展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

FUI JET TECH CO., LTD

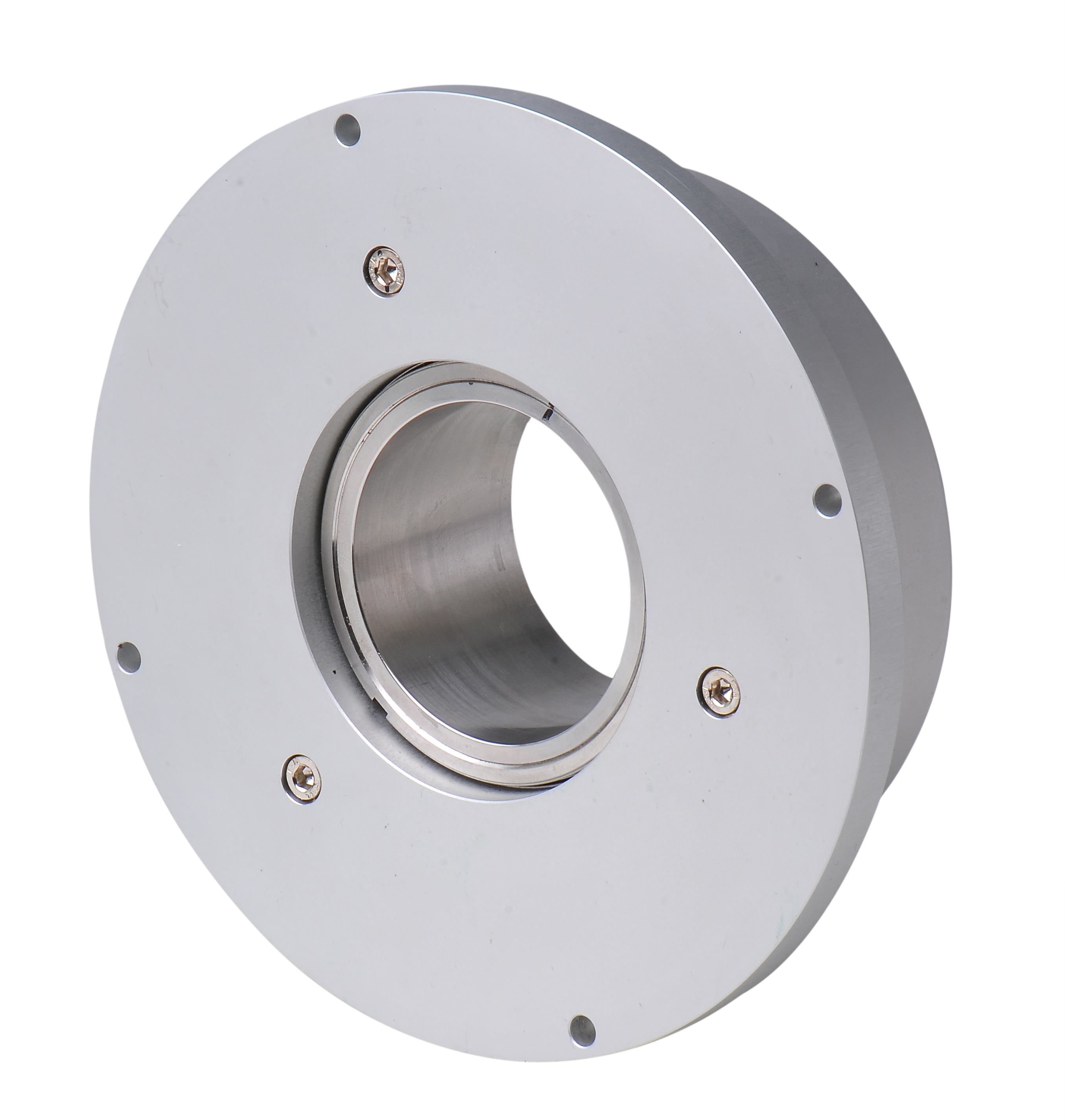

製品の説明 :

The zero-point positioning system is a normal clamping mechanism, which is opened during ventilation and the air pressure is cut off. When the zero-point positioning system is ventilated, the pressure will pass through the compressed spring inside the piston, causing the piston to rise, and the steel balls can retreat toward the water pump. When the air source is turned off, the spring will push back the piston, and the piston handle will The steel ball is pushed toward the middle, causing the ladder bolt to

VISION WIDE TECH CO., LTD.

製品の説明 :

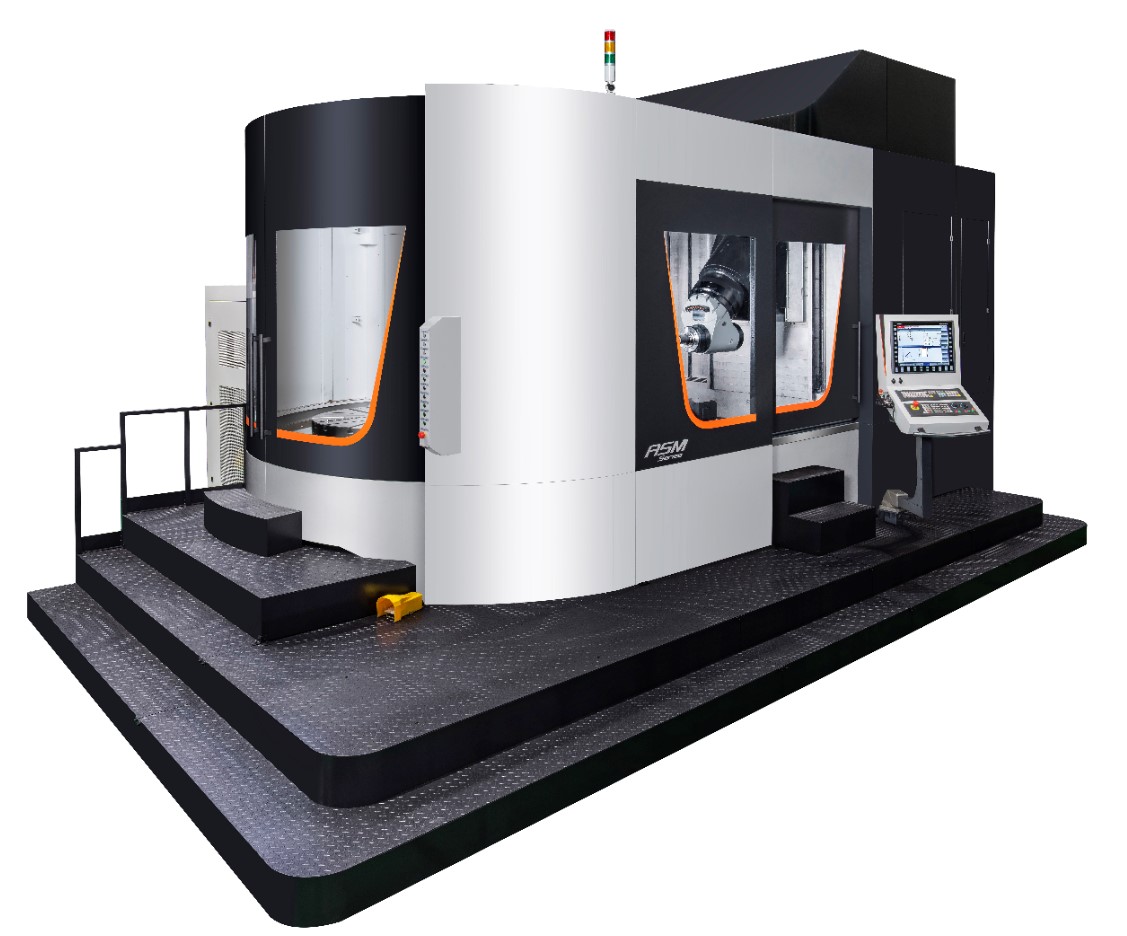

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min

SGCAM TECHNOLOGY CO., LTD.

製品の説明 :

主功能介紹:<br />

全中文畫面,易學、易懂、易用,為加工業最適合的加工軟體,操作軟體完全不用背指令。<br />

可由AutoCAD製圖畫出工件外形,再匯入DXF圖檔,轉換為CNC程式碼。<br />

參數式的加工資料設定,作CAM只需三個步驟:(1)選擇工法(2)指定加工參數(3)計算、轉出加工G碼。<br />

參數式的資料設定,圖形改變後,加工碼會自動隨之改變。<br />

智慧型功能:<br />

工法和加工的輪廓可直接複製修改,不必再重新指定。<br />

自動清角可自動清除前一把刀具,所留下來的角落殘料。<br />

鑽孔時依據孔徑大小,自動搜尋鑽孔的加工位置,不必每一孔都去點選指定。<br />

字型可自動截割輪廓外圍不用慢慢編修。<br />

支援單筆劃字型刻字。<br />

加工路徑最佳化,各加工路徑間依最短距離自動計算,且可指定各加工路徑間不提刀以縮短加工時間,達到最佳之加工效率。<br />

立體加工: 不必畫3D曲面圖形就可做出立體加工工法,簡單夾治具可自行製作。<br />

牽引面加工:可加工彎管、簡單的立體。<br />

規則面加工:規則斜面、四角錐面、圓錐面。<br />

旋轉面加工:圓球面、葫蘆形狀。<br />

Z軸投影加工:可在不等高的平面上作投影加工。

KCW ETERNAL ENTERPRISE CO., LTD.

製品の説明 :

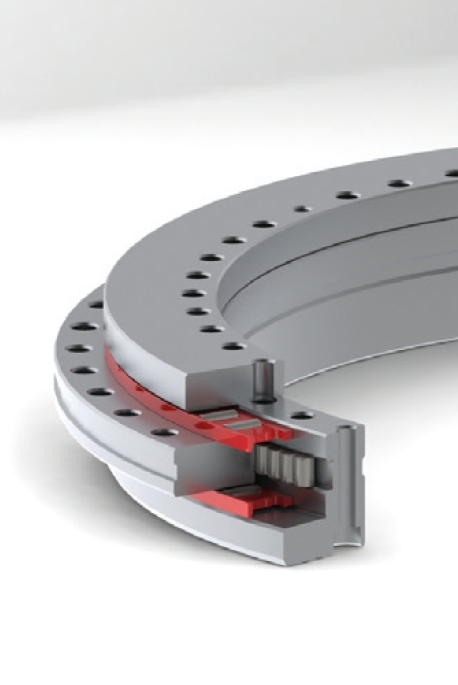

Features: High rigidity, high rotational accuracy, high geometric quality

Compatible with market standard products, short delivery time

The perfect solution for high positioning accuracy requirements:

Rotary tables and indexing plates, integrated processing machines, Milling machines, drilling machines, Machining Center

BUFFALO MACHINERY CO., LTD.

製品の説明 :

The DC12 is the most robust VMC in AXILE’s arsenal, perfectly suited for handling larger, lengthy workpieces. With a maximum table loading weight of 2.5 tonnes and maximum diameter of 2,200 mm X 1,200 mm, the DC12 takes on the larger, heavier parts common in the aerospace, power generation, and die and mold industries. Its double-column bridge construction allows for greater rigidity, as well as greater control over thermal deformation. As a result, the D12 is capable of deep cuts and complex contouring while maintaining utmost precision.

With larger workpieces come more chips, meaning the DC12 features excellent chip removal efficiency, to prolong tool life and ensure no residual interference. Therefore, the DC12 delivers the high surface quality expected by leading manufacturers.

HEIDENHAIN CO., LTD. (TAIWAN)

製品の説明 :

Angle encoders for rotary and tilting axes are indispensable for machine tools on which high positioning accuracy and a high machining rate are essential. Because angle encoder measure angular motion of the axis directly and immediately. Mechanical transfer elements therefore have no influence on position measurement, both kinematics errors and the influences of forces are measured by the angle encoder and considered in the position control loop. This can eliminate a number of potential error sources: Gear errors, reversal error, errors due to deformation of the drive mechanics by machining forces.

REN AN INFORMATION TECHNOLOGY CO., LTD.

製品の説明 :

Guided-steps CAD/CAM with Machining Simulation including tool path verification and machining time.

Excellent tool for learning CAD/CAM and verifying with simulation.

HC FENG CO., LTD.

製品の説明 :

Replenishing Fluid automatically, accurate cutting fluid concentration. One equipment to multiple CNC machining centers. The supply line can be as long as 20 meters.

#Filtration by 3 filters #Sterilization by ozone # Oil-water mixer to precise mixing 0-10% cutting fluid #Stirring device avoid cutting fluid become stagnant water. #oil tank level meter for 50 gallon barrel low level detection.