展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

FUI JET TECH CO., LTD

製品の説明 :

The zero-point positioning system is a normal clamping mechanism, which is opened during ventilation and the air pressure is cut off. When the zero-point positioning system is ventilated, the pressure will pass through the compressed spring inside the piston, causing the piston to rise, and the steel balls can retreat toward the water pump. When the air source is turned off, the spring will push back the piston, and the piston handle will The steel ball is pushed toward the middle, causing the ladder bolt to

CHIAH CHYUN MACHINERY CO., LTD.

製品の説明 :

■No matter what operation – turning, milling, drilling, tapping, cutting, side turning and back machining, the

CB series does it all in one operation.

■Sliding head without a guide bush design provide faster setups, lesser remnants, and more cost reduction.

■The CB series provide multiple tooling systems is suitable for versatile cutting applications. On the front side

tooling system, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools. Moreover, on the back milling

system, user can set 4 live tools. The maximum tool speed is 6000 rpm. User can install O.D. and I.D. tools

on the back milling system.

■The sub-spindle head moves on the precision roller type linear ways with extra-large span design for

outstanding stability and positioning accuracy.

MING YANG MACHINERY CO., LTD.

製品の説明 :

This multi-tasking turning center is an advanced machine designed for precision complex parts processed in one setup.

Power & Versatility: It has Double Spindles and Turrets with back machining provided by an 8-station sub-turret and sub-spindle with a total tool capacity of up to 32 tools. This solution is a powerful combination of power, precision and versatility.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: VDI 25 8-Stations Sub-Turret, 3.7/5.5 kW Spindle Power, 48 mm Through Hole.

ECHAINTOOL PRECISION CO., LTD.

製品の説明 :

"ECHAINTOOL is a well-known leading brand in Taiwan. It is the leading manufacturer of professional cutting tools and cooperates with the world's leading brands of cutting tools. It has multiple cutting tool products and sufficient inventory to meet the different needs of customers. The quality products are all made in Taiwan, and have won the ""Taiwan Excellence Award"" and ""Excellent Design Award"" and passed the IS0 9001 certification, which is directly recognized by many customers from the world of aerospace, automotive and mold companies.

Adhere to the promotion of our own brand ""ECHAIN"", mainly develop and manufacture all kinds of discarded cutting tools (carbide end mills, inner/outer boring tool holder, threading tool, various milling cutters, drilling tool, hole boring cutter, rapid drills, etc.) and related components are widely used in CNC lathes and milling machines for various precision machines.

The carbide end mills developed by the ECHAIN team are all produced by the German WALTER five-axis machine to obtain the best quality and effectively meet the needs of the industry. "

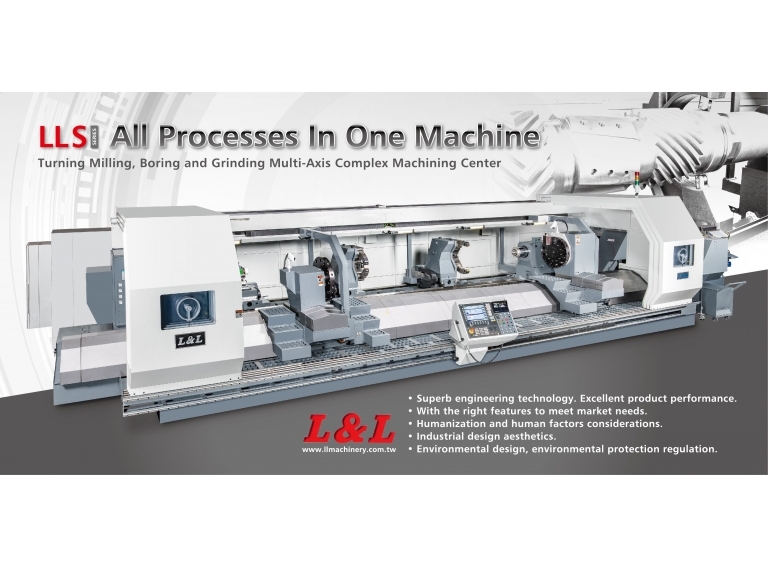

L & L MACHINERY INDUSTRY CO., LTD.

製品の説明 :

L&L LLS multi-axis composite cutting center machine, targeting the plastic rubber machinery industry, the application function exceeds customer demand:

a. Reduce the number of times of machining twice, reduce tool interference, and reduce work time by 50%.

b. Bed structure patent, one-piece casting, μ-level scraping process to ensure accuracy and stability.

c. Programmable tailstock, hydraulic center frame, independent chip removal device, programmable automatic door, high speed splash screen, full cover sheet metal design.

d. Full-cover design reduces the leakage of coolant, the design of the coolant collect plate for bed base, and the addition design of oil mist collector to reduce oil and gas pollution.