展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

EQP SERIES CO., LTD

製品の説明 :

Connect various vibration meters for vibration analysis.

It is a waveform acquisition and analysis software capable of handling up to 32 channels.

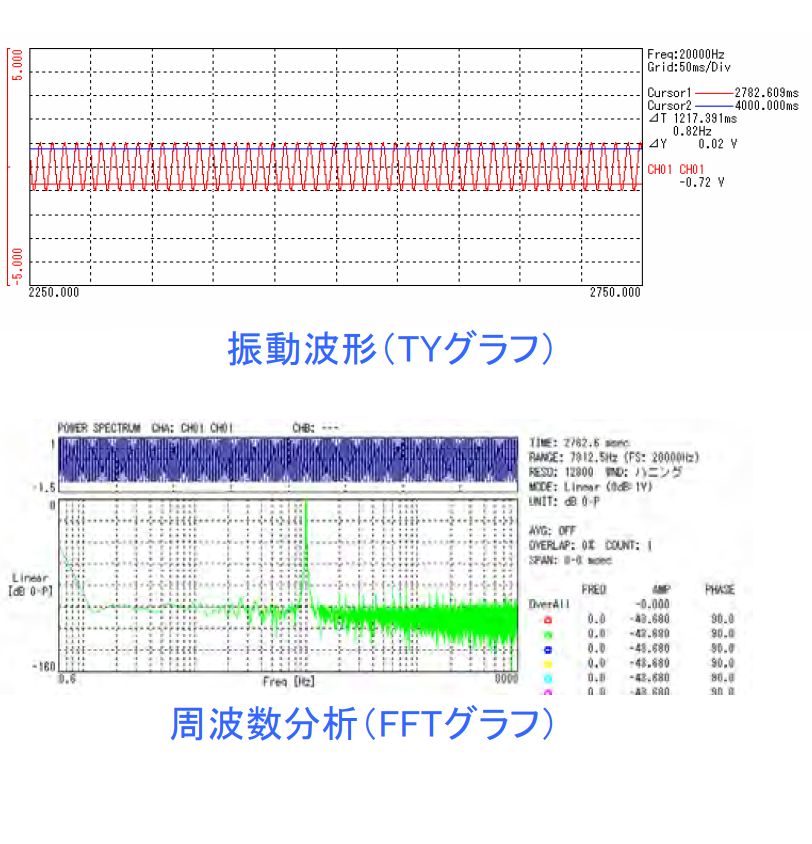

It provides waveform (TY) graphs, FFT graphs, XY graphs.

Real-time or post-processing waveform analysis is possible.

You can add any filters or perform recalculations in post-processing.

It also allows for audio playback of waveform data.

Compatible with various types of vibration meters.

Samwell Testing Inc.

製品の説明 :

PSV QTec Scanning Vibrometers take full-field vibration mapping to the next level with unrivalled optical sensitivity! Their innovative, patented QTec® technology uses multi-path interferometry based on infrared (SWIR) laser granting high-fidelity measurements on all surfaces from DC to 25 MHz. PSV QTec significantly reduce testing time - especially on dark, biological, rotating or moving objects, determining operational deflection shapes and Eigenmodes for NVH, acoustics, structural dynamics, ultrasonics, FEM validation and NDT.

TES ELECTRICAL ELECTRONIC CORP.

製品の説明 :

FEATURES :

• 10 Display Easy - to - View LCD Screen.

• Connectors for 4 Current Sensing Clamps.

• 1P2W, 1P3W, 3P3W2M, 3P3W3M & 3P4W Power Measurement.

• True RMS Sensing.

• Power KW, KVAR, KVA, PF,θ,Hz, &

Energy KWh, KVARh & KVAh Measurement.

• Phase sequency indicator function.

• Backlight display function.

• Manual Data Memory and Read (50 sets).

• Data Logging

• USB Optical Interface with three phase voltage /

current Waveform display and Harmonic analysis.

• Easy - to - use Push - Button Operation.

• Light Weight, Portable Design.

POWERIN ENTERPRISE CO.,LTD.

製品の説明 :

寶膺提供專業代理,德國工業相機領導品牌 IDS Imaging Development Systems的各項產品,專注於 2D 與 3D 的視覺應用與解決方案,提供客戶專業優質的服務!

G-TECH INSTRUMENTS INC.

製品の説明 :

A rotor that does not perform dynamic balance correction may produce unnecessary vibrations and thus reduce the productivity of the machine, as well as damage to the bearings. At the same time, it may cause damage to the outer frame or supporting device and foundation during severe movement.

G-Tech HJ-4250S-A Hard Bearing Balancing Machine is applicable for tool machine spindles, high-speed built-in spindles, motor rotors / motors, rollers, fans, centerless grinding wheels.

A maximum rotor weight of 500kg, a maximum rotor diameter of 1 meter, and measurement accuracy at low speed dynamic balance is 0.5gram-mm(max), and the can be 0.05gram-mm(max) at high-speed dynamic balance.

TES ELECTRICAL ELECTRONIC CORP.

製品の説明 :

■ Measures acceleration, Velocity and displacement

■ Maximum/Minimum record function

■ Earphone output for detecting noise in machine components

■ Manual memory stores up to 99 data

■ RMS, EQ PEAK and EQ P-P measurement

■ Wide range of vibration measurement by using different sensitivity of accelerometers

■ Excellent accelerometer for harsh environments

RAISE PRECISION CO., LTD.

製品の説明 :

The compact, high-resolution MiniCODERs have proven their value for speed and position acquisition in highly dynamic applications. They use their full potential when installation situations with little space require a particularly compact, robust and reliable measuring system. The magnetic measuring systems consist of a ferromagnetic target wheel and a scanning unit. Without dedicated bearings, they are completely wear-free and maintenance-free. The optimised circuit and screening technique, and fully encapsulated electronics ensure reliable operation even in harsh environments.

PAUL YANG PRECISION TECH CO., LTD.

製品の説明 :

FULL Function Online balancer :

Vibration Meter / Speed Meter / Balancer / Vibration Monitor

Suit for all precision machines:

rotary-table grinder, surface grinder, cylindrical grinder, inner diameter grinder, vertical grinder, tool grinder,gear grinder, centerless grinder, machine center, mold processing machine, five-axis machine, vertical NC lathes, horizontal NC lathes, Turning & milling machine, High speed rotary-table...

G-TECH INSTRUMENTS INC.

製品の説明 :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"

KTR TAIWAN LTD.

製品の説明 :

❙MONITEX BT torque sensor❙

The new MONITEX® BT is a precise tool for daily measuring tasks in test bench technology. With the help of the apps(Android/iOS) or the PC software, torque and speed data can be displayed and saved in a matter of seconds.

1. COST-SAVING- thanks to new integrated design, cost down no longer a dream but a fact.

2. Inaccuracy 0.2%! with wireless BlueTooth coonection, one device get eveyring!

3. SPACER-SAVING- the new measurement coupling can be integrated into the drive in a few simple steps in contrast to classical torque measurement.

4. Error alert- imediate feedback on abnormal data throgh APP

Don't hesitate to call 04-23593278 or send to ktr-tw@ktr.com, both ways are welcome.

RAISE PRECISION CO., LTD.

製品の説明 :

CAPTRON, pioneer of the first capacitive two-hand control system, ensure the highest safety category according to (Cat. 4) and PL e (DIN EN ISO 13849-1). The capacitive "safeCAP" two-hand control allows heavy machinery and systems in automated production plants, such as presses and punches, to be controlled safely and without pressure.

To start the machine the user simultaneously presses two capacitive buttons which are connected to a safety relay. Incorrect or inattentive control using just one hand or with another part of the body is detected by the system and the machine is not started.

CAPTRON supplies the safeCAP two-hand control with additional safety elements such as the Protector or the control desk for tabletop installation. These combinations enhance protection and are certified to DIN EN 574. The dynamically switching SENSORswitches detect interference factors such as dirt, dust or foreign bodies. The switches can be actuated using disposable or work gloves, however.