展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

PARFAITE TOOL CO., LTD.

製品の説明 :

1.3μ以下跳動精度,可減少刀具磨耗,提升面粗度(刀具懸伸,為柄徑4倍量測值)2.具減振功能設計,可降低阻尼,提高加工穩定性3.夾刀操作簡單,縮短換刀準備時間4.重覆精度佳,可大幅節省校刀時間

PRAISE PRECISION IND. CO., LTD.

製品の説明 :

NEW PRODUCT- CUTTING KNURLING TOOLS USED ON LATHE

Method of forming knurling

1. Press forming(Form knurling)

Press knurling tool directly to workpiece in turning on the lathe

to form the patterns. Pressure is applied to the lathe spindle, and the outside diameter of workpiece will become bigger

2. Cutting forming(Cut knurling)

The knurling tool is applied to workpiece just like cutting, less pressure

to lathe spindle and less machining resistance, forming a clear patterns, the best choice for using on CNC lathes

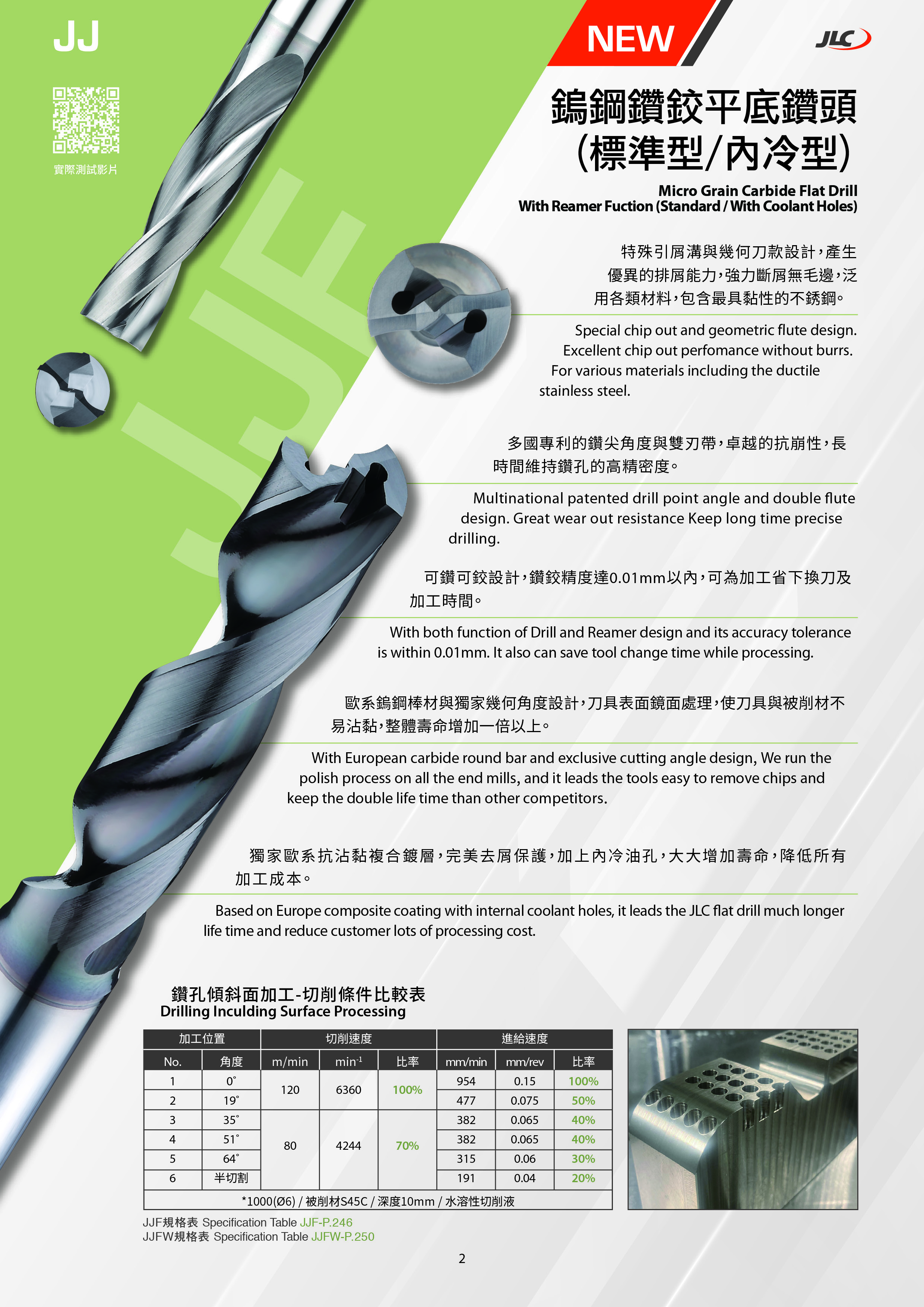

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

※Special chip out and geometric flute design. Excellent chip out perfomance without burrs. For various materials including the ductile stainless steel.

※Multinational patented drill point angle and double ute design. Great wear out resistance Keep long time precise drilling.

※With both function of Drill and Reamer design and its accuracy tolerance is within 0.01mm. It also can save tool change time while processing.

※With European carbide round bar and exclusive cutting angle design, We run the polish process on all the end mills, and it leads the tools easy to remove chips and keep the double life time than other competitors.

※Based on Europe composite coating with internal coolant holes, it leads the JLC at drill much longer life time and reduce customer lots of processing cost.

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

The “ i-Center ” is a trademark of Nine9,

the developer of the first indexable center drill in the world.(Patented)

Offering an indexable insert system for the 1st time, Nine9’s “i-Center ” design improves your process performance. Shortens set up and center drilling time.Increases tool life and reduces tooling costs.

● High Speed, High Feed Rate

• The special ground insert and rigid holder design facilitate high performance speed and feed rates. For example, drilling alloy steel

at 6000 rpm and feed rate of 600 mm/min. (0.1 mm/rev.).

● Excellent Repeatability

• The positioning repeatability of the insert is within 0.02 mm

(.0008”) in radial direction, thus ensuring conformity to any national

standards.

● Easy Tool Length Setting

• The axial position accuracy of the insert is 0.05 mm (.002”). It is

not necessary to reset the tool length when changing or cutting edge.

● Extended Tool Life

• Coolant can be supplied through the center of the holder to increase performance and extend tool life.

• Insert geometry, grades and coating process are specifically engineered for centering applications.

DIATEC CO., LTD.

製品の説明 :

DR. KAISER修整主軸有多種型號,可以針對客戶工件需求提供適合的客製化產品。具備以下特點:

1.易於在齒輪磨床上安裝。

2.具剛性的液壓主軸安裝/夾緊系統。

3.具廣泛的轉速範圍,可適用同向或逆向修整。

4.配備空氣密封/過濾系統、溫度傳感器、主軸和鑽石修整輪的微平衡系統。

5.配備接觸性傳感器,自動優化修整過程及速率。

6.高軸向和徑向的跳動精度。

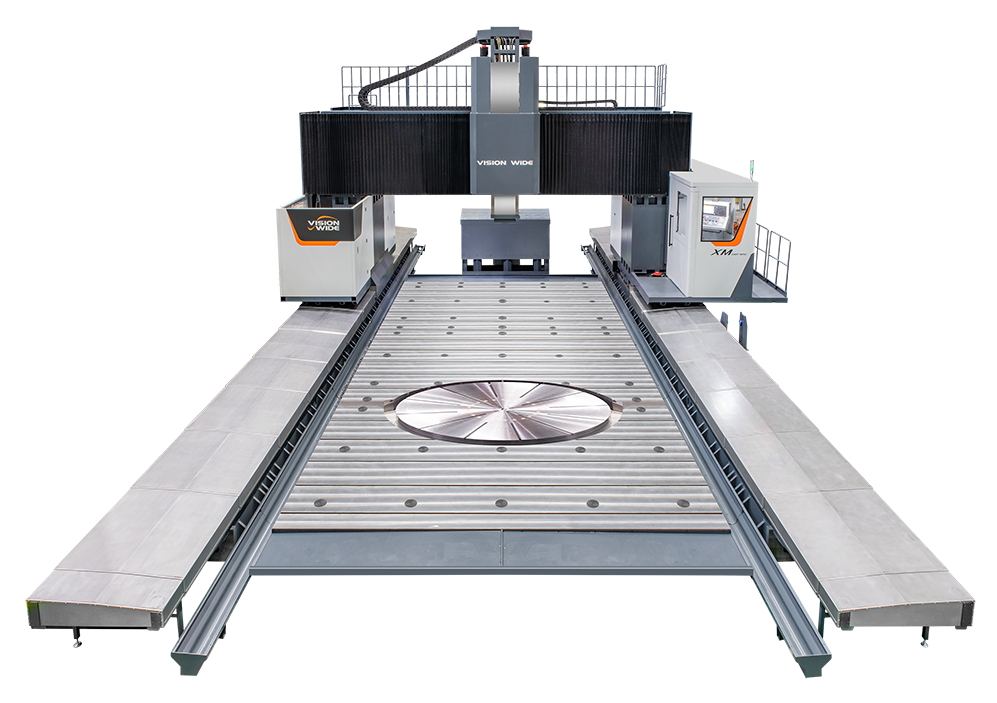

VISION WIDE TECH CO., LTD.

製品の説明 :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

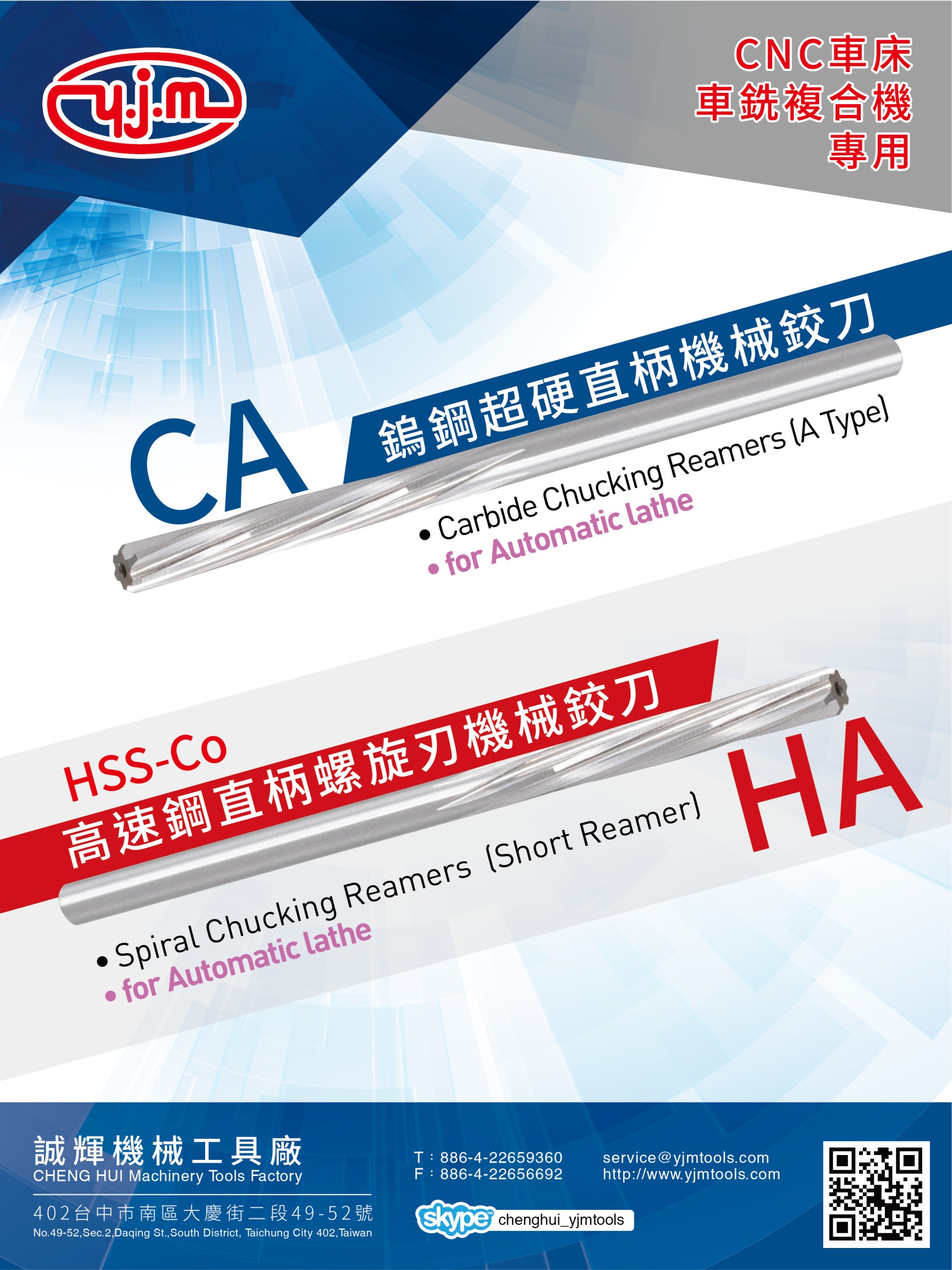

CHENG HUI MACHINERY TOOLS FACTORY

製品の説明 :

Adjustable reamer, Carbide reamer, H.S.S reamer,

All kinds of reamers Manufacturer.

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

This is a revolutionary new concept of engraving tools with indexable carbide inserts. They offer you the ability to produce HIGH QUALITY ENGRAVING in most materials.

The latest coated carbide grades help you to obtain higher speed and feed rate, dramatically reducing your cycle time.

● High Positive Rake Angle

• Indexable insert.

• Suitable for engraving all types of materials, such as plastic, non-ferrous metal, aluminum, copper, carbon steel and stainless steel.

● Multi-Side Grinding

• Full peripherally ground insert to ensure efficient repeatability.

• It performs excellently without producing any burrs, especially in copper, aluminum and stainless steel.

● High Speed, High Feed Rate

• Designed to run at high speed, up to 40,000 r.p.m.

• Feed rate 0.08mm (0.003”) / rev. apply to aluminum; 0.05mm (0.002”) / rev. apply to stainless steel.

• Reduces engraving cycle time!

● Economical

• Each indexable insert has 2 cutting edges.

• No resharpening required. Tool length is unchanged.

• No need to reset after changing insert or cutting edge.

• Excellent repeatability!

CHENG HUI MACHINERY TOOLS FACTORY

製品の説明 :

For Automatic lathe

Material: HSS-Co / Carbide

Tolerance:(+0~<+0.005)mm