展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

PEI CHIANG MACHINERY CO., LTD.

製品の説明 :

S系列經濟型 產品特色:

● 半油性切削液專用

針對水性切削液設計之HEPA濾材,有效過濾水霧懸浮微粒

● 高效淨化有毒物氣

再過濾油霧回收機餘氣、PM2.5懸浮微粒60%,配合二段式高壓油霧回收機,整體過濾效能達95%

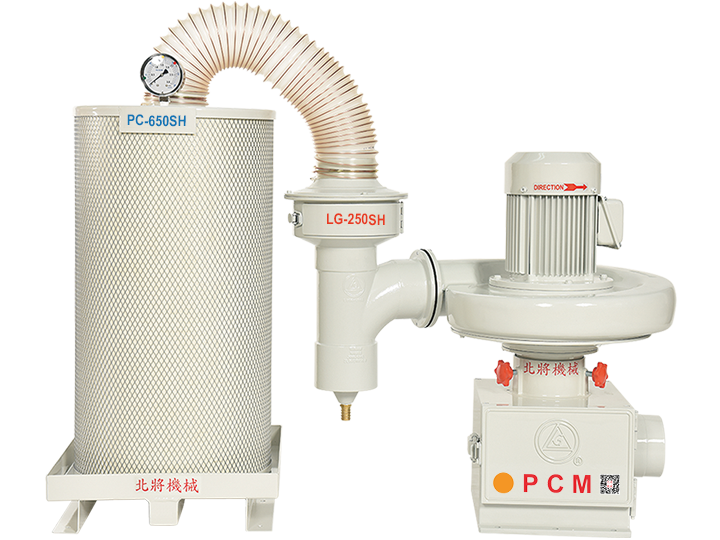

油霧回收機本體特色 :

●機體材質鋁合金成型,重量輕,堅固耐用

●強力高風壓,最大可達320mmAq流量流速穩,過濾效能高

●使用感應式馬達,電量省 散熱快 適合長時間運轉

●結構式原理回收油霧,直立式設計,不震動,低噪音

●安裝容易,不佔空間,使廠內機械移位佈置更容易

●捨棄式濾網,10秒快速更換,保養容易,工安無慮

分離式油煙處理座特色

●標配之壓力錶:可輕易檢知是否有阻塞的情況 、 判斷濾材更換時間

●專利結構設計:由上往下之設計原理,以高風壓加速濾材所吸附的油氣集結快速垂降, 使壽命有效延長

●分離式之設計:因應現場需求,可直接安裝於機台上方或任意位置

●彈性多功組合:可單獨選購或配合任何有動力送風之末端空氣處理

● 免保養易更換:濾材無需保養,分離式之設計使濾材更換更加容易

適用範圍:

CNC車床、CNC铣床、CNC綜合切削加工機、CNC磨床、放電加工機、滾齒機、洗淨槽、防鏽油噴霧回收及會產生

白煙、細油氣、水霧、油霧之各種設備的回收淨化處理。

選配項目:

● 活性碳AC-650 ● 油煙處理器S-350 ●油煙處理器SH-650 ●側掛鐵架 ●直列式四腳架 ●並列式四腳架

Tokai Spring industries, Inc.

製品の説明 :

Tokai spring is committed to manufacturing small-lot and custom-made spring orders because we believe that there are customers who need highly specialized, high quality spring products. Tokai spring’s mission is satisfying or even exceeding our customer’s requirements.

HC FENG CO., LTD.

製品の説明 :

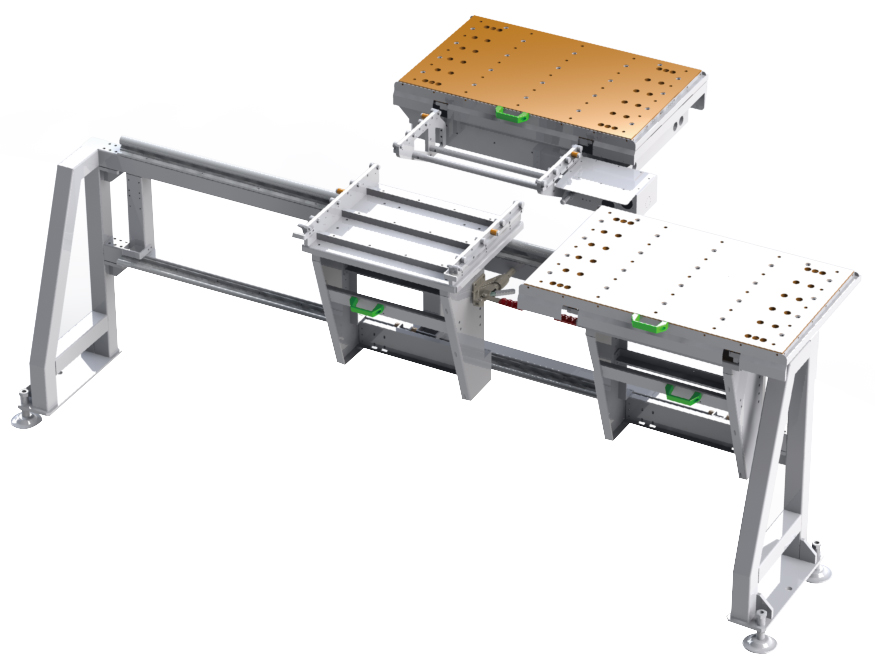

FOODIE (Chip/Sludge Removal Machine) works for :

Filtration/Removal of excess components

Chip/Sludge Removal

Fine Chip Removal

No downtime

No consumables

Backwater automatically & simultaneously

Air pressure drive w/o a plug

Vertically fast filter drying up to 90% efficiency

Precision filters effective up 20% for super filtration micro-fines

Easy to move

Filter accuracy can be adjusted

Extend cutting fluid life

GREEN ECO PRO CO. LTD.

製品の説明 :

Oil Mist Collectors

Smart Alert Flagship Series

When the high-speed processing material that produce heat, and then heat to steam out the water, if the coolant tank of waste oil or other oil without correct handle, this time Processing heat will produce oil mist.

With one integrated mechanical design aesthetics

High efficacy with Mini Size

Low Decibel 65 db

Vibration rate G2.5mm/s

Unique development 2D turbine Wheel

Recycle oil above 99%

Intelligent Alert

AUTOCLAWS PRECISION MACHINERY CO., LTD.

製品の説明 :

1. Suitable for round-bar shape objects to clamp before cutting process.

2.Using the advanced high-strength alloy steel, the key components have been treated with hardening which is strengthening the structure and enhancing the stability with accuracy and durability.

3.Large caliber design allowing the bar material go through, furthermore, it can be complemented to automatic processing eqipment for enhancing the machining efficiency.

4. The chucks complement the rotary hydraulic cylinder to provide a stable pressure for various chucking conditions.

5. Professional precision grinding makes it high-precision, precision repeat clamping accuracy, high clamping force.

YOKE INDUSTRIAL CORP

製品の説明 :

1. 360° rotation and 230°pivot

2.Rotatable under load due to its unique ball bearing design.

3.Manufactured in accordance with EN1677‐1 and the requirements of ASME B30.26

4.Certified by DGUV GS‐OA‐15‐04

5. Forged alloy steel, quenched and tempered

6.With the Grade 100 High‐strength alloy steel, WLL is increased without increasing swivel size compared to other Yellow Point models.

7.4:1 Design factor

8.100% Magnaflux crack detected

9.Proof load at 2.5 times the WLL

10.Fatigue rated for 20,000 cycles at 1.5 times the WLL