展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

FOCUS CNC CO., LTD.

製品の説明 :

FNL-220 series turn-mill machine is integrated with innovative feature 30-degree slant bed, roller type linear guideways and 60-degree compound Y axis. Roller type linear guideways ensure high accuracy performance during high speed machining and provide 30% stronger rigidity than ball type guideways. With the biggest Y axis travel ±55mm in same class, high torque live tooling and full C axis for main and sub-spindle.

OWNNER INDUSTRIAL CO., LTD.

製品の説明 :

Standard Gang-type or Turret(optional). Gang-type permits quick tool change. Gang-type tool system can make tools change faster. Increase the external oil tank and lengthen the oil temperature cooling time.The oil temperature natural cooling principle is adopted to make the processing oil temperature more stable.

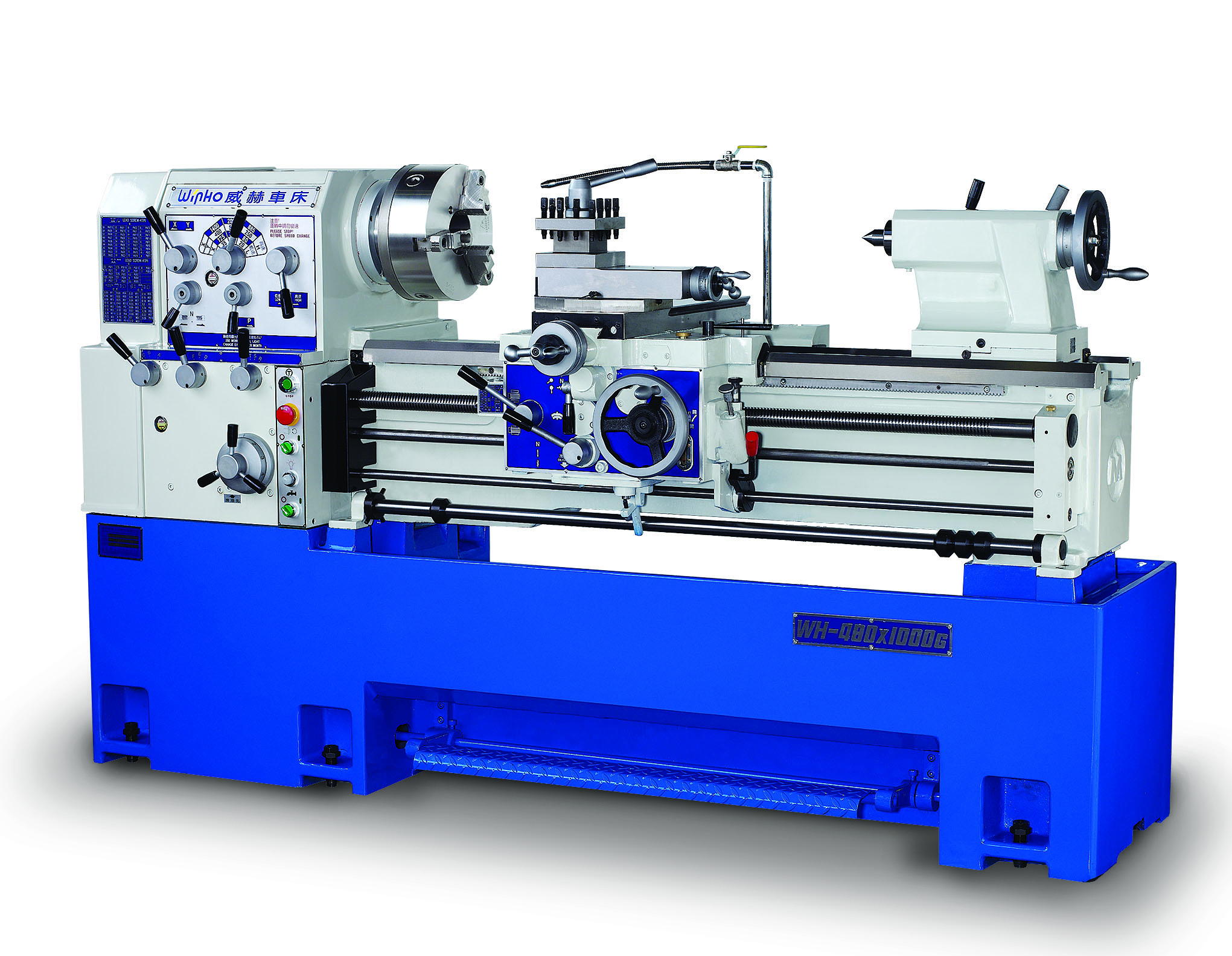

WIN HO TECHNOLOGY INDUSTRIAL CO., LTD.

製品の説明 :

High Speed Precision Lathe

1. Selective bed width:

S series: 300mm.

M series: 350mm.

L series: 400mm.

2. Varied spindle bore diameters:

S series: O58mm / O80mm (Option).

M series: O85mm / O105mm (Option).

L series: O85mm / O120mm (Option).

3. With FAG or SKF precision bearings installed on

spindle, maximum cutting depth can be 8mm on

50mm diameter and best roundness 0.003mm

(200mm long).

4. Equipped with plastic rear gears, shafts and

gears inside headstock are well protected if crash

should occur (S430 & S480 Series).

5. Thermal treated and precision ground alloy

gears.

6. Universal gearbox for both imperial and metric

thread-conversion table also attached.

7. Tracks of cross slide and bed are well lubricated

with lubrication pump (manual).

8. Overload device to ensure safety when

operating.

9. Wear-resistant phosphor bronze lead screw

nuts.

10. Durable reservoir oil bath type cross slide (for S

series).

11. Thermal treated Meehanite bed casting.

12. One-piece base for high rigidity and low

vibration.

13. High-capacity coolant tank offers sufficient

coolant output.

14. All series certified for CE.

Reservoir Oil Bath Type Cross Slide

JARNG YEONG ENTERPRISE CO., LTD.

製品の説明 :

This model can work with two axes gantry loader to transform CNC lathe be automation which is in order to accomplish automatic catching single blank material, uploading, unloading and clamping manufacture progress to increase physical labor productivity.

The most advantage is we can stand on the customer’s machining demand to choose the different types of feed stations.

CHIAH CHYUN MACHINERY CO., LTD.

製品の説明 :

SY2-42 Swiss-type CNC Lathe

■ SY2-42E has Ø42mm maximum bar feeding dia. and provide the option to go with or without a guide bush to achieve optimum machining condition.

■ Main spindle tool system can install 6 radial live tools, 3 axial live tools, 6 O.D. tools, 5 I.D. tools.

■ Sub Spindle tool system can install 8 ER-20 live tools, combines with the Y2 linear axis and C2 rotating axis to perform the more complex turning and milling process.

YING HAN TECHNOLOGY CO., LTD.

製品の説明 :

YTL8320G

CNC computer lathe and portal robot arm

Machine features

- Automated process control

- Mass production of extremely precise workpieces

- Visual programming made easy

- Efficient process intelligence

Machine specifications

- 8-inch spindle chuck

- 45 degree slant back bed

- Z/X axis travel: 320/185mm

- Max. load of robotic arm is 4kg

- 10 station of storage capacity

CHEN SHIN (TCSM) MC CO., LTD.

製品の説明 :

Oil mist collector:

Totally made in Taiwan with TÜV CE marking.

Customisation Accessories ,Industry 4.0 Accessories and ODM/OEM Services are available.

Welcome for ODM/OEM cooperation.

We are Agent of SCOTTI in Taiwan market.

We are Agent of DUPLOMATIC in Taiwan market.

Electrical Oil Mist Collector

MING YANG MACHINERY CO., LTD.

製品の説明 :

This heavy duty multi-tasking turning center is an advanced and economical solution designed to process precision complex parts with fast cycle times.

Power & Versatility: It has Double Spindles, a BMT 12 station turret and 4 gang tools for economical machining. Coupled with superimposed cutting it’s a powerful solution for precision complex workpieces with extremely fast cycle times.

Front Machining: BMT 45, 12 Stations, Up to 24 Tools, 7.5/11 kW Spindle Power, 55 mm Through Hole

Back Machining: GT42: 4 x 20 mm ID Tools, GT52: 4 x 16 mm ID Tools, Or 3x 20 mm ID Tools, Or 3x 25 mm ID Tools