展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

HC FENG CO., LTD.

製品の説明 :

FOODIE (Chip/Sludge Removal Machine) works for :

Filtration/Removal of excess components

Chip/Sludge Removal

Fine Chip Removal

No downtime

No consumables

Backwater automatically & simultaneously

Air pressure drive w/o a plug

Vertically fast filter drying up to 90% efficiency

Precision filters effective up 20% for super filtration micro-fines

Easy to move

Filter accuracy can be adjusted

Extend cutting fluid life

LEADWELL CNC MACHINES MFG., CORP.

製品の説明 :

LTC-35LY is a high-performance CNC lathe, suitable for machining various complex parts, especially parts for the automotive industry. It has the following advantages:

The bed structure is very rigid and able to withstand large cutting forces. The spindle and servo motor are high-speed and high-precision, able to quickly and accurately complete the cutting and drilling actions. The Y-axis function allows it to add another moving direction perpendicular to the spindle, in addition to the X-axis and Z-axis, which enables it to achieve more machining angles and shapes, improving the

flexibility and accuracy of machining. The CNC system supports various CNC programs, making it easy for users to design and operate according to different workpieces, reducing errors and waste. It has excellent performance and can improve the quality and efficiency of products, reduce costs and time, and bring more value and competitiveness to users.

Max. swing: 800mm

Max. turning diameter: 430mm

Max. turning length: 1530mm

Bar capacity: 115mm

X-axis travel: 215+25mm

Z-axis travel: 1600mm

Y-axis travel: +100/-80mm

Spindle speed: 2000rpm

Spindle nose: A2-11

Chuck size: 15"

Number of tool stations: 12T

MING YANG MACHINERY CO., LTD.

製品の説明 :

Twin spindle configuration allows for both front and back machining.

Equipped with Sauter Turret

•C-axis functionality on both main and sub-spindle.

•Y-axis functionality promotes side and face milling, drilling, and tapping.

•12-station live turret ensures efficient milling, drilling, and tapping.

•A2-5 spindle nose.

6000rpm high speed spindle.

•High precision spindle accommodates collect chucks and 3-jaw chucks.

•X, Z, Y-axis feed rates: 24/24/10 M/min

MANFORD MACHINERY CO., LTD.

製品の説明 :

With linear guideways on X and Z axes and 30M/Min rapid traverse, SBL series is absolutely an ideal solution for high-speed turning applications.

Features

● 30゚slant bed structure.

● Meehanite cast iron for all structural parts.

● Hardened and ground ballscrews for precise traversing and consistent machining accuracy.

● Fully enclosed splash guard ensures a safe and clean working environment for operators.

MING YANG MACHINERY CO., LTD.

製品の説明 :

This multi-tasking turning center is an advanced machine designed for precision complex parts processed in one setup.

Power & Versatility: It has Double Spindles and Turrets with back machining provided by an 8-station sub-turret and sub-spindle with a total tool capacity of up to 32 tools. This solution is a powerful combination of power, precision and versatility.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: VDI 25 8-Stations Sub-Turret, 3.7/5.5 kW Spindle Power, 48 mm Through Hole.

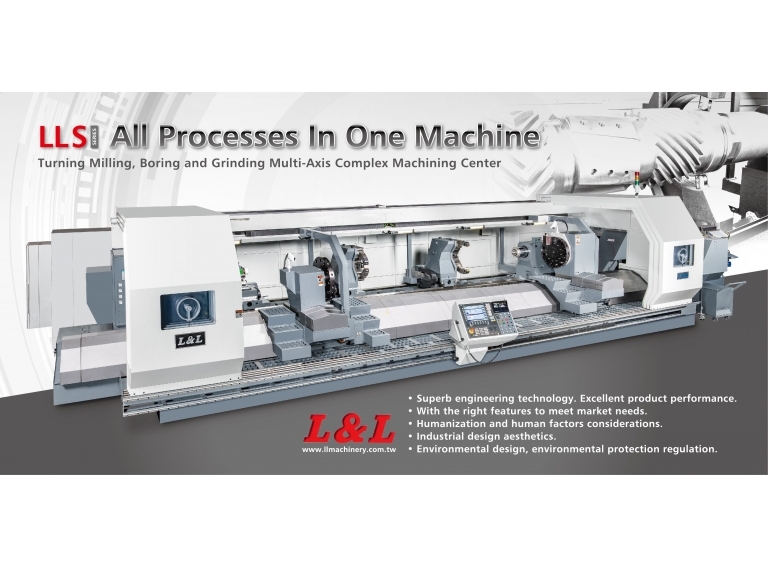

L & L MACHINERY INDUSTRY CO., LTD.

製品の説明 :

L&L LLS multi-axis composite cutting center machine, targeting the plastic rubber machinery industry, the application function exceeds customer demand:

a. Reduce the number of times of machining twice, reduce tool interference, and reduce work time by 50%.

b. Bed structure patent, one-piece casting, μ-level scraping process to ensure accuracy and stability.

c. Programmable tailstock, hydraulic center frame, independent chip removal device, programmable automatic door, high speed splash screen, full cover sheet metal design.

d. Full-cover design reduces the leakage of coolant, the design of the coolant collect plate for bed base, and the addition design of oil mist collector to reduce oil and gas pollution.

TAIWAN MACHINE TOOL CO., LTD.

製品の説明 :

Strong casting and the perfect boxway stucture provides excellent cutting capacity for TTB-20MW Series. Sub-spinfle with milling function and Y-axis can satisfy customers' miltiple needs.

-The one cast base incorporates FEM analysis to achieve its optimal ribbing and structure to further enhance machine rigidity and stability.

-The 30 degree slant bed design has low center of gravity for easier swarf management and better erogonomic design. The TTB-20MW Series also offer optional rear type chip conveyor.

-To make sure the usage life of Y-axis ballscrew will get longer, there are three bearing on Y-axis ballscrew to enhance the support for pressure from top.

-The TTB-20MW Series can achieve maximum 20m/min for X axis and 25m/min for X axis. And the servo motors adopt absolute encoders for faster and more reliable positioning.

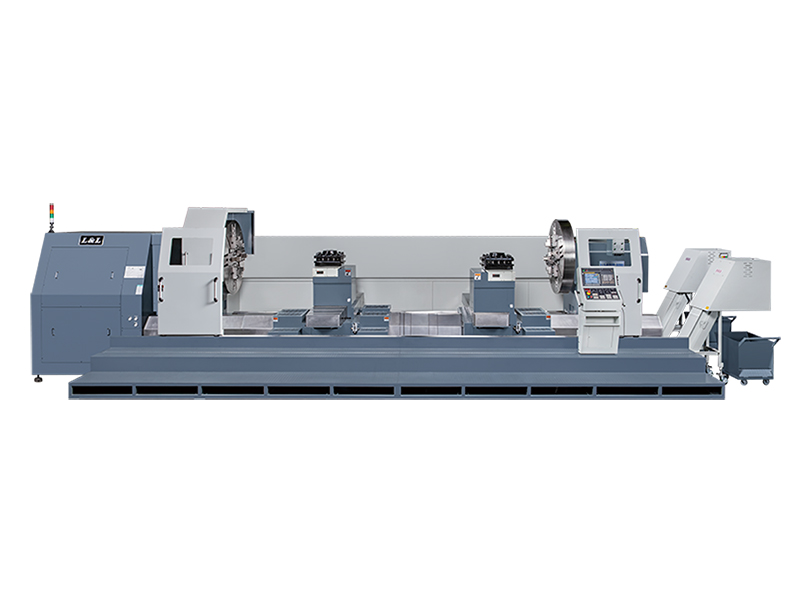

L & L MACHINERY INDUSTRY CO., LTD.

製品の説明 :

Smart heavy-duty multi-axis composite cutting machine, LLS-M, for the target industry market (oil industry, aerospace industry, steel industry and rubber and rubber industry), achieved ALL Processes In One Machine to reduce the clamping and shortening process, with precision and life management The intelligent machine, constructing the machine information management platform and man-machine management interface, integrating the computer numerical controller, the smart set-top box and the cloud product life cycle database, providing relevant data and data through artificial intelligence calculation analysis and application, reaching the machine Accuracy and life and performance improvement, and applied to the virtual reality pre-sales service system, the use of the real-life expansion after-sales service system to build a smart mechanical value service chain.