展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

Compared to resin bond and metal bond wheels, Electroplated Grinding Tools are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity. Besides, these tools are noted for:

1. Allow special shapes and profile tools to be made at short notice.

2. Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Grinding Tools :

1. Internal grinding: Suitable for the internal grinding of carbide and High Speed Steel. The smallest diameter of our electroplating area is 0.3mm so it could be used in drilling for fined ceramics.

2. Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325, good for rough and fine processing.

3. Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. In order to improve work efficiency, we could also combine different grit sizes in the same diamond mounted point.

4. Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel. Bowl-shape wheel with standard specification is also provided, suitable for the grinding of turning tools.

5. Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or trimming aluminum oxide wheel.

6. Gem grinding: shape grinding for gem, semi-precious stones, shell and jade.

7-LEADERS CORP.

製品の説明 :

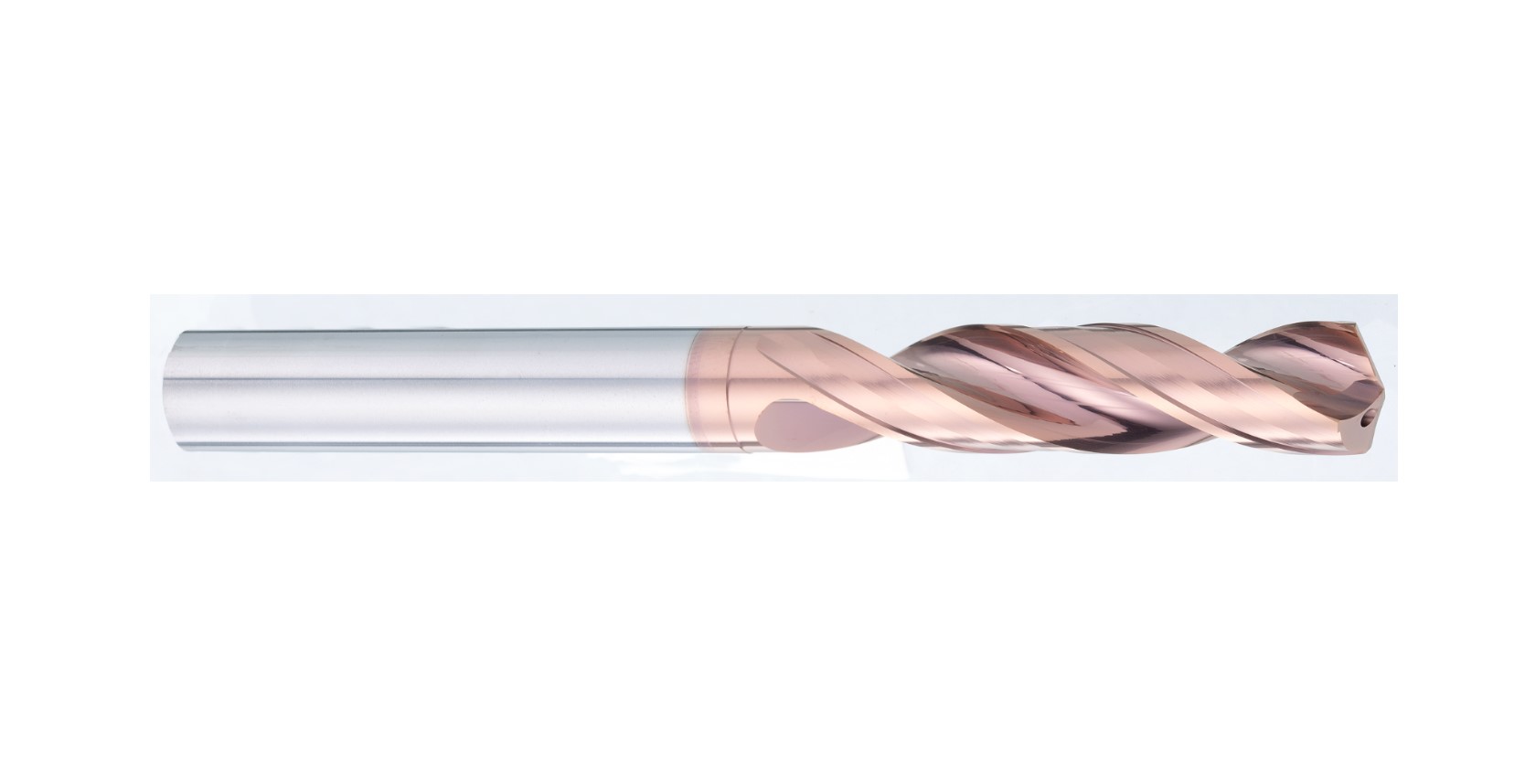

JIS 3XD Drills with Oil-Feed

140° S-shape drill tip design to reduce axial force.

Design with groove shape to provide higher chip removal rates.

Good wear resistance and lubrication with Nano multilayer coating.

Oil-feed design could reduce temperature effectively and increase chip removal rates during cutting process.

Application for drilling with Steels which under HRC48, Cast Iron…etc.

Suitable for drilling with 3XD depth.

DEEP JET INDUSTRY CO., LTD.

製品の説明 :

1.Special cutting-edge design with low resistance to reach better chip-off from the groove. This shows the tool's stability in high speed machining.

2.The special coating enhances the anti-oxidation and wear resistance to increase high speed performance.

◆Carbide Drills With Internal Coolant Holes:

Internal coolant holes can highly increase the performance of cooling and chip removal rate.

◆Carbide Flat Drills:

Good for curve and inclined surface machinning.

CHIN MING PRECISION TOOLS CO., LTD.

製品の説明 :

For Ultra-Hard Material Machining

(For Carbide, SiC, Al2O3, Si3N4 and ZrO2 Machining.)

------------------------------------------------------------

PCD Helix Flute End Mills- Multi-Flute:

★ Multi-flute decreases cutting resistance and makes high efficiency.

★ Applies to high precision machining of carbide and ceramics.

PCD Helix Flute Drilling:

★ For carbide, ceramics, aluminum, copper, graphite and carbon fiber drilling.

PCD Ball Rolling Cutter:

★ Special cutting edge and high accuracy R of ±0.005mm realize high quality mirror polished machining.

★ Applies to carbide and hardened steel(≦70HRC) mirror polished machining.

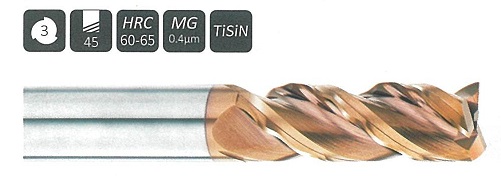

PCBN Helix Flute End Mills:

★ For hardened steel(HRC45~65°) and powder metallurgy machining.