展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

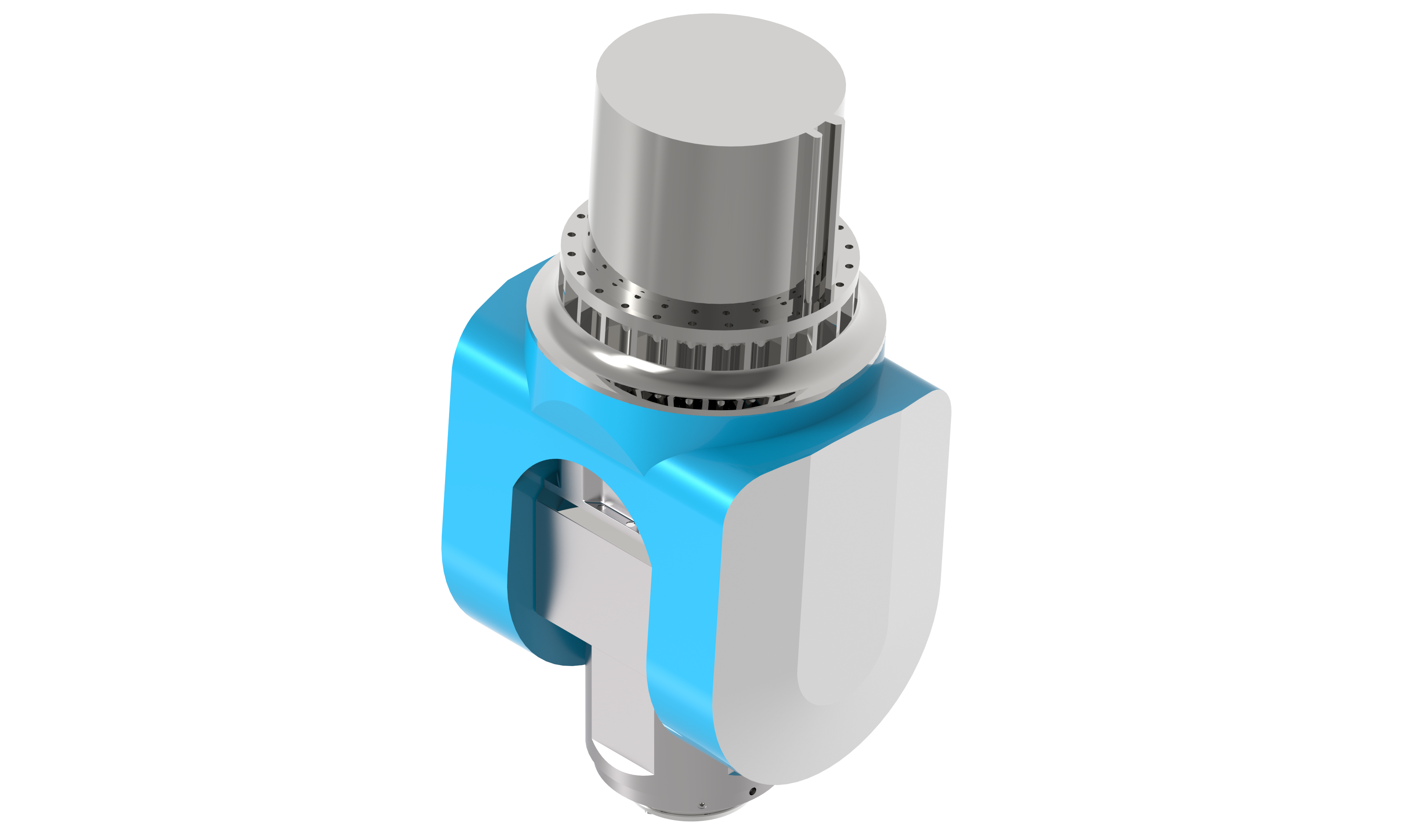

GP MACHINERY CO., LTD.

製品の説明 :

AREA OF USE:

Processing structural components for trains and the air and space travel industries

Construction of models and prototypes

Design

RAW MATERIALS AND PROCESSING:

Finishing steel and cast iron

Roughing aluminium, Zamac, CFRP/GFRP

Artificial materials, wood and ureol

COMETECH TESTING MACHINES CO., LTD.

製品の説明 :

RS-485

型號:K0118-000F51A2

通訊速度:9600、19200、38400、115200、921600、1M、2M bps

連接器型式:2P歐式端子

尺寸:38 x 31 x 15 mm

使用環境溫度:0°C~55°C

RS-232

型號:K0118-000F41A2

通訊速度:9600、19200、38400、115200 bps

連接器型式:D-Sub 9P母座

尺寸:33 x 31 x 15mm

使用環境溫度:0°C~55°C

CAN Bus

型號:K0118-000F61A2

通訊速度:1M bps

連接器型式:2P歐式端子

尺寸:38 x 31 x 15 mm

使用環境溫度:0°C~55°C

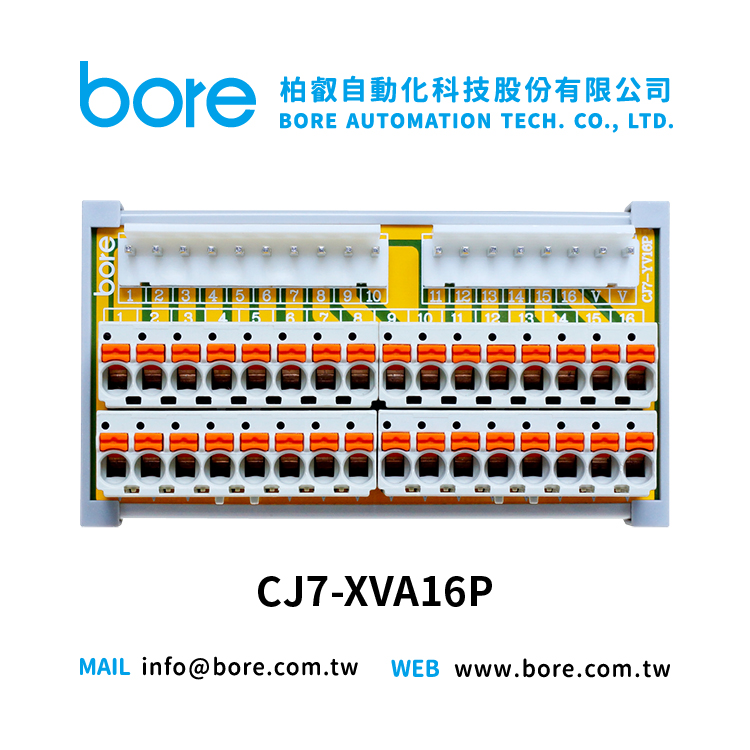

LNC TECHNOLOGY CO., LTD.

製品の説明 :

‧Pulse or Digital communication type

‧ EtherCAT protocol provides high flexibility of peripheral equipment connection control

‧6 path 32 axis control (max.)

‧High-speed and high-precision compensation to meet advanced turning and milling applications

‧Dual system, double feedback

‧Provide secondary development tools: HMI/PLC/Macro

‧Equipped with LNC smart vibration sensor to provide value-added functions: abnormal vibration detection, tool wear detection...and so on

‧Applications: high-speed lathe, turning-milling complex machine, dual-system lathe, double feedback lathe, gear hobbing machine

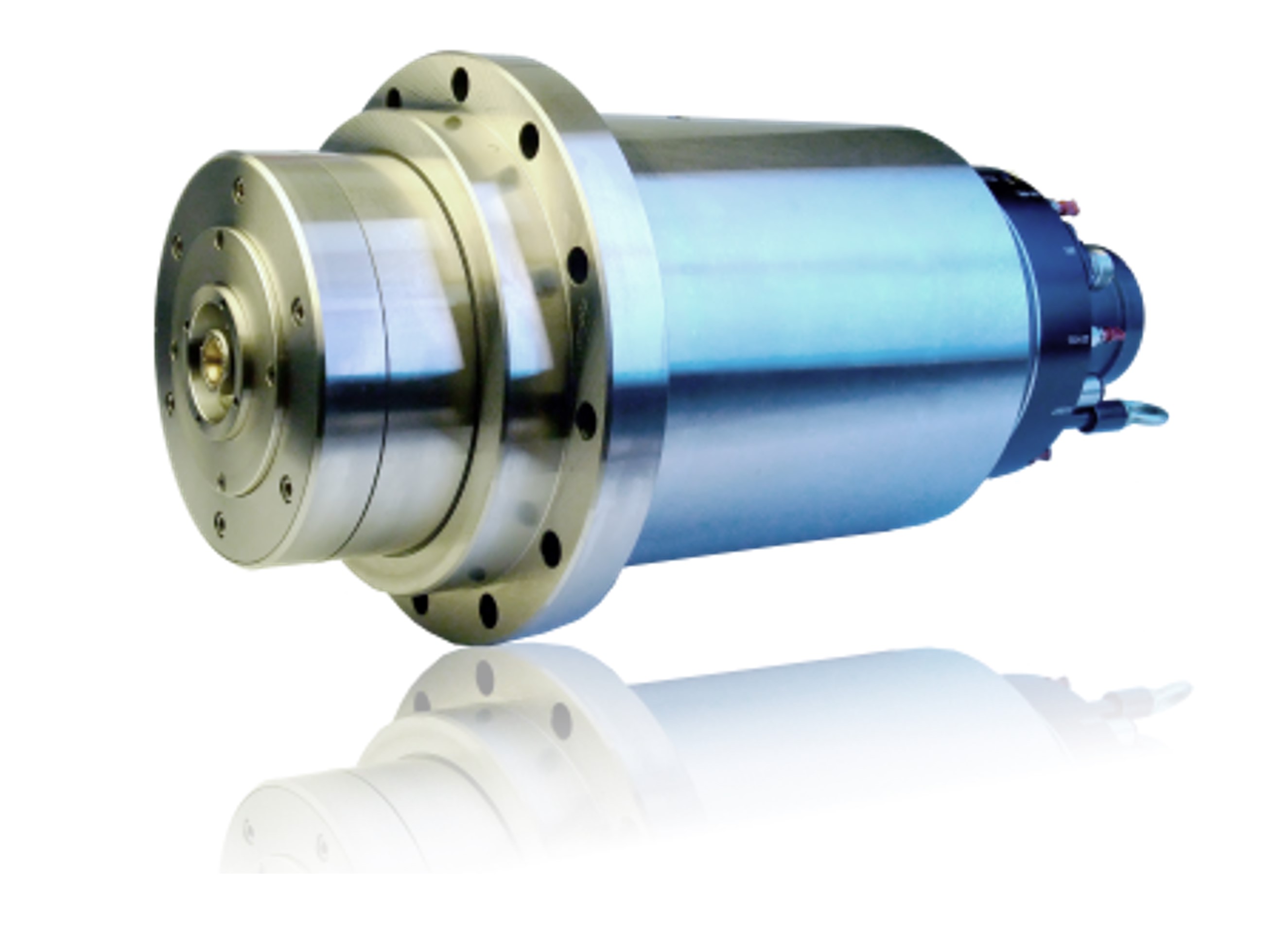

SIEMENS LTD., TAICHUNG BRANCH OFFICE

製品の説明 :

Optimizing the machining process using real-time data

Machine tool users incur unnecessary costs as a result of tool breakages, unexpected surface quality anomalies, cutting tools being replaced too early, and longer non-productive machining times. Do you know how to avoid these pitfalls and save money by leveraging your real-time cutting data?

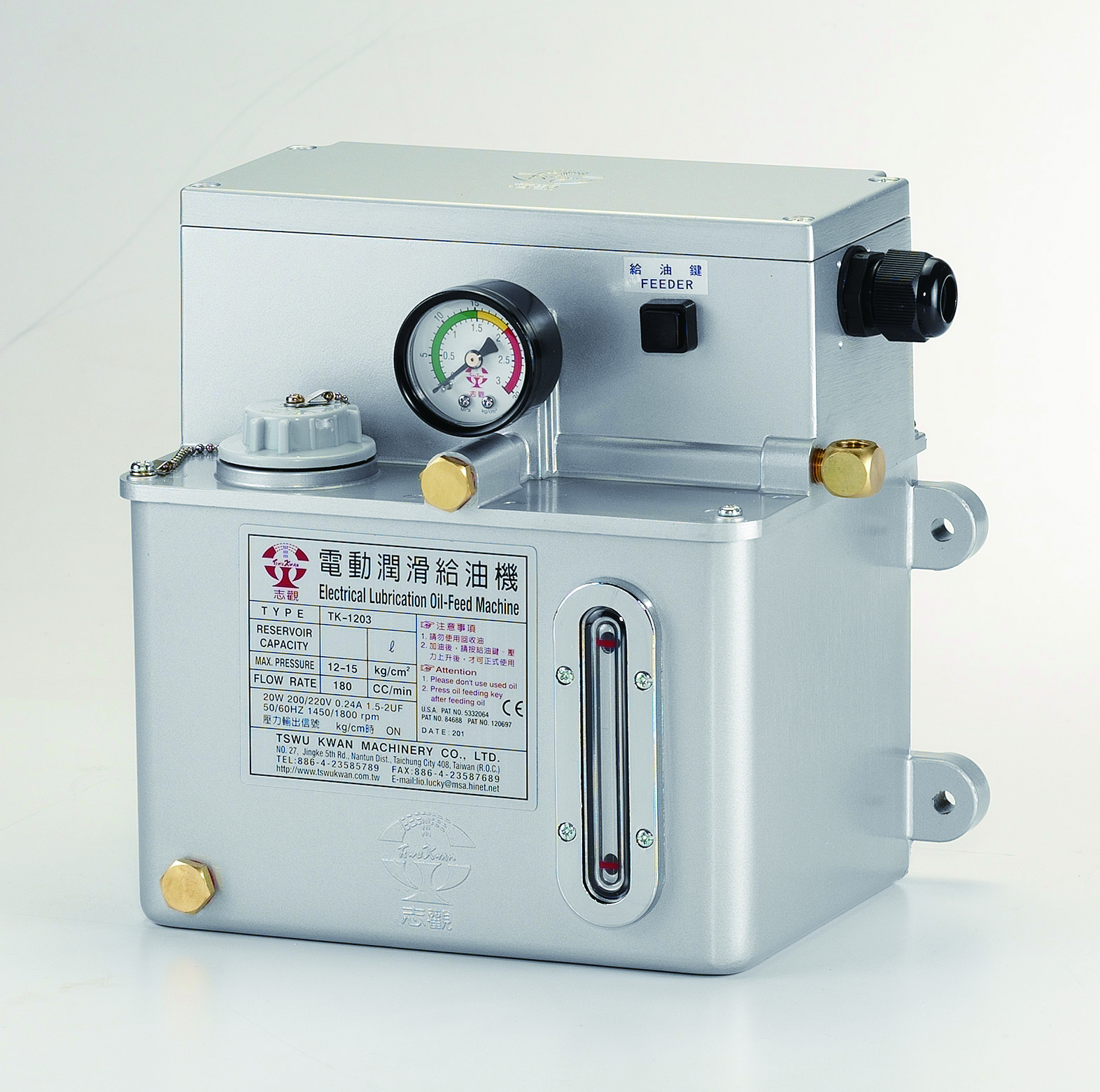

COMETECH TESTING MACHINES CO., LTD.

製品の説明 :

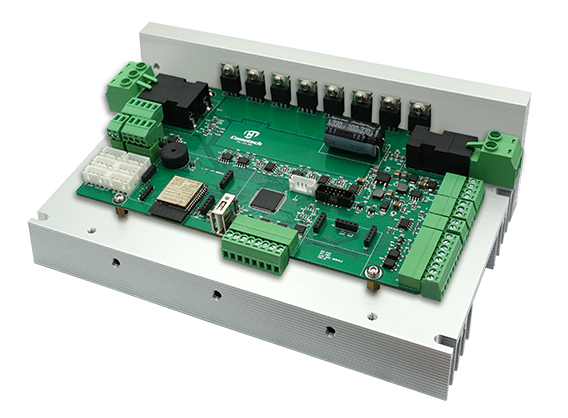

Besides adjusting the motor speed, users can set up detailed motor-related data settings with our C2 series driver. Its multifunctional integrated design is the main feature and advantage for saving costs and reducing external components.

Users can connect directly to the dedicated software for easy parameter tuning and configuration with the built-in Wi-Fi module. An over-the-air firmware update without assembling the driver from devices can improve maintenance efficiency and convenience.

Moreover, the driver features a modular expansion design that allows flexible extensions of communication formats, wireless screen modules, and more to meet various user needs.

※Specification

-Rated Voltage: DC 12~48V

-Rated Output: 800W

-Rated Current: 35A

-Applicable Motor: BDC, BLDC

-Motor Feedback: Hall Sensor, Sensorless; Encoder input signal is available

-Communication Interface: Built-in Wi-Fi module and RS-485; RS-232, CAN Bus for options

-Speed Control: Analog input, Digit input, PWM, Command sources

-Display: 2.8" wireless color touch screen for options

-Software: Equipped with dedicated motor monitoring software which is available to connect with mobile devices (smart phone, pad, notebook, etc.) through Wi-Fi.

※Features

-Integrate multiple functions to reduce the external components' cost

-Monitor the motor's status such as voltage, current, speed, etc. through dedicated software

-Data setting and devices' status monitoring by dedicated software through Wi-Fi connection

-Support different motor control modes (revolutions, distance, operation speed, etc.) and multi-step programmable settings

-Modbus-compatible driver for various host controllers.

-Over-the-air firmware update

-Multiple I/O (open collector) for flexible expansion of different applications