展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

This is a revolutionary new concept of engraving tools with indexable carbide inserts. They offer you the ability to produce HIGH QUALITY ENGRAVING in most materials.

The latest coated carbide grades help you to obtain higher speed and feed rate, dramatically reducing your cycle time.

● High Positive Rake Angle

• Indexable insert.

• Suitable for engraving all types of materials, such as plastic, non-ferrous metal, aluminum, copper, carbon steel and stainless steel.

● Multi-Side Grinding

• Full peripherally ground insert to ensure efficient repeatability.

• It performs excellently without producing any burrs, especially in copper, aluminum and stainless steel.

● High Speed, High Feed Rate

• Designed to run at high speed, up to 40,000 r.p.m.

• Feed rate 0.08mm (0.003”) / rev. apply to aluminum; 0.05mm (0.002”) / rev. apply to stainless steel.

• Reduces engraving cycle time!

● Economical

• Each indexable insert has 2 cutting edges.

• No resharpening required. Tool length is unchanged.

• No need to reset after changing insert or cutting edge.

• Excellent repeatability!

7-LEADERS CORP.

製品の説明 :

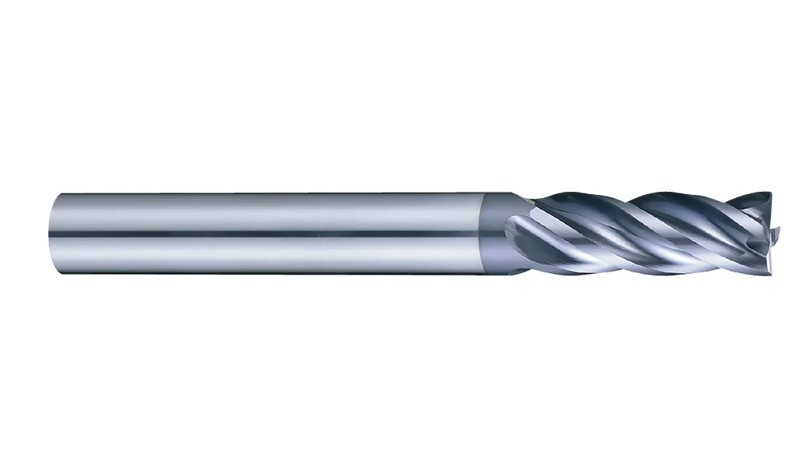

Multipurpose End Mills- 4 Flutes

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Obviously improve tool life with Nano multilayer coating AlTiCrN.

Suitable for different kinds of materials cutting.

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

NC Helix Drill cuts material by helical interpolation; serrated cutting edge minimizes chip length.

Low spindle power is not a problem, good for drilling material that generates long, soft chips.

● Reduce Your Tool Inventory

Each holder can machine di erent diameters and hole depths, saving your tool inventory and cost!

No need to peck drill or dwell in operation even machine without internal coolant.

● Lower spindle power consumption Easy to cut!

• Thanks to the small cutting load of the serrated cutting edge and helical interpolation lower power consumption. Work quicker, smarter and achieve better results.

• Circular ramping milling, maximum ramping angle is 20°. For example: tool HD27 machining Ø50 mm hole, 9 mm pitch for aluminum, 6 mm pitch for carbon steel.

● Special insert geometry - exceptional swarfs control.

• Serrated cutting edge makes the chips short and small, and easier to evacuate.

• Eliminate swarf and vibration problems while drilling di cult material or deeper holes.

● “One tool” performs multiple applications

• Not only a drill, but an end mill too.

• Small radius path to cut a hole or step hole, various curved cavity shapes on di erent materials.

VISION WIDE TECH CO., LTD.

製品の説明 :

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively, and to extend tool lifetime and offer the best choice for composite angle machining. GSF Series had excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

•Continuous 2-axis head

•5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

•Built-in Spindle Direct-Driven on B&C axis, 12,000~24,000rpm spindle speed.

•Backlashless driving on B/C axis,Rotation Positioning accuracy ±5”.

•Low table height, closer operating zone, wider door width are convenient design for user.

•Chain type chip conveyor (standard) is able to remove iron chips efficiently.

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

Compared to resin bond and metal bond wheels, Electroplated Grinding Tools are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity. Besides, these tools are noted for:

1. Allow special shapes and profile tools to be made at short notice.

2. Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Grinding Tools :

1. Internal grinding: Suitable for the internal grinding of carbide and High Speed Steel. The smallest diameter of our electroplating area is 0.3mm so it could be used in drilling for fined ceramics.

2. Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325, good for rough and fine processing.

3. Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. In order to improve work efficiency, we could also combine different grit sizes in the same diamond mounted point.

4. Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel. Bowl-shape wheel with standard specification is also provided, suitable for the grinding of turning tools.

5. Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or trimming aluminum oxide wheel.

6. Gem grinding: shape grinding for gem, semi-precious stones, shell and jade.

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

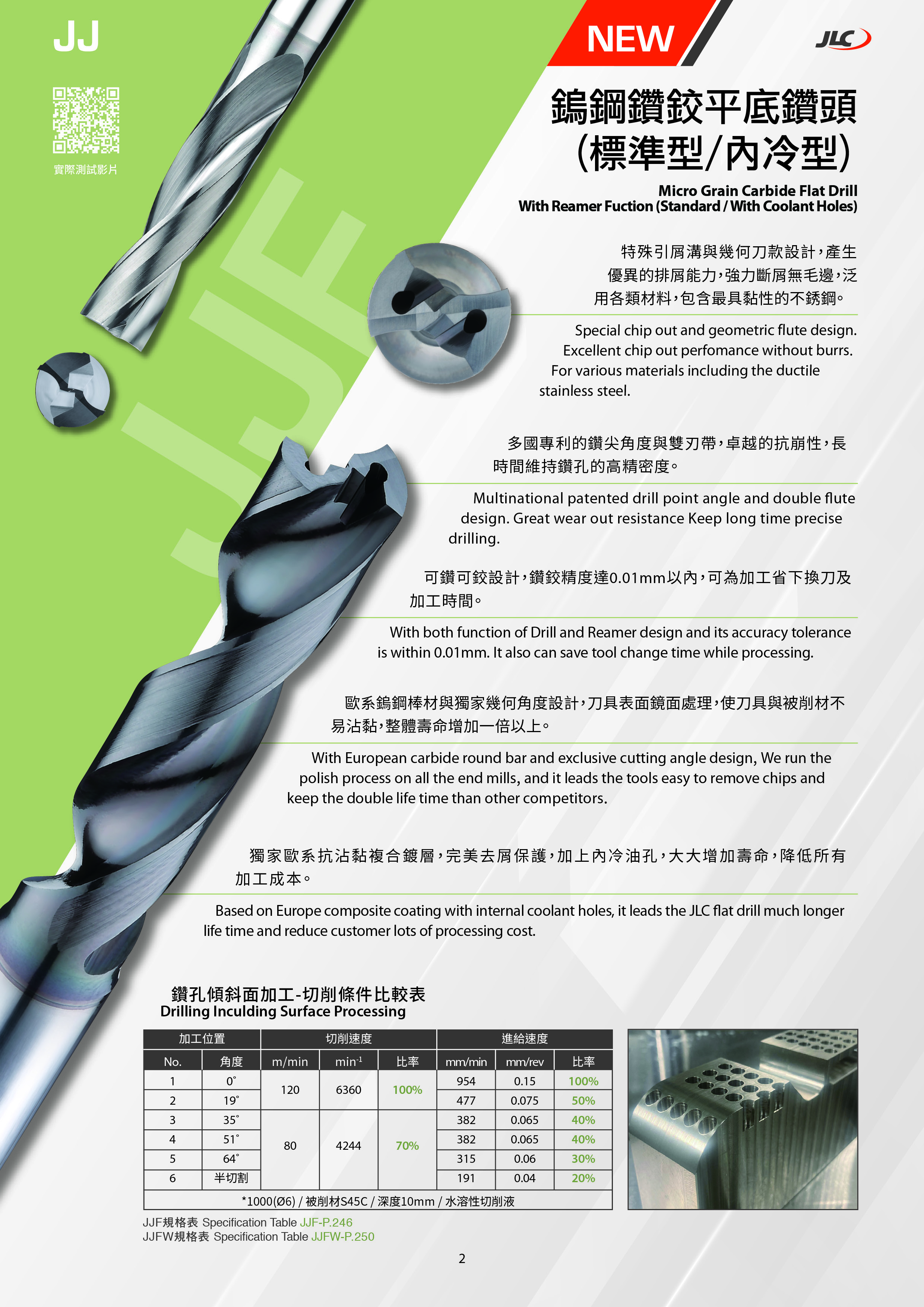

※Special chip out and geometric flute design. Excellent chip out perfomance without burrs. For various materials including the ductile stainless steel.

※Multinational patented drill point angle and double ute design. Great wear out resistance Keep long time precise drilling.

※With both function of Drill and Reamer design and its accuracy tolerance is within 0.01mm. It also can save tool change time while processing.

※With European carbide round bar and exclusive cutting angle design, We run the polish process on all the end mills, and it leads the tools easy to remove chips and keep the double life time than other competitors.

※Based on Europe composite coating with internal coolant holes, it leads the JLC at drill much longer life time and reduce customer lots of processing cost.