展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

YOKE INDUSTRIAL CORP

製品の説明 :

1. Size from M8 to M90 to fulfill your demand

(M8 ※ 0.3t _ M90 ※ 40t)

2. Design Factor 4:1, Working load limit could be up to 40 tons

3. Lifting point is made by forged alloy steel, quenched and tempered

4. Suitable for all loads which swivel and tilt especially for heavy duty, material handling, mold & die industries.

5. Ball bearing inside is easier for flipping working piece and rotation.

6. Light weight, High Performance, easily for using

7. Deliver with test certification to guarantee your safety

MONGTEC PRECISION INC.

製品の説明 :

BODY

Re-designed main body to improve rigidity and reduce vibration. Specially treated corrosion resistant steel body.

Bearings

Angular contact preloaded ball bearings of precision class P4 / ABEC 9.

Bevel Gears

Gleason computer based calculations for the Gleason cut spiral bevel drive gears with ground teeth in order to guarantee a bigger torque.

Torque and Speed

With Speeder 1:4:32,000 Rpm

(Standard 1:1:6000~12000Rpm)

Max Torque:160Nm

Internal Coolant

Max Pressure:70-100 bar

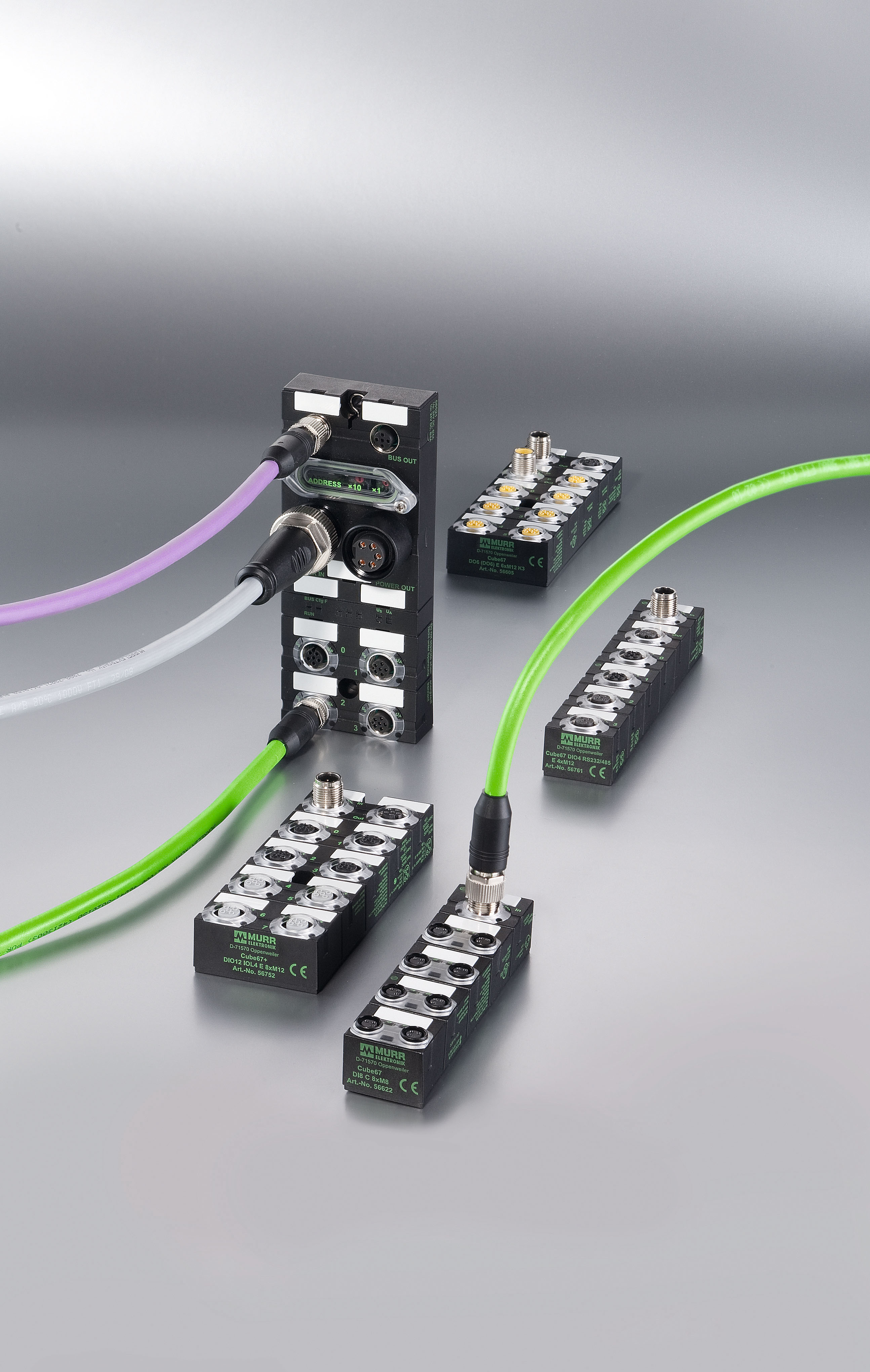

PRECISION MOTION INDUSTRIES, INC.

製品の説明 :

●Equipped with lubrication unit G1, it can reduce the amount of oil used to meet the economic and environmental protection needs in response the carbon reduction trend.

●In required clean environment where it is necessary to avoid oil scattering, and also prevent to temperature rise caused by injecting too much oil.

●Contains more than 70% oil and can run more than 20,000km without oil supply, also easy to supply oil in difficult filling places and saving a lot of maintenance time.

●Even in an environment with water, there is no need to worry about oil and grease being washed by water.

●The extra lubrication unit equals an extra layer of scraping effect, which greatly reduces the chance of foreign matter invasion.

SHENG FENG TECHNOLOGY CO.,LTD

製品の説明 :

Cross roller bearings consist of inner rings, outer rings, spacer retainers and cylindrical rollers cross arranged on the V-shaped 90° groove between the inner and outer rings. This structure can withstand radial, axial and moment loads in all directions because the rollers'line contact with raceway surfaces achieve a large load-bearing area despite the minimum dimensions. Therefore these bearings are widely used on the rotating parts of industrial robots, machine tools, precision rotary tables, measuring instruments and IC manufacturing machines.

Cross Roller Bearing Features:

High rigidity

Large load capacity

High rotation accuracy

Compactness

Easy to install and handle

PRECISION MOTION INDUSTRIES, INC.

製品の説明 :

In order to meet the market demand for high-speed and high-precision performance in the machinery industry, it is necessary to increase the motor speed and axial feed speed. Therefore, PMI developed a high-speed V-type ball screw to meet this stringent demand.

Feature:

► The Dm.n value has been highly improved.

► lower vibration and noise.

► The size of the nut is reduced by 10 ~ 20 %.

► Improved the smoothness and stability.

HAI JU TRADING CO., LTD.

製品の説明 :

High-strength connection and maximum sealing

Can you imagine high-quality products without screw connections?

Modern technology cannot do without them as detachable joints. In the industrial

sector, fluid technology, pneumatics and sealing technology are among the fields of

application. In those sectors, often additional functions such as sealing, insulation or

reuse of bolts are required – only to mention a few.

One classic example are adjusting screws on hydraulic components, steering boxes

and fuel injection pumps. For those applications, high-strength screw connections

with reusable bolts and sealing against leakage are essential. We provide the solution

that fulfils those high requirements: the SEAL LOCK® sealing nut. It prevents any

unwanted leaking of gaseous or liquid media. The SEAL LOCK® ring integrated on

the nut helps to achieve reliable sealing inside the thread without the use of

additional elements. It is reliable in two ways because it seals under the head and

inside the thread. Not to mention the easy installation.

The following figures show conventional solutions on the one hand and the

SEAL LOCK® sealing nut on the other hand.

ASMITH MANUFACTURING COMPANY

製品の説明 :

Dust-resistant, waterproof (IP66), resistance to heat and corrosion.

Patent: Pawl is fixed by 4 positioning points and the grooved shaft-bolt, easy for assembly and adjustment. Need only to slide the pawl through the shaft-groove to the correct position, more stable and accurate.

Left, right and top opening. The pawl moved forward and reversed vertically 3mm while the compression latch is opened and closed.

Used widely for door panel of general cabinet boxes.

Pawl can be easily positioned to accommodate the suitable compression.

In accordance with RoHS.

➤Material-body and lever: SUS304(stainless steel)-vibration ground and brushed finish in front.

➤Material-shaft, pawl and mounting bracket: SUS304(stainless steel).