展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

YIH KUAN ENT CO., LTD.

製品の説明 :

The CNC Milling Head can tackle all sorts of critical processes, such as rough milling, finishing milling, boring holes, and much more. It's easily compatible with a number of different machines, like computer gantry milling machines, machining centers, and so on. Don't let small spaces or tight curves slow down your projects - the CNC Milling Head is compact enough to fit even into the most complex of workspaces. Plus its precise performance ensures that you get results exactly how you need them - every time. With the CNC Milling Head you can take your machining to the next level while saving time and money in the process.

1. The IK milling head, which fits your current milling machines and special purpose machines, can take place of your current milling heads and upgrade your machines.

2. This product with gear-type construction is very powerful and can creat a maximum machining efficiency for you

3. Spindle speed change has high and low two stage.

4. This product can be installed to a computer-controlled vertical milling machine and a special purpose machine.

5. This products doesn't include a servo motor or servo controller.

6. The IK CNC milling head series has three kinds of products.

BUFFALO MACHINERY CO., LTD.

製品の説明 :

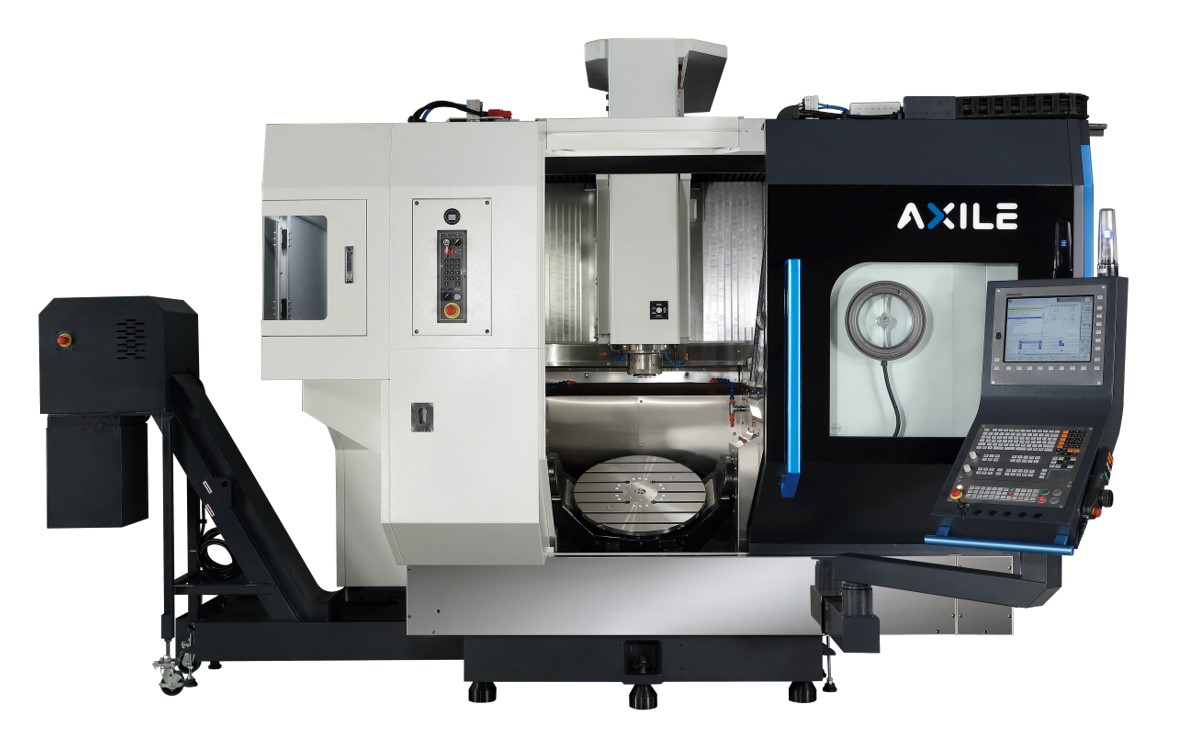

The DC12 is the most robust VMC in AXILE’s arsenal, perfectly suited for handling larger, lengthy workpieces. With a maximum table loading weight of 2.5 tonnes and maximum diameter of 2,200 mm X 1,200 mm, the DC12 takes on the larger, heavier parts common in the aerospace, power generation, and die and mold industries. Its double-column bridge construction allows for greater rigidity, as well as greater control over thermal deformation. As a result, the D12 is capable of deep cuts and complex contouring while maintaining utmost precision.

With larger workpieces come more chips, meaning the DC12 features excellent chip removal efficiency, to prolong tool life and ensure no residual interference. Therefore, the DC12 delivers the high surface quality expected by leading manufacturers.

HEIDENHAIN CO., LTD. (TAIWAN)

製品の説明 :

In addition to milling operations, the TNC 640 also combines operations from milling, turning, and grinding processes. This sets the TNC 640 apart as a high-end control within its field of application. It is particularly well suited to HSC and 5-axis simultaneous machining, including on fully automated machining centers. The TNC 640 stands for perfect surface quality, exceptional accuracy, and very short machining times combined with shop-friendly operation and programming. On a milling/ turning machine with TNC 640, you machine the complete work piece on one machine in whatever sequence is needed. You can switch back and forth regardless of the machine and its axis configuration. The TNC 640 makes all necessary adjustments, e.g. switching to diameter display and setting the datum in the rotary table center. Batch Process Manager allows you to optimally plan and execute production jobs with great ease. With Batch Process Manager you can flexibly define the sequence of your jobs and, prior to machining, check to ensure that all of the required tools are available and that the NC program will run without errors.

HC FENG CO., LTD.

製品の説明 :

FOODIE (Chip/Sludge Removal Machine) works for :

Filtration/Removal of excess components

Chip/Sludge Removal

Fine Chip Removal

No downtime

No consumables

Backwater automatically & simultaneously

Air pressure drive w/o a plug

Vertically fast filter drying up to 90% efficiency

Precision filters effective up 20% for super filtration micro-fines

Easy to move

Filter accuracy can be adjusted

Extend cutting fluid life

CHIEN CHENS MACHINERY CO., LTD.

製品の説明 :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

A axis travel: 370 mm

Y slide way width: 720 mm

Z Slide high: MAX 700 mm

Z Slide way width: 420 mm

Spindle taper: NT#40(BT)

Spindle motor: 5HP / 4P

Spindle speed: 70~3600 RPM

Horizontal Spindle motor: 5HP / 4P

HorizontalSpindle speed: 70~3600 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3500 kgs

FUI JET TECH CO., LTD

製品の説明 :

The zero-point positioning system is a normal clamping mechanism, which is opened during ventilation and the air pressure is cut off. When the zero-point positioning system is ventilated, the pressure will pass through the compressed spring inside the piston, causing the piston to rise, and the steel balls can retreat toward the water pump. When the air source is turned off, the spring will push back the piston, and the piston handle will The steel ball is pushed toward the middle, causing the ladder bolt to

BUFFALO MACHINERY CO., LTD.

製品の説明 :

With a rotary table diameter of 600 mm, the G6 is a compact vertical machining center designed for agile, smart machining of smaller workpieces requiring complex geometries and intricate features. This highly versatile VMC delivers full 5-axis CNC machining, with the built-in spindle moving along the X,Y,Z-axis, and the table moving in rotary C-axis and swiveling A-axis.

The G6’s perfect balance of speed and precision makes it the perfect option for job shops and production lines seeking an upgrade in machining capabilities, delivering high removal rates, excellent surface finishes, and maximum production efficiency.

In addition to the high-performance G6 model, AXILE also offers the G6 MT, which combines both milling and turning in one machine, greatly increasing operational flexibility. By reducing set-up times and potential clamping errors, the G6 MT can efficiently machine a wider variety of parts, including cylindrical components.