展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

7-LEADERS CORP.

製品の説明 :

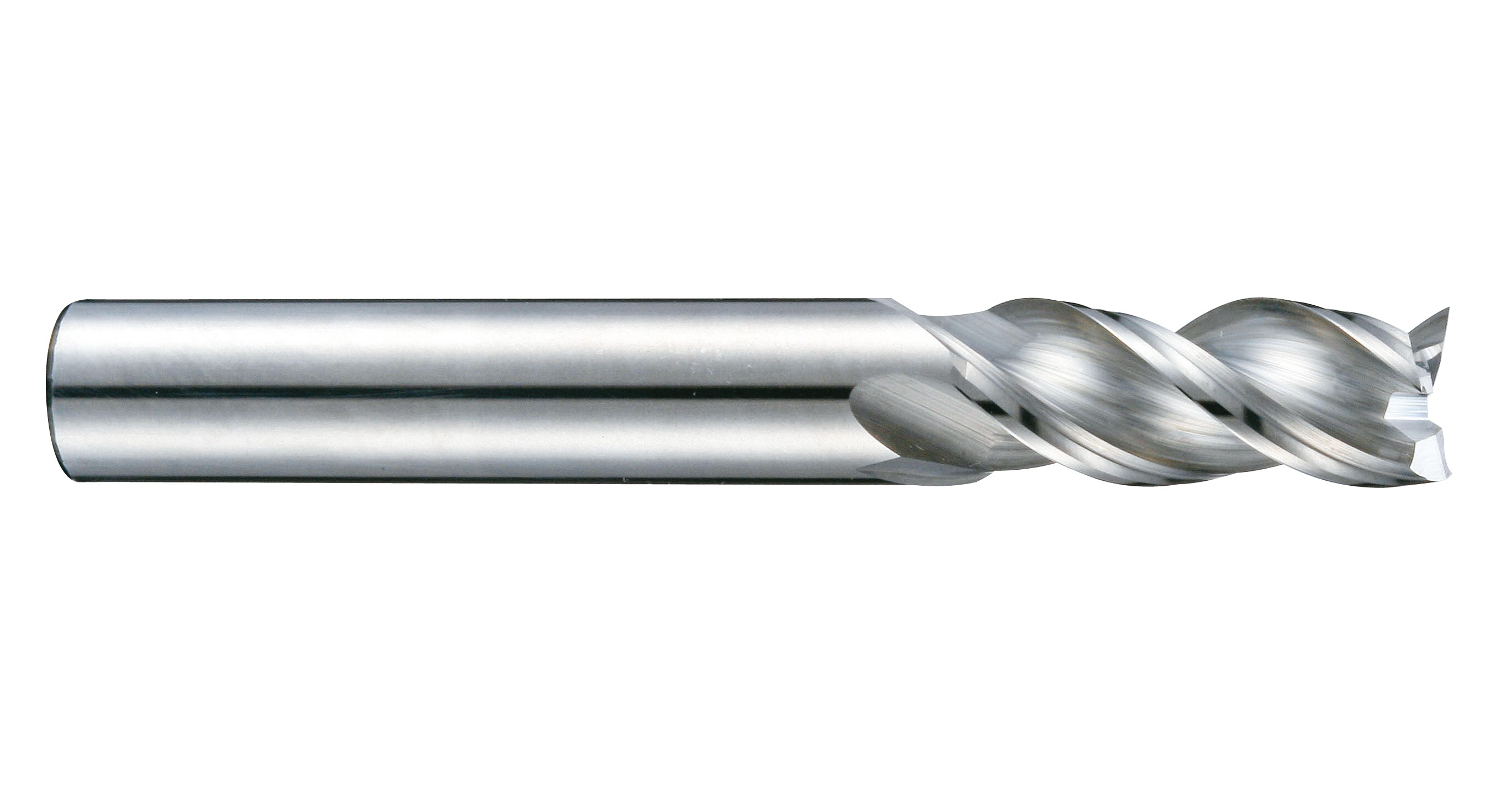

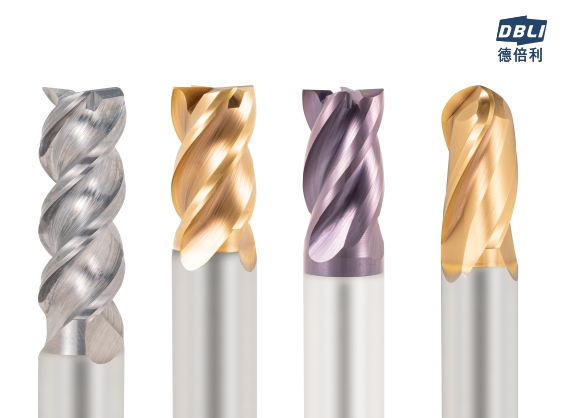

End Mills for Aluminium- 3 Flutes

Design with sharp cutting edge, high removal cutting geometry, and fine grinding smooth surface to prevent sticking problem.

Higher finishing of cutting edge to have better surface roughness after processing.

Application for roughing and finishing in various Aluminium.

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

※ We design and manufacture "speci c industry" tools

with fast delivery and great quality.

※ It can be designed according to the highest standard

and speci cation from customers. Flexible manufacturing

and accept customized tolerance.

※ From concept to nal completion. JLC customized

tools will reduce the cutter exchange labor time and

improve the e

ciency of mass production.

TAIHO TOOL MFG. CO., LTD.

製品の説明 :

The blade design that emphasizes cutting force and the unequal lead groove shape promote chip discharge and realize high-quality threading.

The lineup includes screw type for blind holes and through holes, and features that chips are discharged upwards.

The tip sample is for through holes, and the characteristic is that the chips are discharged downward.

There are two types of pipe specimens: parallel thread for mechanical bonding and tapered thread for tightness.

GUEY CHERNG TRADING CO., LTD.

製品の説明 :

SIMPLE

Tool is clamped in 8 seconds by pushing

only one single button.

SAFE

No heat up – high clamping force. Excellent vibration dampening.

HIGH PRECISION

Toolholder runout TIR ≤ 1 μm

Total system runout TIR ≤3 µm at 3 x D.

powRgrip®

The tool clamping system of today and the future.

GUEY CHERNG TRADING CO., LTD.

製品の説明 :

Burnishing is a process employed in the micro finishing of surfaces to obtain smooth and hardened surfaces with high load bearing capacity and good running properties, without machining.

Roughness after burnishing ≦Ra 0.2

DIATEC CO., LTD.

製品の説明 :

DR. KAISER修整主軸有多種型號,可以針對客戶工件需求提供適合的客製化產品。具備以下特點:

1.易於在齒輪磨床上安裝。

2.具剛性的液壓主軸安裝/夾緊系統。

3.具廣泛的轉速範圍,可適用同向或逆向修整。

4.配備空氣密封/過濾系統、溫度傳感器、主軸和鑽石修整輪的微平衡系統。

5.配備接觸性傳感器,自動優化修整過程及速率。

6.高軸向和徑向的跳動精度。

MONGTEC PRECISION INC.

製品の説明 :

BODY

Re-designed main body to improve rigidity and reduce vibration. Specially treated corrosion resistant steel body.

Bearings

Angular contact preloaded ball bearings of precision class P4 / ABEC 9.

Bevel Gears

Gleason computer based calculations for the Gleason cut spiral bevel drive gears with ground teeth in order to guarantee a bigger torque.

Torque and Speed

With Speeder 1:4:32,000 Rpm

(Standard 1:1:6000~12000Rpm)

Max Torque:160Nm

Internal Coolant

Max Pressure:70-100 bar

7-LEADERS CORP.

製品の説明 :

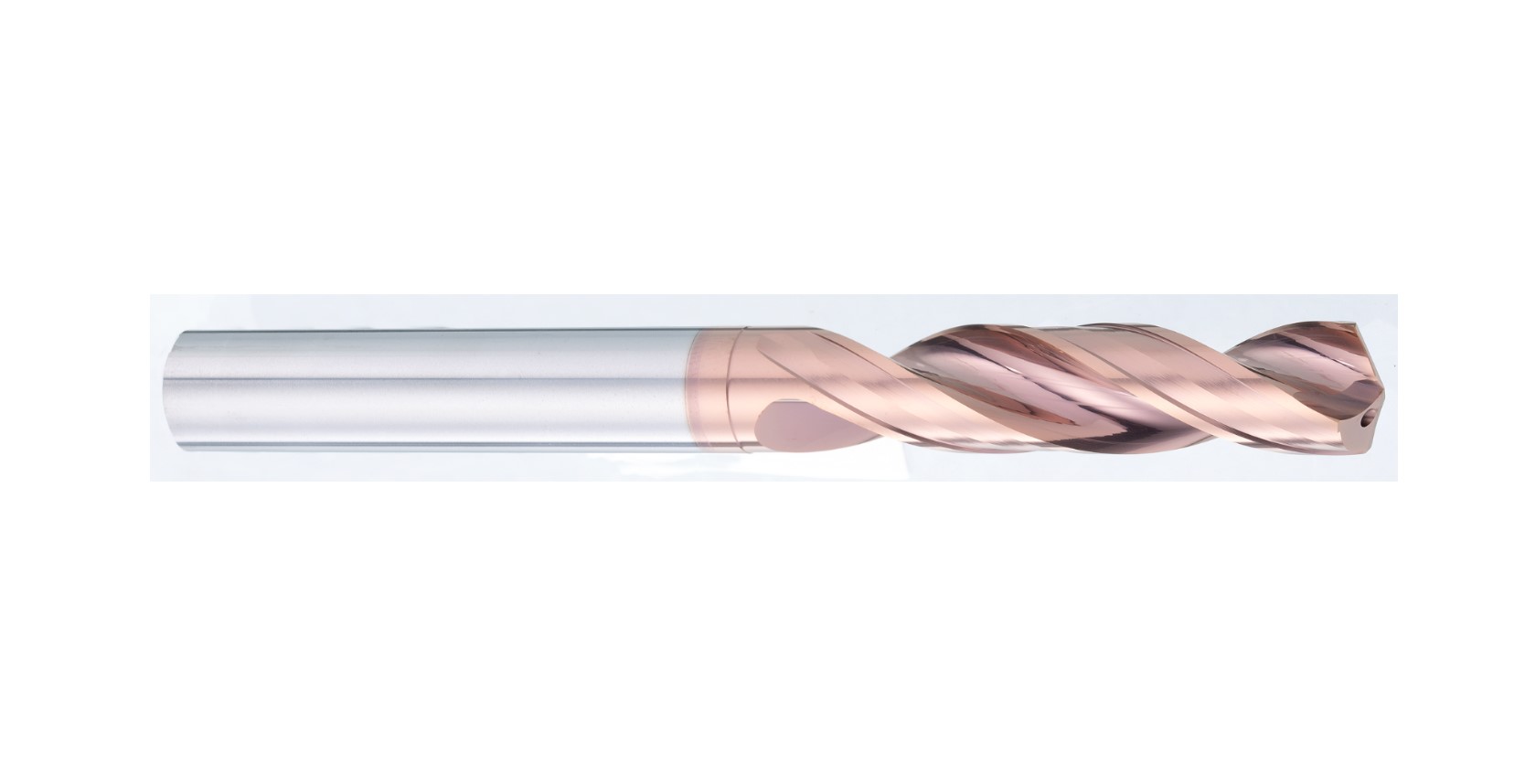

JIS 3XD Drills with Oil-Feed

140° S-shape drill tip design to reduce axial force.

Design with groove shape to provide higher chip removal rates.

Good wear resistance and lubrication with Nano multilayer coating.

Oil-feed design could reduce temperature effectively and increase chip removal rates during cutting process.

Application for drilling with Steels which under HRC48, Cast Iron…etc.

Suitable for drilling with 3XD depth.

DEEP JET INDUSTRY CO., LTD.

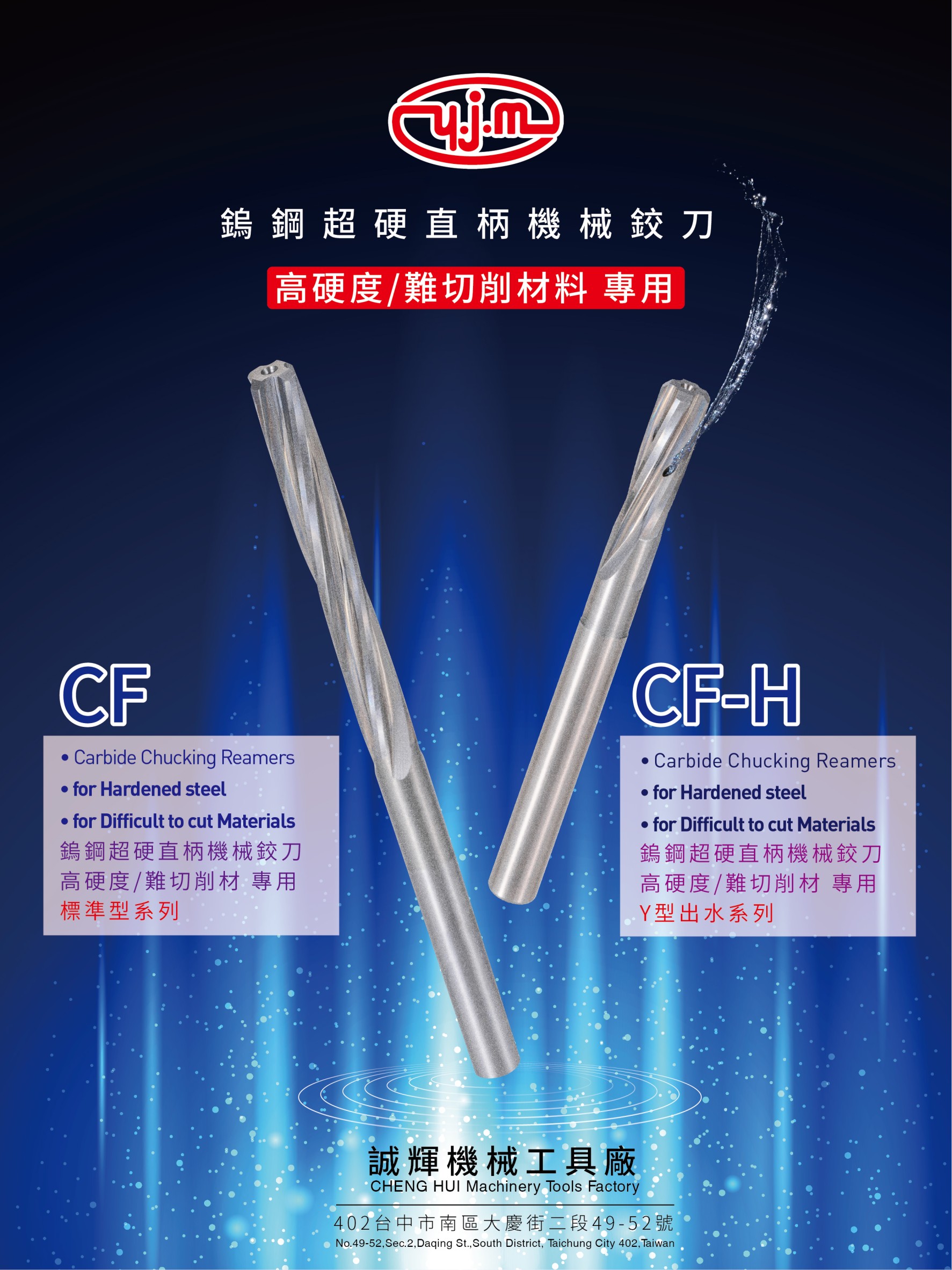

製品の説明 :

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.