展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

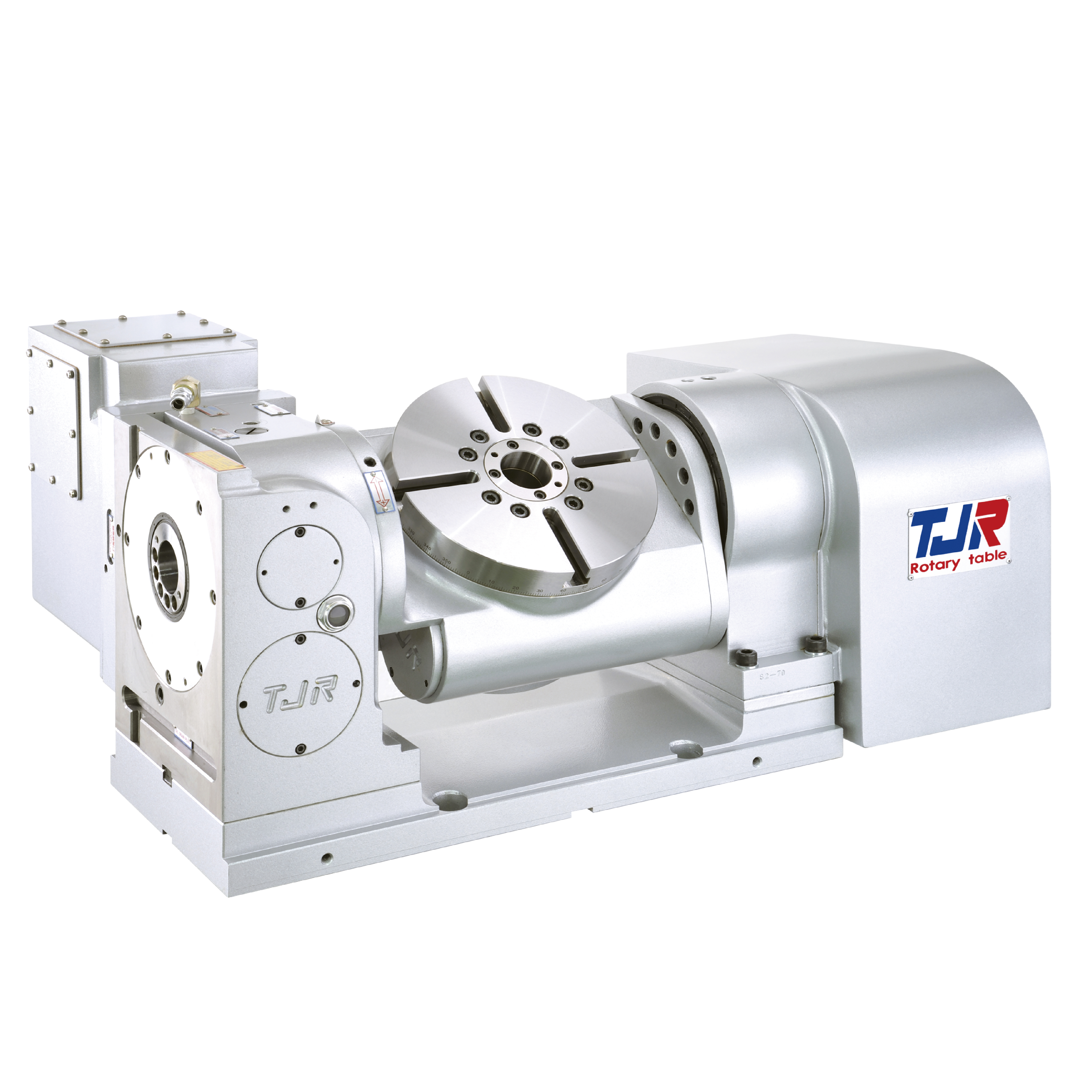

TJR PRECISION TECHNOLOGY CO., LTD.

製品の説明 :

① Both the tilting axis and rotary axis use large-diameter radial & axial bearings.

② Because the tilting axis normally needs to bear heary load, Japanese-made worm and worm gear are employed to improve wear resistance and precision of the tilting axis.

(Its wear life is 2.6 times longer than aluminum bronze PBC3.)

③ Anti-wear alloy steel worm gear is optional.

④ A hydraulic brake for the tilting axis is optional.

YEU-LIAN ELECTRONICS CO., LTD.

製品の説明 :

The Manual Pulse Generator Engraving Handwheel by YEU-LIAN is designed for CNC operation panels, enhancing applicability through metalworking materials. It protects against dust, water, and oil, with an optical rotation, non-contact detection structure ensuring no vibration affects signal output. The encoder withstands 3 million cycles maintaining high precision, and features anti-static design, wide voltage range (DC5V to 24V), high reliability, and strong consistency. It's easy to install, suitable for various automation equipment, and CNC systems, ideal for CNC MPG pendant controllers and CNC operation panels.

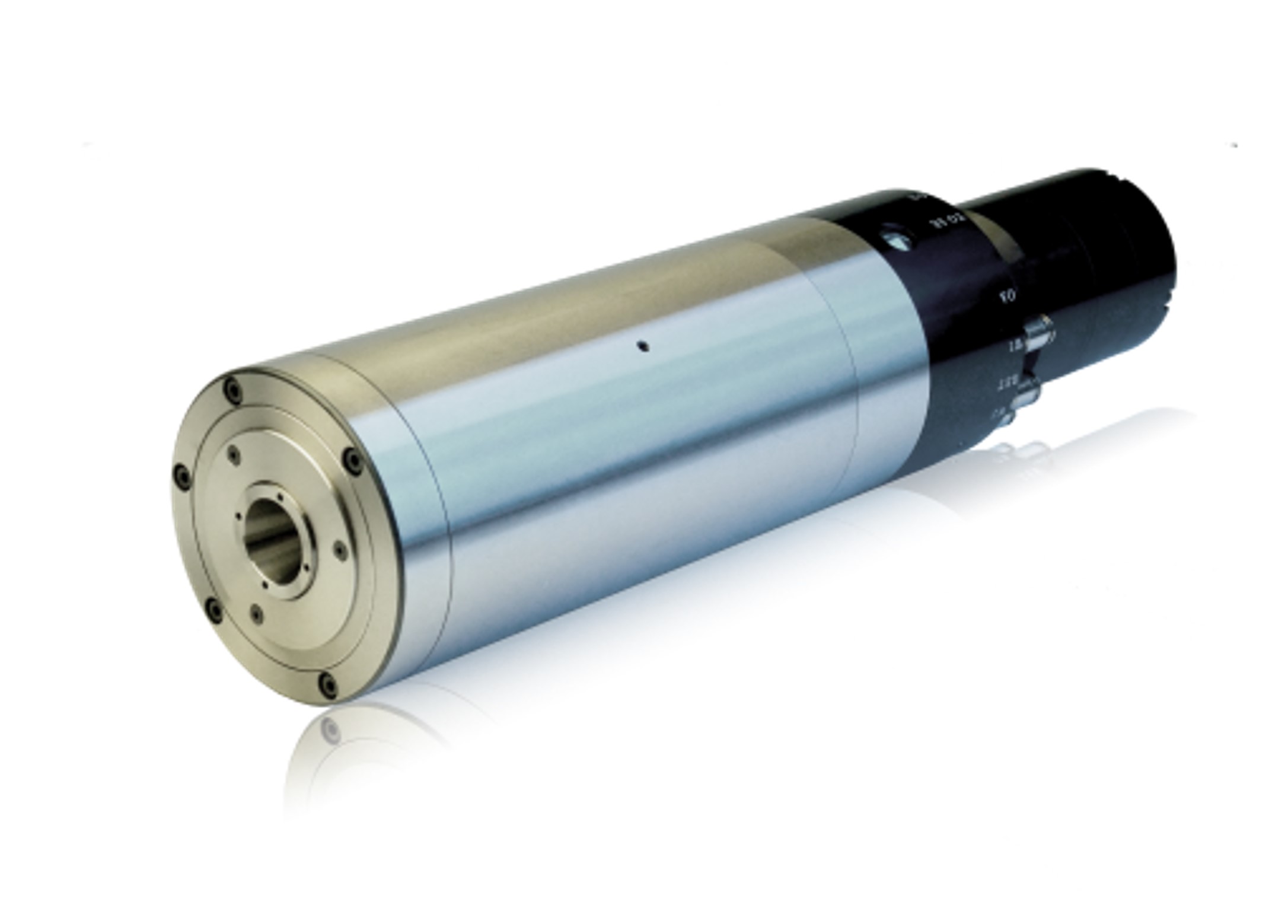

SPINDLEX TECHNOLOGIES CO., LTD.

製品の説明 :

Spindle housing diameter : 100mm

Tool interface : HSK-E32

Maximum speed (rpm) : 30,000 RPM

Lubrication : Grease

Motor power : 3.5/5.5 Kw

Go power machinery CO.LTD

製品の説明 :

Gutian horizontal cam fix-axis rotary table has internal cam roller transmission mechanism.

There is backlash-free rolling drive between cam and needle bearings pre-load, no sliding

friction or backlash. Its positive reverse motion has high repeatability accuracy without the

need for periodic calibration and adjustment. Its accuracy is not affected by rising

temperature. Improving the quality of multi-axis machining parts can greatly reduce defective

rate of machined parts.

HAINBUCH GmbH

製品の説明 :

Ideal for today's high paced manufacturing environment!

Convenient, that the HAINBUCH quick change-over systems fit on all your machines. Even better, that you can change your clamping devices in a matter of minutes, thus earning money quicker and allowing you to manufacture job-oriented. And, thanks to our unique technology, you will achieve a repeatability of ≤ 0.003 mm on the interface.

However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times,

your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or precision.

Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers. We will simply adapt them to our interface.

HAINBUCH GmbH

製品の説明 :

HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings are made of case-hardened chromium-nickel-steel and have segments that are extremely hard and rigid. All contact surfaces are completely ground in one operation guaranteeing optimum concentricity.

Mandrels with hexagonal clamping geometry, the MAXXOS mandrels. are the optimized version for round MANDO mandrels. Thanks to the hexagonal geometry, a previously unattained clamping force and rigidity with the best precision is now achieved for internal clamping. The robust and powerful clamping mandrel delivers first-class values in terms of dirt density. The force is transmitted by positive locking, in addition to optimum process reliability and long maintenance intervals.

AUTOGRIP MACHINERY CO., LTD.

製品の説明 :

◎ Second Collet Changes Slash Setup Times.

◎ Industry-Leading Gripping Range.

◎ Ultra-Precision Accuracy.

◎ Parallel clamping over the entire clamping length

◎ Extreme Grip Force = Most Aggressive Chip Removal/Fastest Cycle Times.

◎ Maximum Rigidity Produces Superior Part Finishes.

◎ Best Tool Clearance - Critical For Live Tooling.

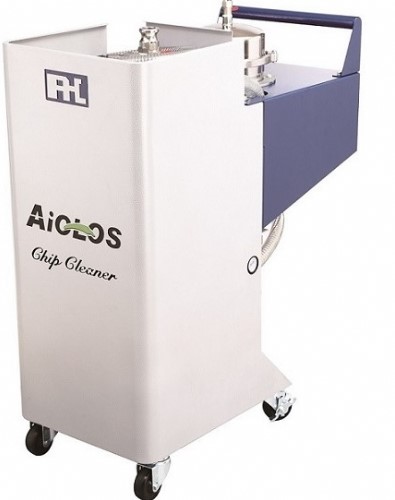

HC FENG CO., LTD.

製品の説明 :

FOODIE (Chip/Sludge Removal Machine) works for :

Filtration/Removal of excess components

Chip/Sludge Removal

Fine Chip Removal

No downtime

No consumables

Backwater automatically & simultaneously

Air pressure drive w/o a plug

Vertically fast filter drying up to 90% efficiency

Precision filters effective up 20% for super filtration micro-fines

Easy to move

Filter accuracy can be adjusted

Extend cutting fluid life