展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

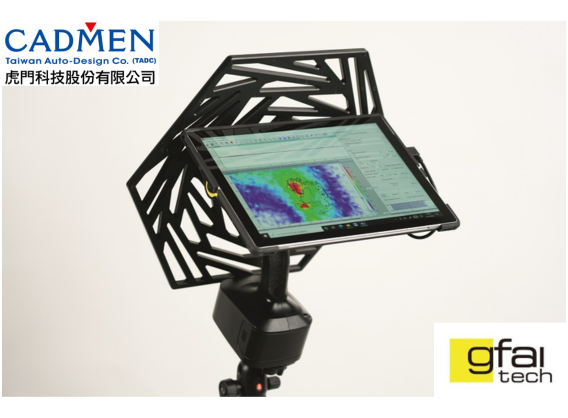

Taiwan Auto-Design Co.

製品の説明 :

德國 Gfai tech 是量測設備的領導者,長期專注於聲音與振動的量測設備開發並提供可視化產品與服務。其結構動態 (Structure Dynamics) 應用產品,確保客戶從聲音與振動結合的量測數據中獲得更多知識用於解決工程問題。

Key Benefits

► Gfai Tech/ Mikado 是解決噪音與振動問題的完善解決方案

► 觸碰螢幕與手動觸發按鈕等特性確保快速與簡單操作

► Mikado系統包含快速及有效聲學量測與分析所需的所有組件

► 可透過設備直接記錄數據與進行基於頻域與時域的基本分析

► 全移動裝置使得幾乎可從任何位置進行量測

► 系統陣列帶有整合的Intel® RealSense™ 超高畫質(Full HD)解析度景深攝影機與記錄深度訊息能力

BLUM PRODUCTION METROLOGY CO., LTD.

製品の説明 :

• Measuring speed up to 3 m/min

• Precise non-lobing touch characteristics

• No-wear, optoelectronic measuring mechanism

• Easy pairing procedure between probe and receiver

• Use of up to 6 measuring systems with one receiver

• Extended battery life

• Precise measurement even with coolant

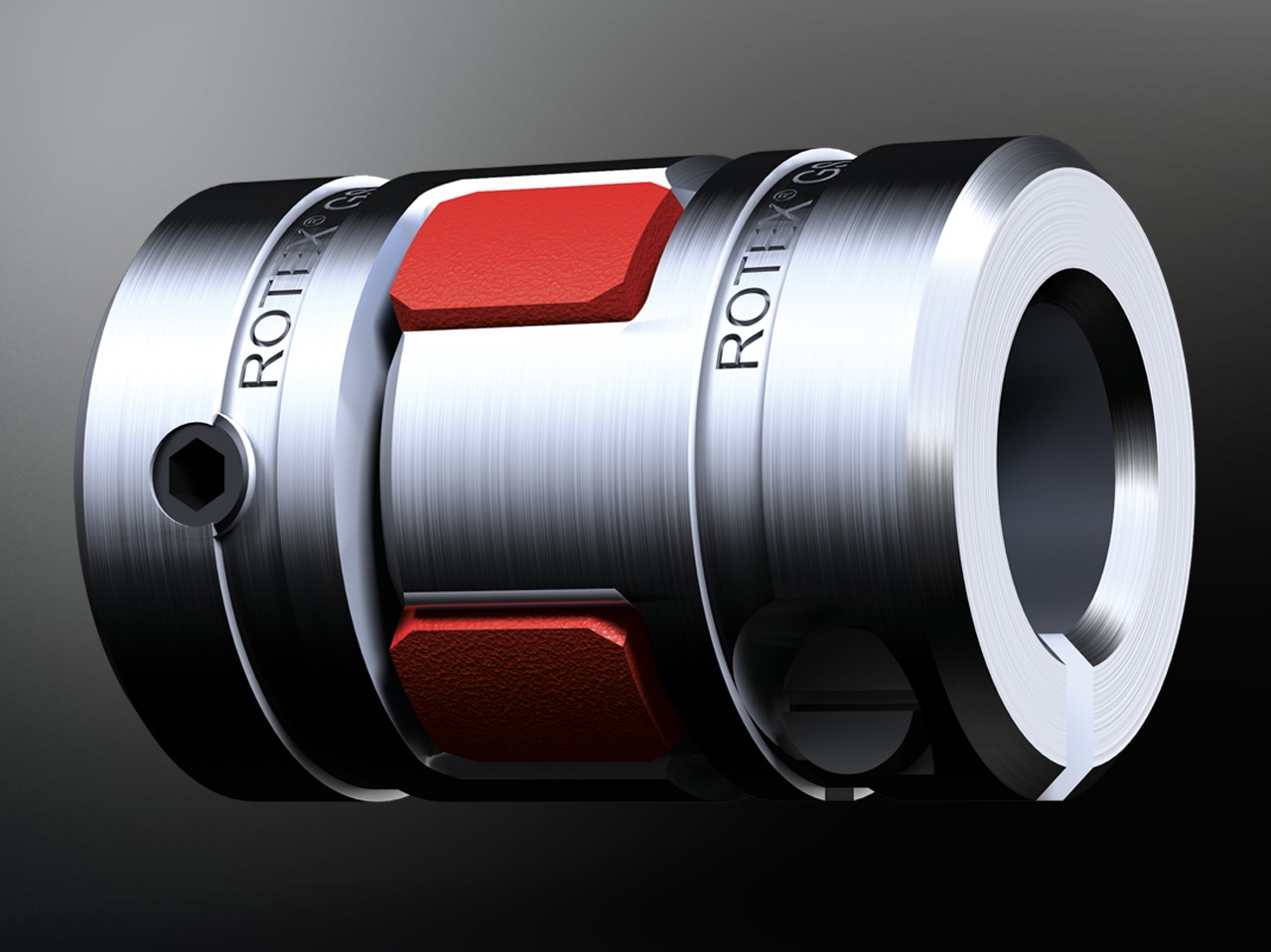

KTR TAIWAN LTD.

製品の説明 :

ROTEX® GS is a three-part coupling, backlash-free under pre-stress. The different hub designs and the different Shore hardnesses offer the optimal coupling for each application in automation engineering. In spite of its vibration-damping characteristics it is torsionally stiff so that it is not necessary to make any concessions to accuracy even with highly dynamic servo drives. The ROTEX GS works with the modular system; a high variety of different hub designs is available which can be combined within one coupling size.

EQP SERIES CO., LTD

製品の説明 :

Voltage Sensitivity: 10mV/(m/s²)±10%

Power Supply: DC15~36V

Constant Current: 0.5~10mA

Resonant Frequency: Approximately 40kHz

Frequency Response: 5~10kHz (±3dB)

Maximum Acceleration: 220m/s²

Shock Resistance: 49,000m/s²

Noise Level: Below 100μVRMS

Operating Temperature Range: -50~110℃

Detection Structure: Shear Type

Case Material: Titanium

Mass: Approximately 10g

RAISE PRECISION CO., LTD.

製品の説明 :

Capacitive switches with touch sensor technology

The first capacitive switches with touch sensor technology from CAPTRON were used in 1994 for public transportation. Today, CAPTRON offers a wide range of capacitive SENSORswitches for various industries and applications where unconditional reliability, durability, comfort and design are required.

If necessary, SENSORswitches from the standard range can be tailored and modified optically and technically to meet individual customer demands.

EQP SERIES CO., LTD

製品の説明 :

任何人都可以輕鬆測量振動。 實現超小型、簡單、實用、快速的測量。

手持式便攜型振動計。

Hi/Lo 靈敏度切換,可以進行較寬範圍之測量

加速度測量範圍為0.01m/s2 至199.9m/s2

速度測量範圍為0.01mm/s 至199.9mm/s

位移測量範圍為0.001 至19.99mm(P-P)

使用兩節 AA 鹼性電池,可連續使用 30 小時以上。

所有附件(如觸針、磁鐵、安裝螺釘和手提箱)均作為標準配置提供。

它符合振動烈度測量設備標準JIS B 0907,能夠確定旋轉機械等的質量。

通過各種擴展選項可以進行振動波形記錄和頻率分析。

符合歐洲CE規範之產品。

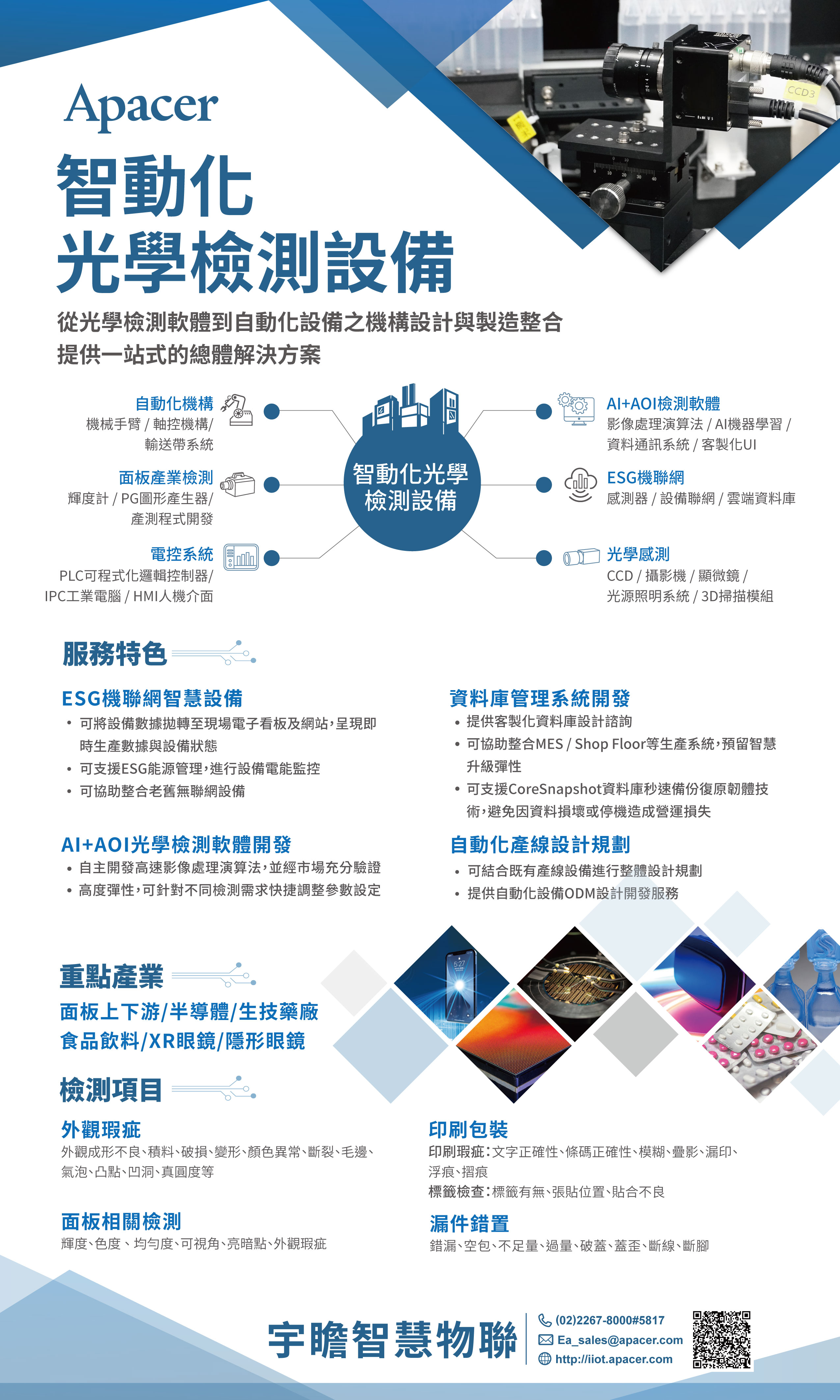

APACER TECHNOLOGY INC.

製品の説明 :

從光學檢測軟體到自動化設備之機構設計與製造整合

提供一站式的總體解決方案。

客製化規劃,專業設計開發AI+AOI光學檢測機台,可串連現有機台,設計全新自動化流程,提升瑕疵檢測的效率、降低人力成本。適用於面板業、生技藥廠、半導體、食品飲料等產業的各式瑕疵檢測應用。

瞭解更多:https://iiot.apacer.com/tw/optical-inspection/ai-aoi-automation/

更多實績案例,歡迎參考Apacer宇瞻智慧物聯官網:https://iiot.apacer.com/tw/case-studies/

DA CEI TRADE CO.,LTD.

製品の説明 :

Low pressure loss! Low cost! Light!

Compressor and high pressure blower are unnecessary!

Air-speed 100m/s can be discharged by the turbo-blower.

APACER TECHNOLOGY INC.

製品の説明 :

結合各大廠牌光學量測儀器與機械手臂,輔以高度客製化軟體,實現高精度之多點、多角度光學量測,可滿足所有面板、背光模組或LCM模組等光學量測需求。

瞭解更多:https://iiot.apacer.com/tw/optical-inspection/ai-aoi-automation/

更多實績案例,歡迎參考Apacer宇瞻智慧物聯官網:https://iiot.apacer.com/tw/case-studies/

ACROW MACHINERY MFG. CO., LTD.

製品の説明 :

Rotating Coolant Union / Grippers (Clamping unit)/ Pallet Clamping Systems / Test Bar / Force Gauge

YINSH PRECISION INDUSTRIAL CO., LTD.

製品の説明 :

『軸向力感測器』,是由其研發設計中心暨精密螺帽檢測實驗室所設計開發測試,為目前市面上專屬為主軸用精密螺帽設計之預壓感測器,其功能正是用以測量精密螺帽在鎖緊時,施予扭力後會有多少軸向力施壓在被鎖物上,除此之外,還可自行檢查主軸在組裝時的品質是否穩定,進行預壓值數據之比對,目前產品提供三種規格,並配合實驗級別之上下墊圈,可測量M40至M170之螺帽軸向預壓,其可量測之最大預壓力為4000kgf,且已申請相關國內外專利

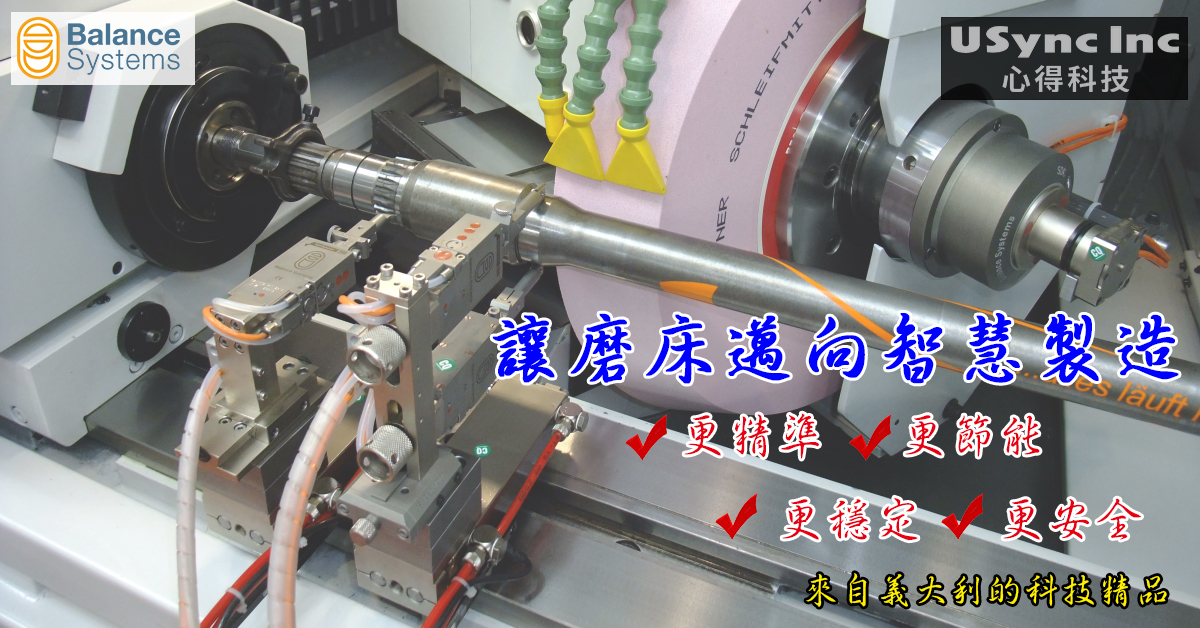

USYNC INC.

製品の説明 :

"VM25" is a high-performance application of a fully modular system designed for grinding machines, including automatic balancing on the 1 and 2 sides of the grinding wheel spindle, the use of audio detection to control the contact of the grinding wheel to the workpiece or sand, online Measurement and off-line measurement (absolute or relative) and other functions.

"B-Safe" can provide vibration and temperature information of the main shaft to detect and monitor the status analysis of the main shaft and machine. It is a new thinking product for intelligent monitoring. Its miniaturized volume design helps to install directly on the main shaft, ensuring that it can provide immediate monitoring of abnormal operating conditions, further predicting the timing of maintenance and failures, protecting your machine and reducing downtime.