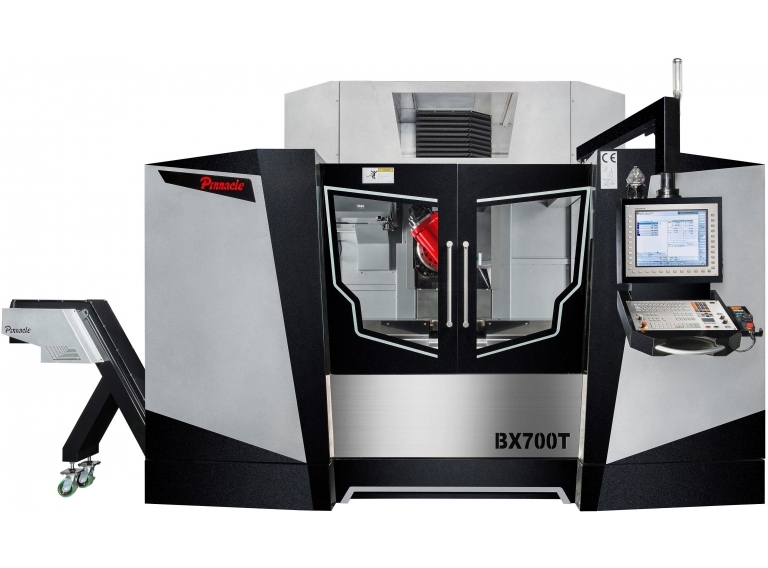

YING HAN TECHNOLOGY CO., LTD.

製品の説明 :

5-AXIS VERTICAL MACHING CENTER BELONGS LINEAR WAYS ON THREE AXES, X, Y, Z -AXIS TRAVEL: 800x600x550mm, MEEHANITE CAST IRON IS TEMPERED FOR STRESS RELIEF TO ENSURE STRUCTURAL STABILITY WITHOUT DEFORMATION. REINFORCED COLUMN BASE GREATLY INCREASES STRUCTURAL STRENGTH AND WILL EXHIBIT ULTRA-HIGH STABILITY DURING HIGH SPEED OPERATION. WITH THE EQUIPMENT OF CNC TILTING ROTARY TABLE, THE MACHINE IS ABLE TO PERFORM 5-AXIS MACHINING, IT CAN MACHINE COMPLEX, MULTI-SIDED PARTS IN A SINGLE SETUP, THEREBY REDUCING SETUP TIME WHILE INCREASING PART ACCURACY.

REN AN INFORMATION TECHNOLOGY CO., LTD.

製品の説明 :

1. Production progress control

2. Finish time estimate

3. Cutting Feedrate Verify monitoring

4. Machine alarm notification

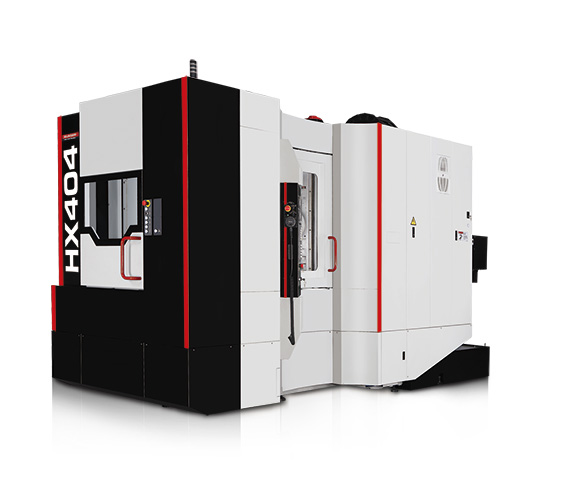

QUASER MACHINE TOOLS, INC.

製品の説明 :

The large Z axis span of HX404 allows the machine to deal with high work pieces and to strengthen machining stability with high rigidity.

The HX404 utilizes W-shaped Z axis telescopic covers to deal with stacked chips, combined with the integrated coolant wash, internal chip augers and external lift up chip conveyor, enhances the management of chip disposal.

In addition, the easy operation and ergonomic accessibility for HX404 allow s operator easily to reach machining work piece, spindle and load/unload station. The HX404 also features small floor space, which makes the best space utilization for clients.

SHE HONG INDUSTRIAL CO., LTD.

製品の説明 :

Intelligent, Specialized in heavy duty cutting

Optimum stability & High rigidity of 3-axes box guideway model

+One of Major 6 Brands of Self-Made NC Controllers Taiwan One and Only Hartrol Premium Controller

+AI intelligent technology Automatic tuning parameter maintains accuracy

+For box guideway model, 50% Quadrant Error reduced and 30% reduction in backlash error

+25% wider width, 15% rigidity increased

+15% ~ 20% machining efficiency better than peers

+30% accuracy better than peers with full stroke support of saddle design, which ensures structure stability and durability

TAIWAN MACHINE TOOL CO., LTD.

製品の説明 :

TMT TG series with meticulous design, is your best choice in precision finishing. Multi-performance, while satisfy different machining demand. Work table can be mounted with APC, 5 Axes or fix table.

-High cutting rigidity with ganty type structure design.

-Compact design less floor occupation.

-Without carring ATC system on moving parts to make it lighter, make sure cutting without vibration.

- Cutting area isolation to ensure the transmission system life longer and easier to install linear scale.

-High efficiency servo drive ATC system, C-C(T1-T2)only 4sec., with high stable performance.

-ATC install at the center of basement to reduce the width of machine to save the walking steps to loading and unloading workpiece.

LEADWELL CNC MACHINES MFG., CORP.

製品の説明 :

The 5 axes simultaneous processing, can reduce the times of workpiece unloading and the requirement of the jigs, shorten the processing time and improve performance. C-axis table using the DD motor provides high torque and rigidity and can solve the traditional worm gear backlash and worn problems. High torque and efficiency of the spindle with a complete high-rigidity structure applied results in roughing to finishing can be completed on the same machine, suitable for machining hard materials and non-ferrous materials processing.

X-axis travel: 1300mm

Y-axis travel: 610mm

Z-axis travel: 610/750mm

Table size: 1480x610mm

Max. table load: 1600kg

Spindle speed: 12000rpm

C-axis speed: 800rpm

X/Y/Z-axis rapid traverse: 36/36/30 m/min

Tool storage capacity: 30T

CAMPRO PRECISION MACHINERY CO., LTD.

製品の説明 :

CAMPRO develops a proprietary system combined with precision tooling/material cabinet to assist customers in managing and analyzing tooling/material usage, 24 hours to get tools or materials and early-warning or alert notifications. The T Series are focus on cutters which is able to adjust the width according to different cutter such as milling, drilling, end-mill, tapping and so on. The patented transmission system allows user to select and dispense, withdraw cutters easily. Available to augment cabinets, max. support 100 cabinets. (Disc Type Cabinet, Tools Holders Cabinet, Recycling Cabinet, Compartment Type Cabinet, and Drawer Type Cabinet)