展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

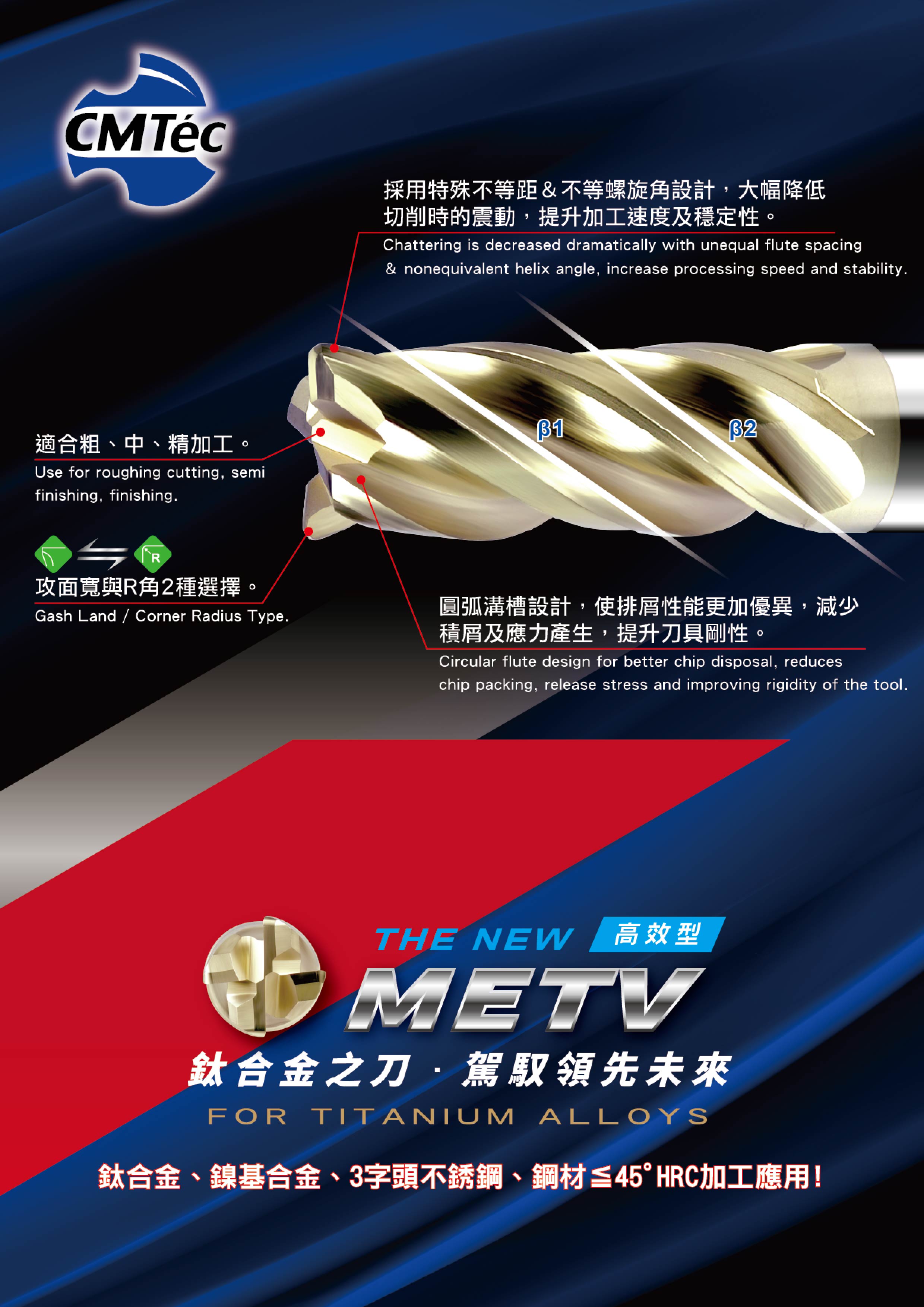

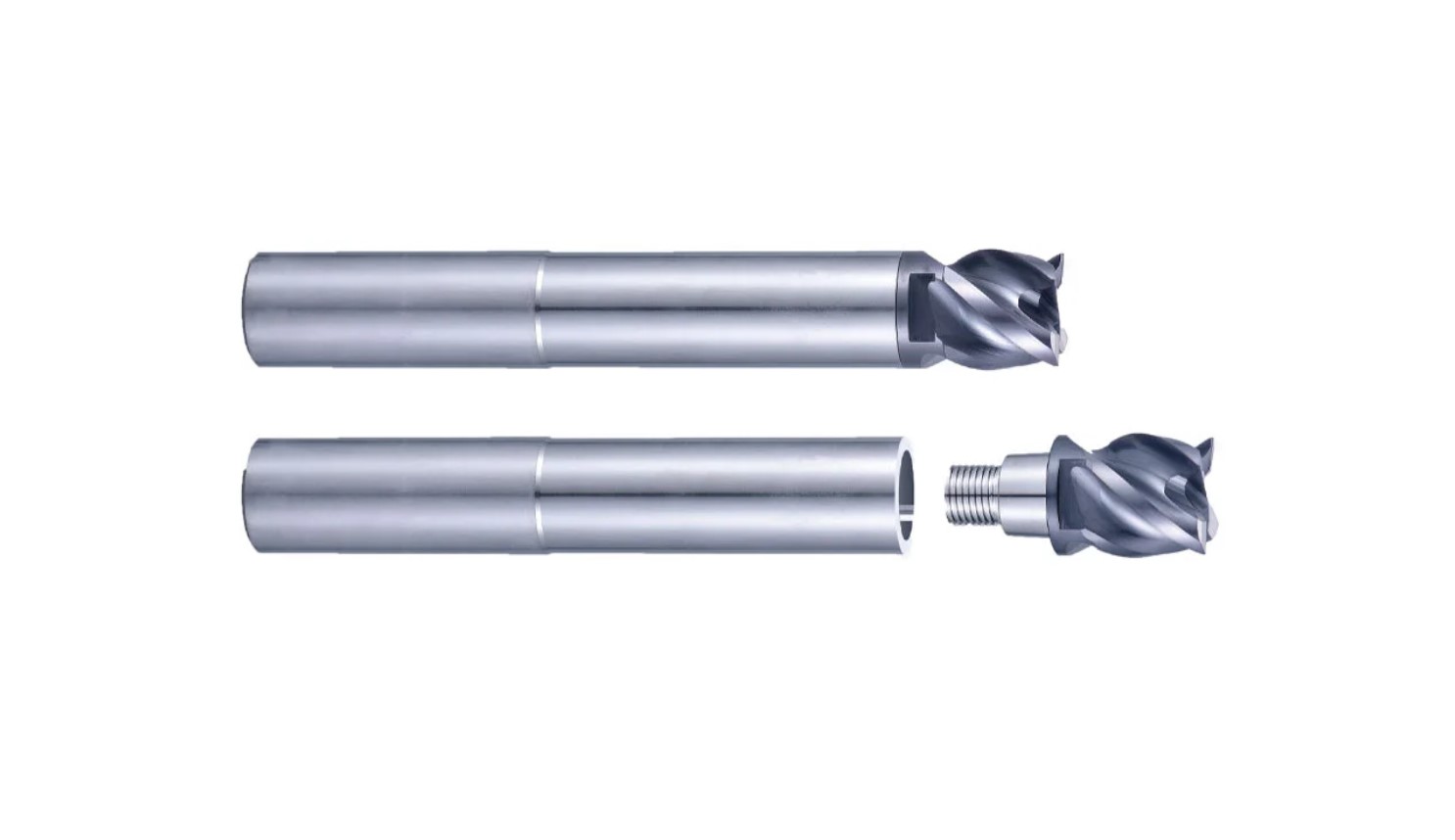

CHIN MING PRECISION TOOLS CO., LTD.

製品の説明 :

★ For titanium alloy, stainless steel and alloy steel(≦45°HRC) machining.

★ Chattering is decreased dramatically with unequal flute spacing & nonequivalent helix angle, increase processing speed and stability.

★ Circular flute design for better chip disposal, reduces chip packing, release stress and improving rigidity of the tool.

★ Use for roughing cutting, semi finishing, finishing.

MAROX TOOLS INDUSTRIAL CO., LTD.

製品の説明 :

【External Turning Tools with coolant】

AACLN、AATJN、AATQN、AAWLN、ADCLN、ADDJN、ADDQN、ADTEN、ADTJN、ADTQN、ADVJN、ADWLN、AMCLN、AMDJN、AMTJN、AMVJN、APCLN、ASCLC、ASDNC、ASDJC、ASTUP、ASVJB、ASVJC、ASVJP、ASVKB、ASVKC、ATJNR、AWLNR

【Boring Bar with coolant】

L-SCLC-V、L-SDUC-V、L-STLC-V、L-STUP-V

【Threading Tools with coolant】

ASER、ASER-WP、ASER-NA

【Grooving holder with coolant】

ACGWS、AEVSC/M、ADGT、AGHR、AGNDMR、AGHSR、AGWC、AKGD、ASLAL-38、ATGTR、ATSE、ATTE、AWGCSM、AUASR、AUSR

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

HON JAN CUTTING TOOLS CO., LTD.

製品の説明 :

Heat-treated steel

Coolant design

Perfect 90° milling

High number of teeth, increased productivity

PTN10-cutting depth up to 5mm

PTN16-cutting depth up to 10mm

PTN16-the clamping screw is enlarged for easier locking and greatly improved stability

The unique design of low cutting resistance can better machining continuity, achieve milling of 90°, and get a perfect machining surface.

7-LEADERS CORP.

製品の説明 :

Multipurpose End Mills with Corner Radius- 4 Flutes

Using UMG carbide material enable to enhance lubrication and wear resistance.

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Cutting edge with corner radius design and nano multilayer coating AlCrN are suitable for carbon steel, alloy steel and stainless steel with impurities and sticky materials.

Suitable for various kinds of work materials from the end of roughing to finishing.

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

Compared to resin bond and metal bond wheels, Electroplated Grinding Tools are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity. Besides, these tools are noted for:

1. Allow special shapes and profile tools to be made at short notice.

2. Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Grinding Tools :

1. Internal grinding: Suitable for the internal grinding of carbide and High Speed Steel. The smallest diameter of our electroplating area is 0.3mm so it could be used in drilling for fined ceramics.

2. Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325, good for rough and fine processing.

3. Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. In order to improve work efficiency, we could also combine different grit sizes in the same diamond mounted point.

4. Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel. Bowl-shape wheel with standard specification is also provided, suitable for the grinding of turning tools.

5. Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or trimming aluminum oxide wheel.

6. Gem grinding: shape grinding for gem, semi-precious stones, shell and jade.

Fey Che Trading Co., LTD.

製品の説明 :

MUGEN COATING PREMIUM Plus具有高抗氧化性和耐磨性,適用於 60HCR 以上的加工。即使在 45~60HRC的加工中也能表現出與 MUGEN COATING PREMIUM 相同的性能。____________________________________________________________

[ 方 頭 銑 刀 ]

[ 型號 : MHDSH445・MHDSH645 ]

*刃長有2D與3D型式可供選擇

*採用最新開發之白金級PLUS無限鍍膜,最適合加工45~70HRC之高硬度鋼材

*高剛性設計實現高精度加工____________________________________________________________

[ 球 頭 立 銑 刀 ]

[ 型號 : MSBSH330-5X ]

*採用耐崩損性佳的新素材及銳角刃口設計,可以減輕切削抵抗

*採用不等分割設計,可以防止震刀

*5軸機專用圓球立銑刀

[ 型號 : MRBSH330 ]

*最優化中心刃形狀、 能進行高切削深的高效率

*加工即使在45〜70HRC高硬度鋼,兼具切削性與

*耐磨耗性,能實現長壽命、高效率的加工

[ 型號 : MRBSH230SF ]

*加工70HRC的高硬度鋼材,也能實現長壽命及穩定的加工性能

*採用耐崩損的新素材及減低切削抵抗的刃口設計____________________________________________________________

[ 端 角 R 立 銑 刀 ]

[ 型號 : MHRSH430RSF ]

*全新的修光刃設計可提升平面加工表面品質

*R角無段差設計,提升側面加工表面品質

*高剛性設計實現高精度加工

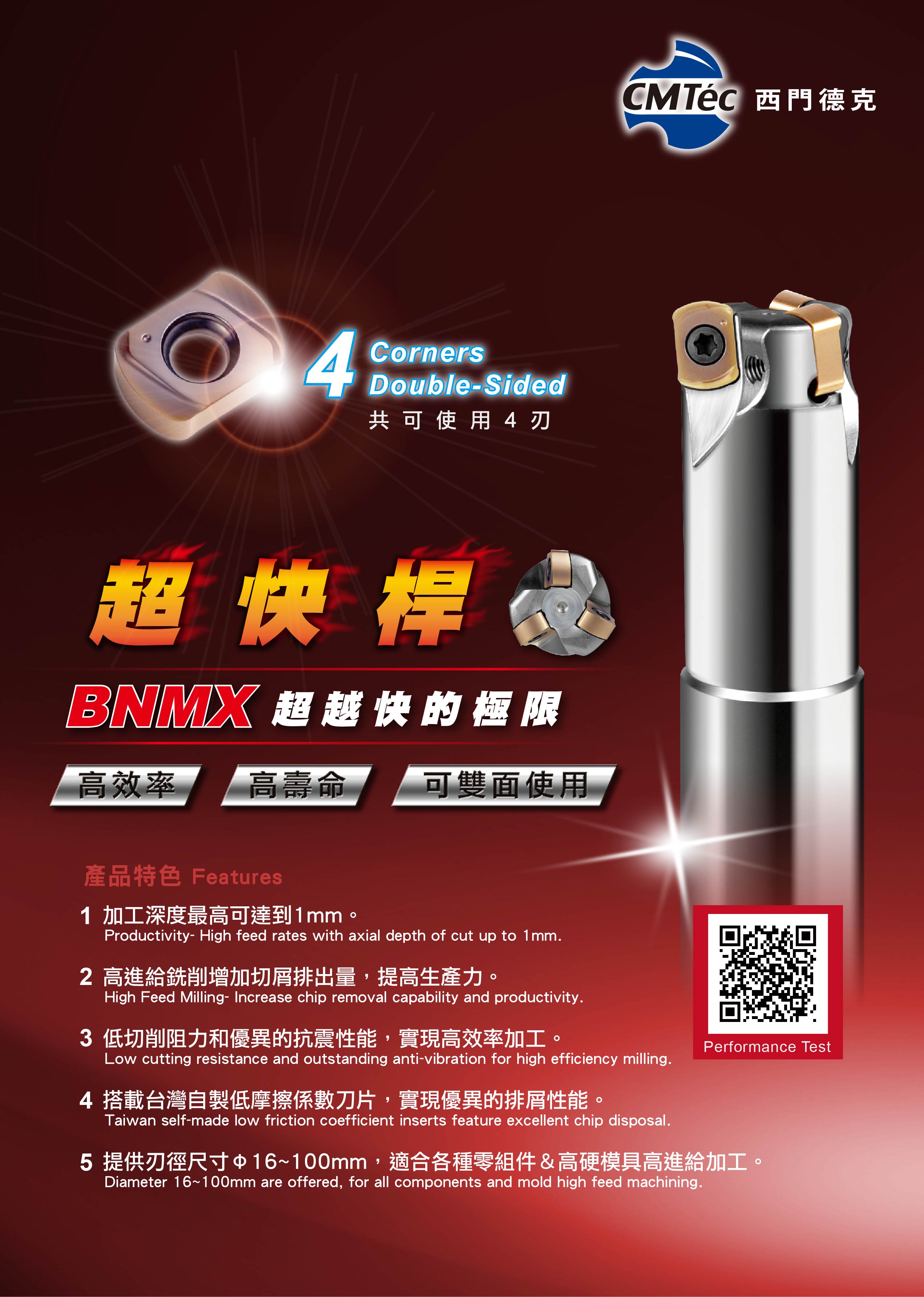

CHIN MING PRECISION TOOLS CO., LTD.

製品の説明 :

★ Productivity- High feed rates with axial depth of cut up to 1mm.

★ High Feed Milling- Increase chip removal capability and productivity.

★ Low cutting resistance and outstanding anti-vibration for high efficiency milling.

★ Taiwan self-made low friction coefficient inserts feature excellent chip disposal.

★ Diameter 16~100mm are offered, for all components and mold high feed machining.