展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

JARNG YEONG ENTERPRISE CO., LTD.

製品の説明 :

1. This model combined the functions of turning and milling and can provide customers with more working conditions.

2. Optional C-axis for arbitrary angle spindle positioning and contour control

3. Optional Y-axis live tooling device and end live tooling device can be used for inner and outer diameter turning and milling.

4. Optional:Y-axis side milling device (4-shaft, ER-20), and the distance between each shaft reaches 55mm.

MING YANG MACHINERY CO., LTD.

製品の説明 :

This multi-tasking turning center is an advanced machine designed to process precision complex parts in one setup.

Power & Versatility: It has Double Spindles, a VDI/BMT 12 station Turret and a 2nd Y-Axis for back machining with 14 tools for a total capacity of up to 38 tools. This solution with superimposed cutting is a powerful combination of precision and two Y-axes for machining of complex workpieces with extremely fast cycle times.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: Gang Tools Slide: 14 Tools, 3 Cross Live Tools, 3 Face Live Tools, 3 OD & 5 ID Tools.

MING YANG MACHINERY CO., LTD.

製品の説明 :

The model MTY 51/65 is equipped with a dual spindle double turret and double Y axes. The machine is combined with FANUC 31i PLUS for simultaneous control on triple tool systems. The machining support two turrets for one spindle and one turret for two spindles at the same time. In other words, each process will collaborate with three tools. Mostly, the machine improves 50% efficiency.

CHIAH CHYUN MACHINERY CO., LTD.

製品の説明 :

■No matter what operation – turning, milling, drilling, tapping, cutting, side turning and back machining, the

CB series does it all in one operation.

■Sliding head without a guide bush design provide faster setups, lesser remnants, and more cost reduction.

■The CB series provide multiple tooling systems is suitable for versatile cutting applications. On the front side

tooling system, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools. Moreover, on the back milling

system, user can set 4 live tools. The maximum tool speed is 6000 rpm. User can install O.D. and I.D. tools

on the back milling system.

■The sub-spindle head moves on the precision roller type linear ways with extra-large span design for

outstanding stability and positioning accuracy.

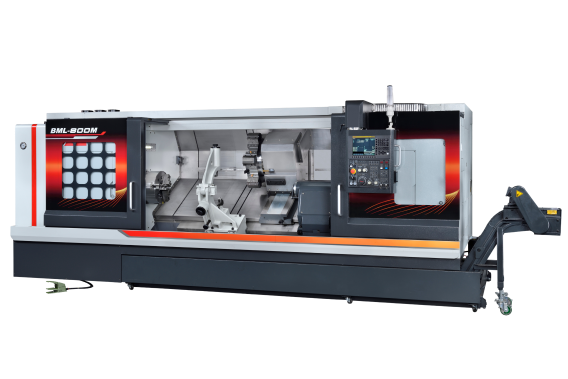

YIDA PRECISION MACHINERY CO., LTD.

製品の説明 :

The (B)ML-800 series is a highly customizable turning center with various options for spindle, gearbox, base, tailstock, turret and multiple selectable feed speeds. It can efficiently handle the most demanding machining requirements.

1. The modular structure design of the base has high strength and rigidity. It is molded as a single unit, effectively absorbing the vibrations generated by the machining and providing the stability and precision required for heavy cutting operations, without any distortion or deformation.

2. The optimal modular design spindle features high speed and power, and can be paired with a high-torque output gearbox design, offering a variety of processing options to meet different machining needs.

3. The robust toll turret design allows for quick and reliable tool changes, ensuring high efficiency and precision. It caters to the characteristics of various cutting processes, effectively enhancing machining capabilities.

3. The high-strength design of the transmission structure ensures precise positioning and greatly enhances machining efficiency and stability.

4. Ergonomically designed interface makes operation easy and maintenance convenient. Sheet metal design incorporates comprehensive safety considerations.

LIS AUTOMATIC CONTROLLED CO., LTD.

製品の説明 :

The PJ-30VT is a frequency control (variable volume) complex system. Supplied for maximum 70bar (1000psi), 100bar (1500psi) or 140bar (2000psi) working pressure to Swiss Lathes, CNC Lathes, and Machining Center. This system carries the LIS Automatic patent high-performance centrifugal filtration device, extended the lifetime of the consumables, and also lets the system more stable. Designed for the restricted tank capacity machine, reduced the problems of the tank foaming and overheat effectively.

OWNNER INDUSTRIAL CO., LTD.

製品の説明 :

Standard Gang-type or Turret(optional). Gang-type permits quick tool change. Gang-type tool system can make tools change faster. Increase the external oil tank and lengthen the oil temperature cooling time.The oil temperature natural cooling principle is adopted to make the processing oil temperature more stable.

SONG GIA INDUSTRIAL CO., LTD.

製品の説明 :

●精密鉸孔神器-浮動鉸刀柄,可解決以下問題:

1. 孔的直線行差

2. 鉸刀不耐用

3. 孔的尺寸擴大,尺寸精度達不到要求

4. 孔的中間大,兩頭小,圓柱度達不到要求

5. 內孔表面粗糙度達不到要求

6. 大批生產時無法保證孔徑尺寸的一致性 。

●浮動鉸刀柄的特點:

1.可透過360度浮動讓鉸刀對準下孔徑,避免對不準而造成擴孔或縮孔

2.徑向振幅抑制在5μm以下

3.提高鉸孔光潔度

4.彌補車床公差,提高鉸孔精密度

5.提高鉸孔的直線度和圓柱度

●浮動鉸刀柄可應用加工機械:鑽床、立式加工中心、研磨機。 可夾持工具:鉸刀、滾光刀

**產品連結→→https://www.songgia.com.tw/tw/products/other-tools/floating-reamer-holder