展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

TAIWAN MORE-CASH VILLAGE CORP.

製品の説明 :

For 3mm-20mm End Mill Re-sharpening , Adjustable Angle

Precise Grinding Results , Precision Assurance within 0.02mm

Center Cutting Available

High Accuracy Balance between each flute of the End Mill

Easy to Operate , grinding an End Mill within 1 minute.

Special Design High Accuracy Alloy Steel Collets

Accurate Grinding consumption 0.2mm

High Efficiency DC motor

Stable Quality Diamond Dust Grinding Wheel

Considerable Design, Invisible Tool Box, Delicate & Friendly Use

Portable Design with only weight 14 kgs.

FALCON MACHINE TOOLS CO., LTD.

製品の説明 :

Chevalier’s FSG-ADIV Series of surface grinders have several design features to shorten your processing and non-processing preparation while delivering high-precision workpieces year after year—functions you might not expect on such affordable machines: iSurface control, variable speed spindle, constant surface speed, loading detection and in-machine manual dynamic balancing.

FSG-ADIV Series grinders also feature tools to secure Big Data with Chevalier’s exclusive iMachine Communications System TM (iMCS).

This software package, combined with data analysis, enhances machine efficiency in the factory while enabling remote monitoring and diagnostics to track machine performance and identify potential problems before they begin.

MATRIX PRECISION CO., LTD.

製品の説明 :

ZHS-3040 combines FANUC controller and PC, it applies linear motors and direct drive motors, developing out the six-axis-control and four-axis-move high-precision grinder. ZHS-3040 can sharpen the blade of straight and helical hobs, it can also sharpen shaper cutters and Power Skiving cutters by options. Self-developed intelligent conversation window software is easy for operation. It meets the brilliant high-precision and high-efficiency performance. One machine with multi- purpose, ZHS-3040 is your best choice.

PERFECT MACHINE CO., LTD.

製品の説明 :

CNC type, Touch panel Rotary table surface grinder

MODEL: PFG-600R

PEIPING PRECISION ENTERPRISE CO., LTD.

製品の説明 :

-Extend the life of holder

-Increase the holder accuracy

-Polish the grease and dirt on holder.

-Once setting for maximum convenience of operating.

GUAN-YU MACHINERY CO., LTD.

製品の説明 :

Double grinding wheel spindle + center frame,

Maximum processing depth 400mm,

X.Y.Z axis travel 800/400/450mm

KING NICE TECH.CO., LTD.

製品の説明 :

▎Use Value reduce the CNC machine failure rate , processing non-performing rate.

▎Water and Coolant Saving.

▎Reduce the cost of CNC mechanical downtime and personnel operations.

▎Maintain the tank liquid caoacity , reduce the temperature rise.

MATRIX PRECISION CO., LTD.

製品の説明 :

2080/3080 applies the FANUC controller and high speed grinding spindle, it will design the tooth profile and grinding parameters flexibly through the intelligent

conversations window software. The machinable workpieces include the standard worms

(ZK, ZI, ZN & ZA), dual-lead worms, ZC (Niemann) worms, thread plug gauges and rolling dies. The high efficiency and high-precision machining performance meet the worldwide top brand products in this field. 2080/3080 is your best choice.

KO-YAN PRECISE MACHINERY CO.,LTD

製品の説明 :

GJ-400 series from COMIRK combines internal grinding and cylindrical grinding in a single machine. Multiple face grinding can be accomplished with one setup for the work-piece. This machine not only saves considerable amount on machine investment costs and labor costs, but it also features dramatically upgrade for better machining efficiency and machining accuracy.

Machine Features

-Various speed of spindles selection allows for the highest grinding efficiency

-Double wheel spindles exhibit high efficiency internal and external grinding

-Internal, external, end face and tapered face can all be ground in one process

-Highly rigid machine structure ensures the best possible stability during grinding

-X, Y, Z axes are all mounted with high precision linear guide-ways.

-This machine is equipped with a FANUC CNC controller

-Multi-face grinding requires only one setup for the work-piece.

-Non-circular grinding function is available (Optional)

-Fully enclosed splash-guard

BENIGN ENTERPRISE CO., LTD.

製品の説明 :

• Hydraulic longitudinal feed. Direction changed by sensor & solenoid valve.

• Automatic cross feed. Direction changed by stopping dog and limit switch.

• Manual vertical feed

• Saddle type

• Automatic lubrication

• Longitudinal: one flat and one V way

• Cross: 2 V way

• Optional AD5 automatic down feed and magnetic chuck

Fulson Industrial Co., Ltd

製品の説明 :

This high precision surface and form grinder has been specially developed and improved in recent years.

The tool cabinet in machine base is specially designed for operator’s convenience (618m).

The interlock between electrical cabinet door and power supply is established to ensure safe operation.

The maximum distance from table surface to spindle centerline is 18" (450mm) which provides more clearance for grinding.

The sping loaded type table travel stops will dampen theovertravel caused by abnormal operations (618m).

The optimum span of double V crossfeed guideways is designedbased on bending moment, kinematics supporting force.

All essential castings are mode of high grade of meehanite castiron that is stress relieved through annealing to eliminateinternal stress.

With the greatest stiffness and stability of the castings, this machine is suitable for both precision surface grinding and formgrinding .

This grinder is offered with one-full-year limited warranty formechanical and electrical parts .

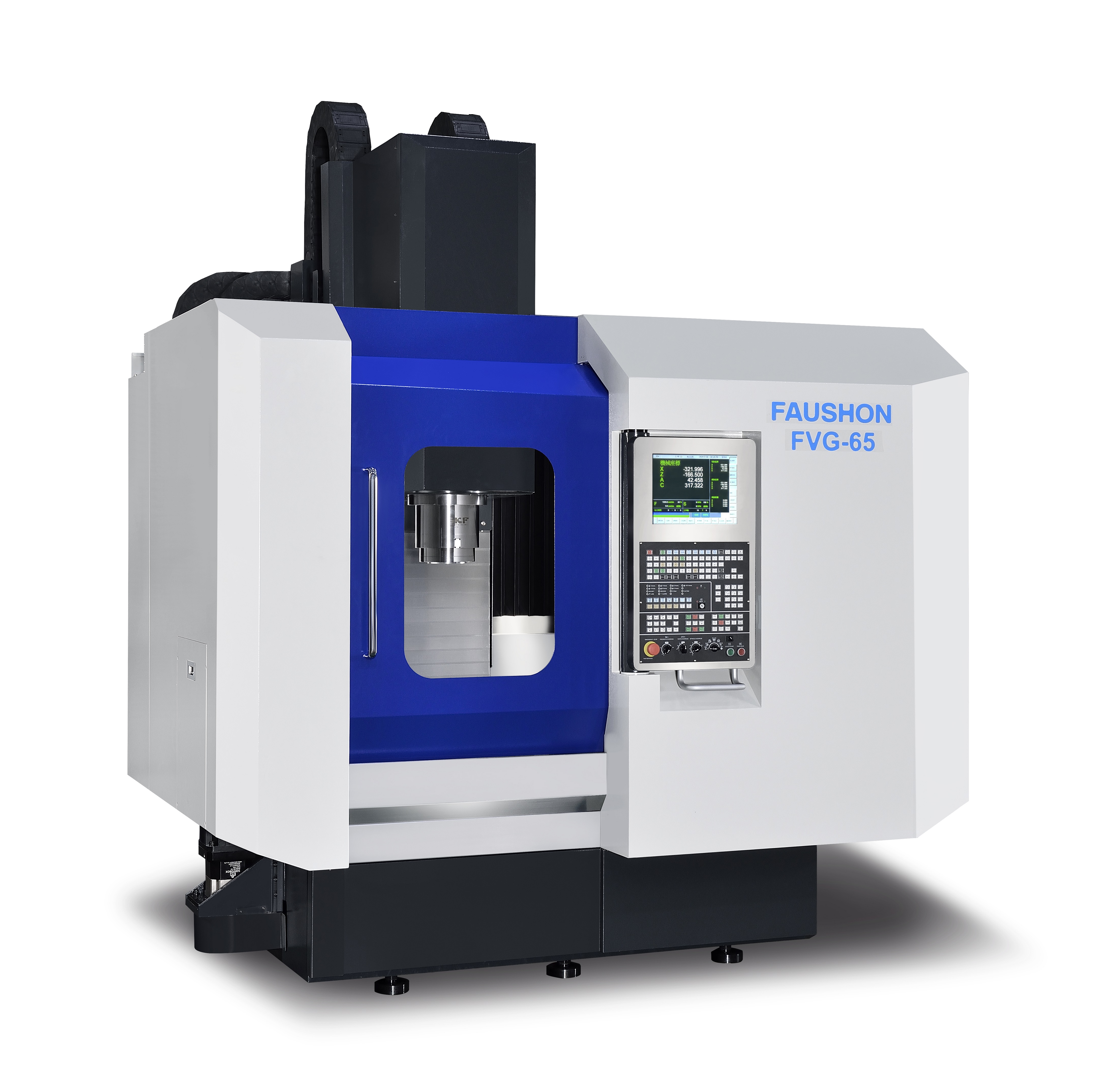

Fulson Industrial Co., Ltd

製品の説明 :

This model is the culmination of years of careful research and development by Faushon. It boasts a sturdy exterior and robust structure, with all operating handles and active control panels designed to be within the operator's optimal range and most comfortable operating position. This design adheres to ergonomic principles, providing you with higher work efficiency.

With our extensive experience in professional grinder manufacturing, we never compromise on accuracy. We can assure you that our machines offer high precision and reliability. We provide a variety of options and solutions to help address on-site challenges. Our machines are capable of multitasking and offer a high cost-performance ratio in terms of accuracy. The main structure design of the machine undergoes thorough finite element analysis and rigorous review of key components to achieve high precision and reliability.