展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

BLUM PRODUCTION METROLOGY CO., LTD.

製品の説明 :

• Measuring speed up to 3 m/min

• Precise, non-lobing touch characteristics

• No-wear, optoelectronic measuring mechanism

• Use of two measuring systems with one IR receiver

• Extended battery life

• Precise measurement even with coolant

• Proven and robust design

TES ELECTRICAL ELECTRONIC CORP.

製品の説明 :

FEATURES :

• 10 Display Easy - to - View LCD Screen.

• Connectors for 4 Current Sensing Clamps.

• 1P2W, 1P3W, 3P3W2M, 3P3W3M & 3P4W Power Measurement.

• True RMS Sensing.

• Power KW, KVAR, KVA, PF,θ,Hz, &

Energy KWh, KVARh & KVAh Measurement.

• Phase sequency indicator function.

• Backlight display function.

• Manual Data Memory and Read (50 sets).

• Data Logging

• USB Optical Interface with three phase voltage /

current Waveform display and Harmonic analysis.

• Easy - to - use Push - Button Operation.

• Light Weight, Portable Design.

ACROW MACHINERY MFG. CO., LTD.

製品の説明 :

Rotating Coolant Union / Grippers (Clamping unit)/ Pallet Clamping Systems / Test Bar / Force Gauge

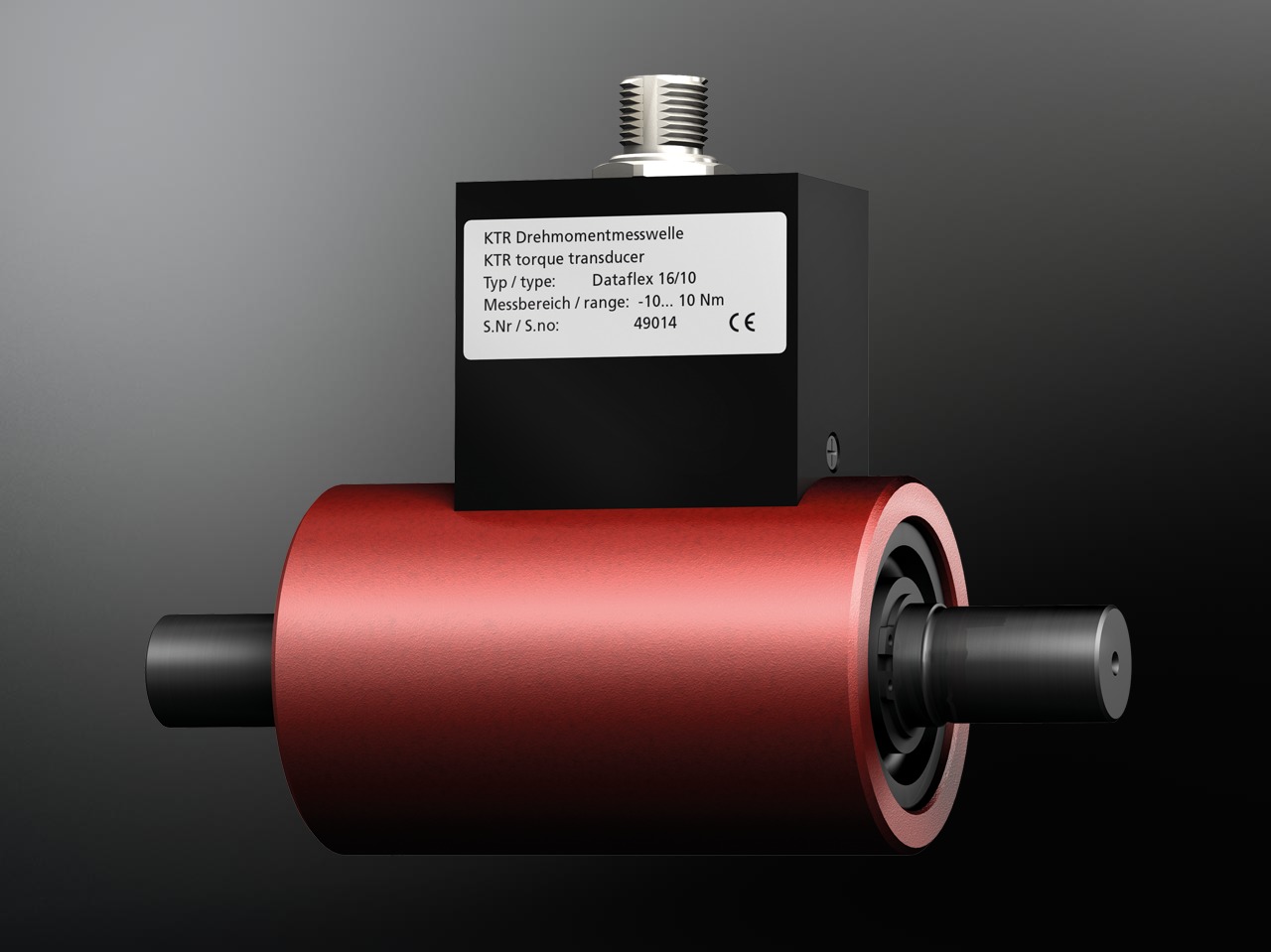

KTR TAIWAN LTD.

製品の説明 :

❙MONITEX BT torque sensor❙

The new MONITEX® BT is a precise tool for daily measuring tasks in test bench technology. With the help of the apps(Android/iOS) or the PC software, torque and speed data can be displayed and saved in a matter of seconds.

1. COST-SAVING- thanks to new integrated design, cost down no longer a dream but a fact.

2. Inaccuracy 0.2%! with wireless BlueTooth coonection, one device get eveyring!

3. SPACER-SAVING- the new measurement coupling can be integrated into the drive in a few simple steps in contrast to classical torque measurement.

4. Error alert- imediate feedback on abnormal data throgh APP

Don't hesitate to call 04-23593278 or send to ktr-tw@ktr.com, both ways are welcome.

BLUM PRODUCTION METROLOGY CO., LTD.

製品の説明 :

Reliable measurement with a wide

range of tool types and sizes

• Superior precision due to latest

measuring mechanism technology

• No subsequent damage due to tool breakage

• Fast ROI

KTR TAIWAN LTD.

製品の説明 :

The recently developed DATAFLEX® 16 is available for measuring torque ranges of 10 Nm, 30 Nm and 50 Nm. The torque is measured using the well-approved technology of wire strain gauges combined with the latest electronic components.

The torque signals are processed without contact at a high resolution of 24 bit achieving an accuracy of 0.1 % of the terminal value. Supplementary to torque measuring the size 16 has a speed encoder providing two signals with a resolution of 360 pulses per revolution.

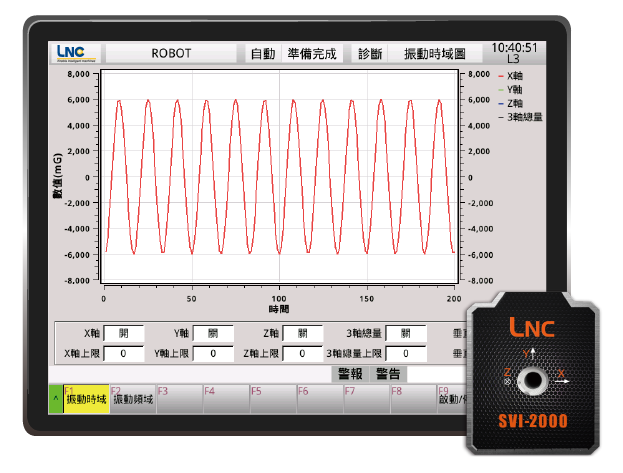

LNC TECHNOLOGY CO., LTD.

製品の説明 :

‧Low profile, high performance, easy installation, high applicability

‧High sensitivity, high precision

‧measurement:±16G, extremely low signal /noise ratio

‧XYZ three-axis vibration detection

‧Measuring frequency 3.32kHz(max.)

‧EtherCAT protocol

‧Water and oil proof, great anti-interference ability

‧Support time domain graph, frequency domain graph, abnormal vibration section marking of program function

‧Support smart function development: Broken tool detection, abnormal vibration detection, spindle protection, tool wear, adjustment assistance, equipment health inspection, etc.

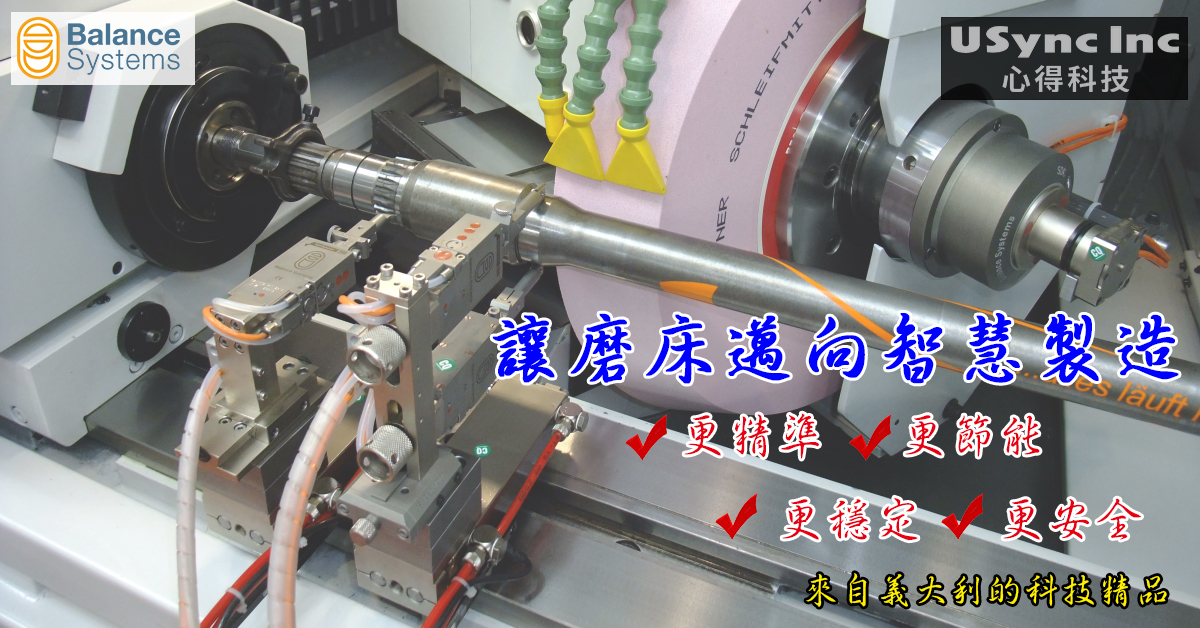

USYNC INC.

製品の説明 :

"VM25" is a high-performance application of a fully modular system designed for grinding machines, including automatic balancing on the 1 and 2 sides of the grinding wheel spindle, the use of audio detection to control the contact of the grinding wheel to the workpiece or sand, online Measurement and off-line measurement (absolute or relative) and other functions.

"B-Safe" can provide vibration and temperature information of the main shaft to detect and monitor the status analysis of the main shaft and machine. It is a new thinking product for intelligent monitoring. Its miniaturized volume design helps to install directly on the main shaft, ensuring that it can provide immediate monitoring of abnormal operating conditions, further predicting the timing of maintenance and failures, protecting your machine and reducing downtime.

BLUM PRODUCTION METROLOGY CO., LTD.

製品の説明 :

– THOUSANDS OF MEASURING VALUES OF ALL TOOL CUTTING EDGES PER SECOND

– UP TO 60% LESS MEASURING AND CHECKING TIME

– MEASUREMENT AND MONITORING OF ALL KINDS OF TOOLS, TOOL FORMS AND CUTTING MATERIALS

– COMPENSATION OF SPINDLE DRIFT AND TOOL CUTTING EDGE RUN-OUT ERRORS

EQP SERIES CO., LTD

製品の説明 :

This system is versatile and can be used not only for general vibration monitoring but also for measurements in challenging environments and is compatible with intrinsic safety and explosion-proof requirements. The Vibrating Converter MODEL-2503 is a system that can accommodate various sensors and specifications.

A vibration monitoring system using the Intrinsic Safety Explosion-proof Detector MODEL-2450EX is composed of detectors, barriers (safety retainers), and MODEL-2503 installed in hazardous locations.

The output includes not only DC4-20mA but also two systems of vibrating waveform AC±2V. This allows not only observation on digital monitors but also connectivity to various PLCs, contributing to the IoT compatibility of facilities.

Can be used in conjunction with the high-sensitivity piezoelectric accelerometer MODEL2430.

G-TECH INSTRUMENTS INC.

製品の説明 :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"