展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

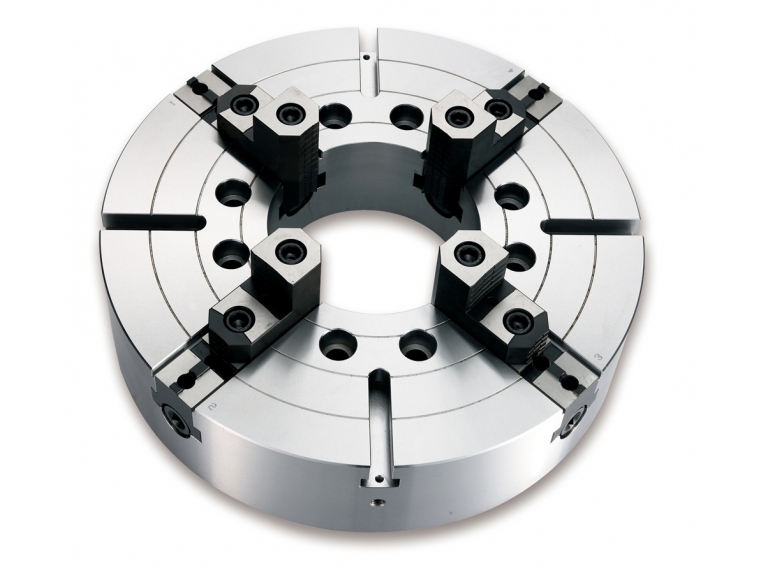

YANMECH Industrial Co., Ltd.

製品の説明 :

【J Series:】

1. Adapter Plates can be selected.

2. Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

3. The jaw can be individually operated, and irregularly shaped workpieces can be clamped.

4. Special specifications can be customized.

【L Series:】

1. Adapter Plates can be selected.

2. The jaw can be individually operated, and irregularly shaped workpieces can be clamped.

3. Special specifications can be customized.

CLAMPTEK ENTERPRISE CO., LTD.

製品の説明 :

🔹The optimized design of the accessories of CHA / CHA-P series makes the structure more compact and increases the product strength.

🔹 CHA / CHA-P series equipped with special dustproof design and have high sealing performance.

🔹The designation of high anti-torque makes the durability long.

🔹 Max. operating pressure:70 kgf/cm²

Min. operating pressure:15 kgf/cm²

🔹Double acting

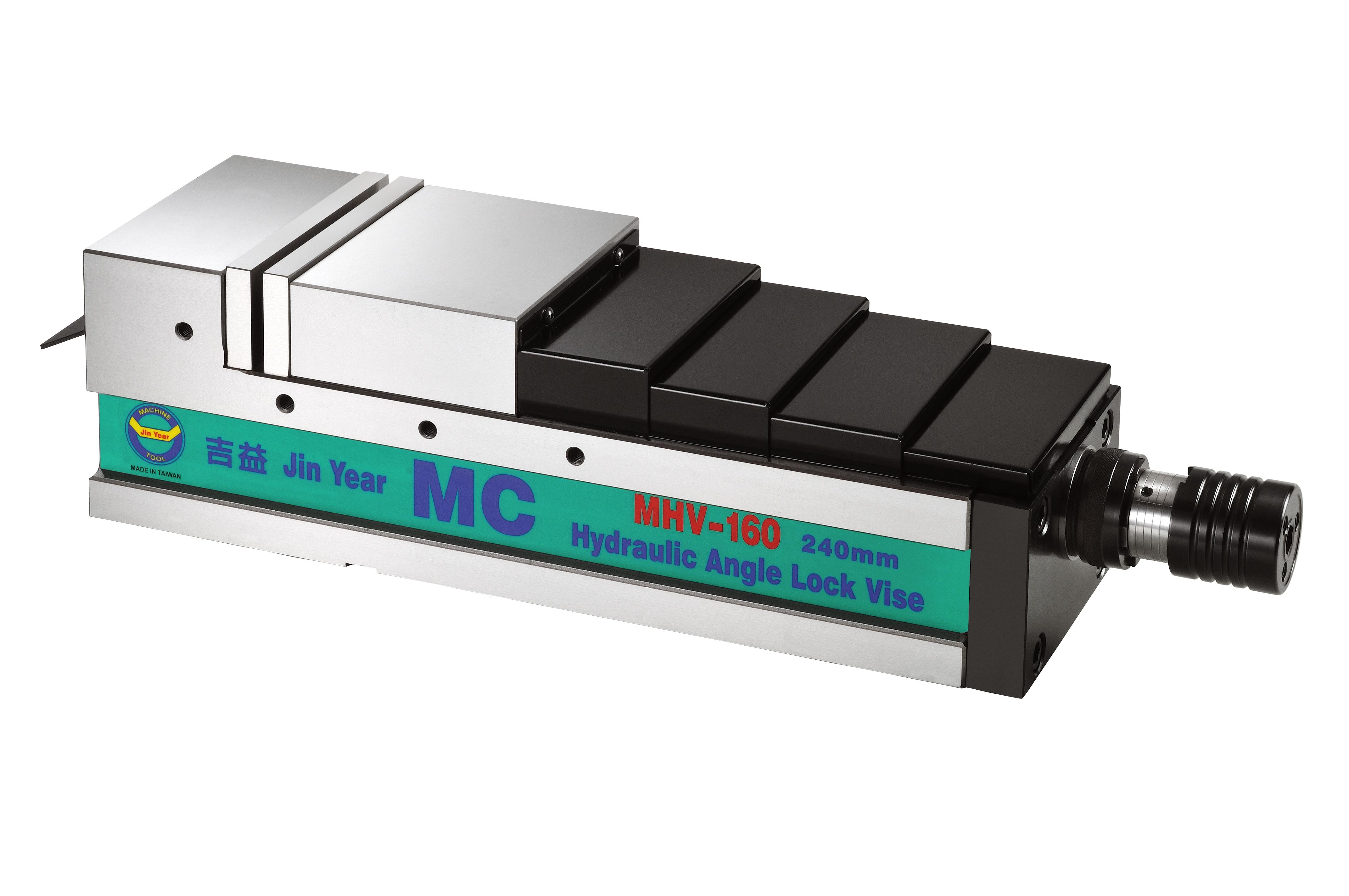

JIN YEAR PRECISION CO., LTD.

製品の説明 :

1.Down thrust with"semi-sphere"to prevent workpiece lift.

2.Mechanical/Hydraulic. Two operate methods.

3.Vise body is made of ductile iron FCD-60.

4.Vise bed hardened to HRC45 and maintain accuracy for long.

5.Vise bed height-size and the guide block side are all made with full control, can 2.3 or 4 vises to perform a job at a time.

6.Vise have 4 ways of clamping. For you to choice.

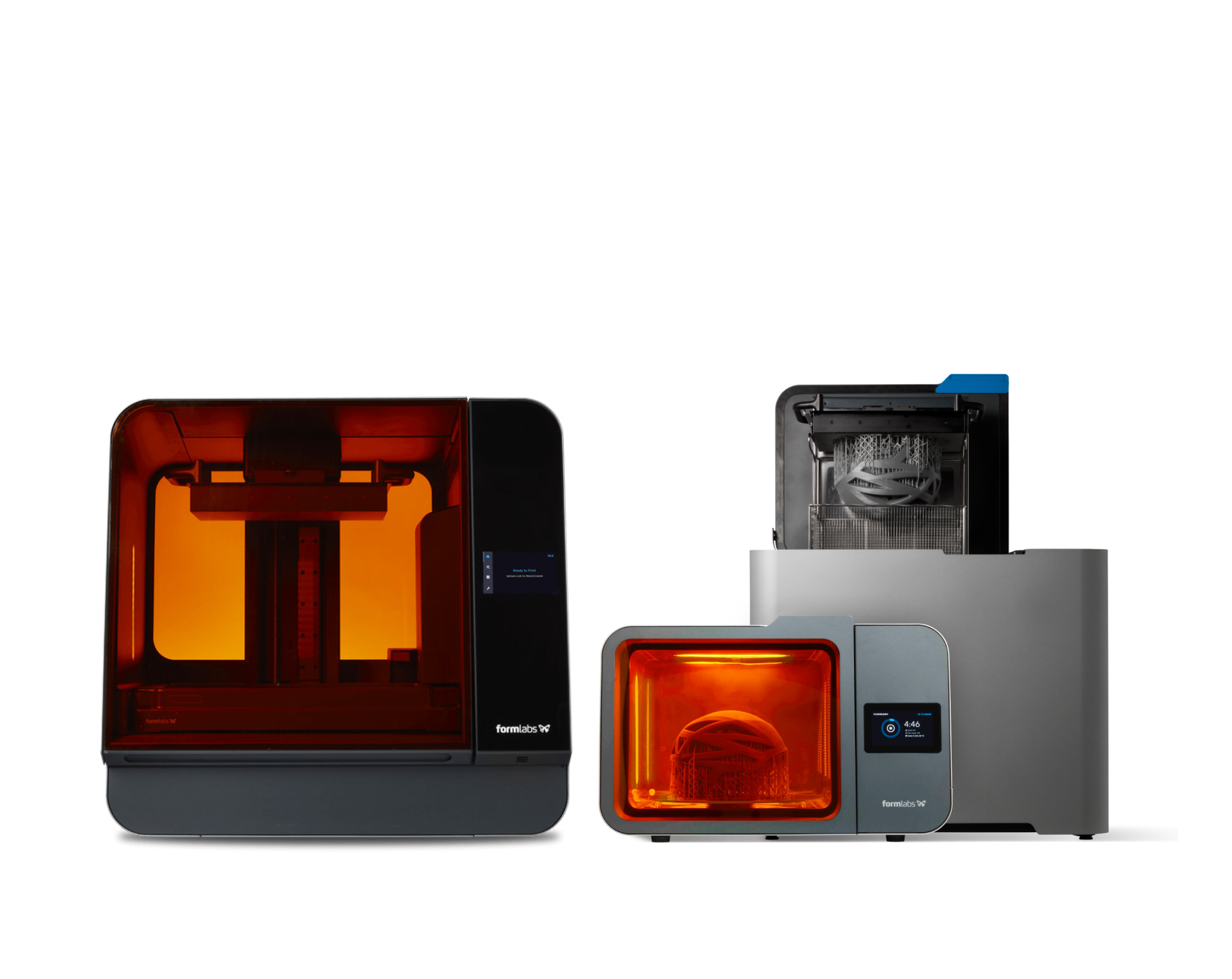

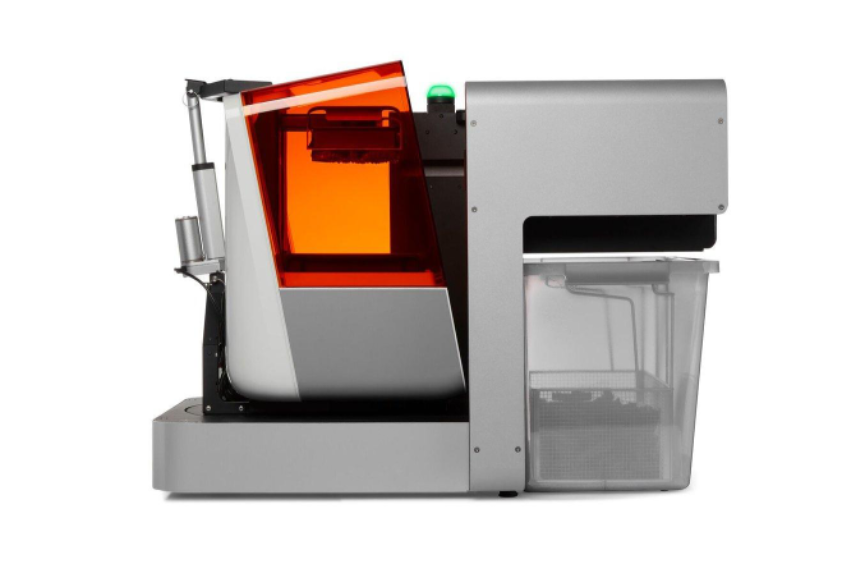

Taiwan TeamA Tech. Co., Ltd.

製品の説明 :

Form 3L為 Formlabs 推出的大型光固化3D列印機,是一款成型空間達擁有達33.5*20*30cm的桌面級3D列印機,讓您的想像力不受限!採用最新專利研發的低應力光固化成型技術(LFS),擁有彈性樹脂槽與封閉式光學模組(LPU)等,大幅增加了機器的可靠與穩定性,精確度、平滑度及透度都大大增加,讓您的大物件也擁有精緻細節!搭配Form Wash L自動清洗機與Form Cure L溫控光固機,以磁力迴旋可一次清洗一個Form 3L平台或是兩個Form 3平台,並使用兩個500W加熱器與大功率紫外線燈全方位高度強化,發揮材料最佳性能!

Form 3L特色包含

1. 33.5*20*30cm 超大列印空間

2. 大型物件也有大大的細緻度

3. 彈性成型槽印大型實心物件也不怕

4. 專利LFS技術配合光學模組使透度平滑度大幅提升

5. 雙卡匣智能給料,安心列印不中斷

6. 高達20多種樹脂滿足外觀、功能驗證需求

7. 輕觸支撐材,好拆不麻煩

8. 繁體中文切片軟體PreForm超好用

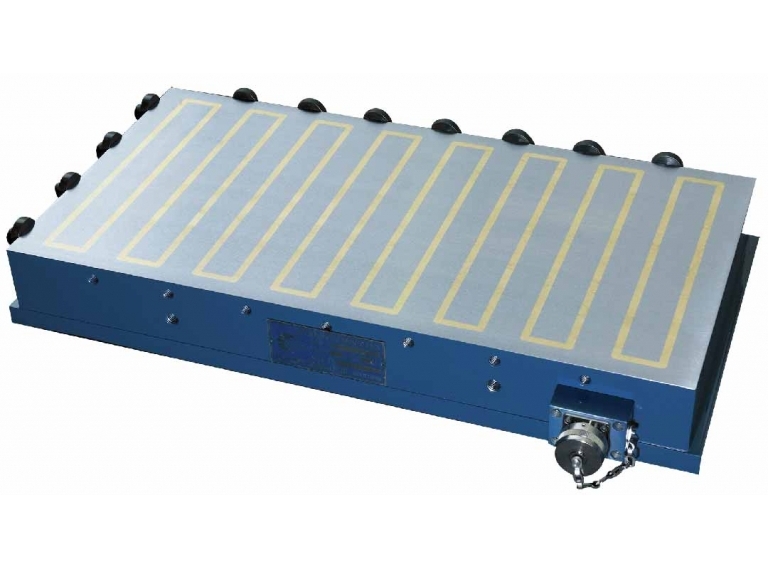

TAI CHONG CO., LTD.

製品の説明 :

用途: CNC切削中心機,銑床,龍門銑床,電腦銑床等切削作業。<br />

特性:<br />

本體與面板一體成型加工完成。<br />

以電控操作,快速充脫磁場變換。<br />

以永久磁鐵吸著工件,沒有停電的危險性。<br />

吸磁作業面,螺栓孔可應用於模具及固定方式的變化。<br />

可配合彈性導磁塊,針對變形平面,作平面加工,大量節省調整時間,提高工作效率。<br />

結構剛性佳,配合精度穩定,適合高精度加工作業。<br />

與強力型電磁鐵比較,大幅度節省電力消耗。<br />

防水效果最確實,保證不漏水,不漏電。<br />

平均吸磁力18kgf/cm2以上。

CLAMPTEK ENTERPRISE CO., LTD.

製品の説明 :

Clamptek’s CLKA series is using the optimal designation, so the clamping capacity is higher than other cylinders. The cylinder body and the fulcrum are integrated structured. Therefore, the cylinder’s size is smaller and it’s more solid and firm.

Clamptek’s CLKA series uses special dust seals to ensure the high dust proof and high sealing performance. As for the lower flange part, which uses minimized designation, it’s suitable for the compact and light fixture.

If you have any customized requests, please feel free to contact us.

Please kindly check the suggested operating pressure as below,

Max. operating pressure: 70 kgf/cm2

Min. operating pressure: 10 kgf/cm2

Taiwan TeamA Tech. Co., Ltd.

製品の説明 :

擺脫時間、地點的限制,利用自動化生產解決方案再創生產率新高!無需人工操作,24小時不停機生產,製造大量、高質量物件,使用 Formlabs 自動化解決方案(包含 Form Auto、群機管理和高容量樹脂系統),在 3D 列印工作流程中更高效的工作並重新定義生產能力。在不增加列印機管理複雜性的情況下擴展您的零件生產。從任何地方點擊發送,Formlabs 自動化解決方案將處理剩下的工作流程。

【最大程度地降低每個零件的成本,節省高達 80% 的勞動力】

在 Form Auto 出現之前,每個完成的零件都需要在後處理之前從成型平台上手動移除。Form Auto 透過將 Formlabs 獲得專利的「快速剝離技術」與「成型平台 V2 」結合使用,完全自動化地移除零件。蒐集的零件被放置在防紫外線的容器中,無縫批量轉移到 Form Wash。

【24 小時不間斷 3D 列印,無需額外程序】

Form Auto 自動化生產系統旨在不閒置列印機、不讓列印物件在序列中等待,無論現場是否有操作人雃,Form Auto 始終準備好開始下一次列印。 隨時隨地構建多列印機群,從辦公室點擊「列印」,立即在生產間開始生產。透過群機管理中的圖像和影片遠程監控和審查成品零件,設備內相機在完成時捕獲每個列印件來保存每個部分的記錄。