展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

SUN FIRM MACHINERY IND. CO., LTD.

製品の説明 :

The latest Sun Firm CST-46160 is a horizontal CNC precision lathe offering high flexibility and processing efficiency. Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

CHIAH CHYUN MACHINERY CO., LTD.

製品の説明 :

■No matter what operation – turning, milling, drilling, tapping, cutting, side turning and back machining, the

CB series does it all in one operation.

■Sliding head without a guide bush design provide faster setups, lesser remnants, and more cost reduction.

■The CB series provide multiple tooling systems is suitable for versatile cutting applications. On the front side

tooling system, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools. Moreover, on the back milling

system, user can set 4 live tools. The maximum tool speed is 6000 rpm. User can install O.D. and I.D. tools

on the back milling system.

■The sub-spindle head moves on the precision roller type linear ways with extra-large span design for

outstanding stability and positioning accuracy.

SGCAM TECHNOLOGY CO., LTD.

製品の説明 :

主功能介紹:<br />

全中文畫面,易學、易懂、易用,為加工業最適合的加工軟體,操作軟體完全不用背指令。<br />

可由AutoCAD製圖畫出工件外形,再匯入DXF、IGS圖檔,轉換為CNC程式碼。<br />

不必畫3D圖形,一條輪廓線和一條路徑線一般2D圖即可輕鬆轉出車銑的加工程式。<br />

快速C軸填充式的輸入方式 ,很簡單的方式就能轉出C軸加工程式。<br />

參數式的C軸工法操作條件更改G碼自動跟著改變。<br />

製作程式時車銑工法可依加工順序任意作排序調整。<br />

3D實體切削模擬預覽,可避免干涉及過切事件發生。<br />

主軸和副主軸的獨動或同動會自動等待(指定機型) 。<br />

同一個程式中可同時指定不同的切削計算方式有走刀式、走心式、櫛式。<br />

車銑的刀具庫參數可依實際機台型號的刀具位置做個別指定。<br />

可在端面、圓弧面、橢圓面上做刻字。<br />

支援單筆劃字型刻字。<br />

系統支援:<br />

支援廠牌有Citizen 、Star、Miyano、Tsugami、洽群、縉錩、利高、精機、瀧澤、程泰、寶麗金…<br />

支援側銑側鑽等循環加工指令G87、G88、G184<br />

支援極座標G12.1 、G13.1、 G112 、G113<br />

支援圓筒補間G07.1、G107

LIS AUTOMATIC CONTROLLED CO., LTD.

製品の説明 :

The PJ-20S is a fixed volume medium pressure system without tank designed. Suitable for a general manufacturing environment, designed for Swiss lathes.

-modular PCB, easy to maintenance

-intuitive control panel, easy to operation

-3 sets of M code output

-compact size, saving space

CHIAH CHYUN MACHINERY CO., LTD.

製品の説明 :

SY2-42 Swiss-type CNC Lathe

■ SY2-42E has Ø42mm maximum bar feeding dia. and provide the option to go with or without a guide bush to achieve optimum machining condition.

■ Main spindle tool system can install 6 radial live tools, 3 axial live tools, 6 O.D. tools, 5 I.D. tools.

■ Sub Spindle tool system can install 8 ER-20 live tools, combines with the Y2 linear axis and C2 rotating axis to perform the more complex turning and milling process.

LIS AUTOMATIC CONTROLLED CO., LTD.

製品の説明 :

PJ-20V0 is a surprising design. In addition to the dead corners of the bar feeder, there are also many spaces that easy to ignore, used by customers to pile up the stuff and lose the value of use. The idea of PJ-20V0 revitalizes these spaces and is no longer limited to 2D imagination, also to evolve to the concept of 3D space. This system provides a powerful and compliant function system for users continuously. Using for continuous variable volume (pressure), saving the electricity cost and the time of the adjusted pressure. Suitable for the Swiss Lathes and gun drilling.

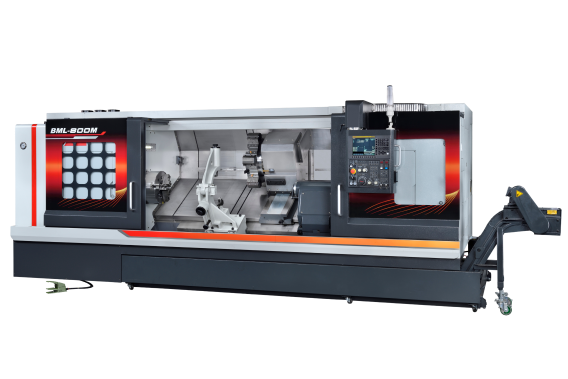

YIDA PRECISION MACHINERY CO., LTD.

製品の説明 :

The (B)ML-800 series is a highly customizable turning center with various options for spindle, gearbox, base, tailstock, turret and multiple selectable feed speeds. It can efficiently handle the most demanding machining requirements.

1. The modular structure design of the base has high strength and rigidity. It is molded as a single unit, effectively absorbing the vibrations generated by the machining and providing the stability and precision required for heavy cutting operations, without any distortion or deformation.

2. The optimal modular design spindle features high speed and power, and can be paired with a high-torque output gearbox design, offering a variety of processing options to meet different machining needs.

3. The robust toll turret design allows for quick and reliable tool changes, ensuring high efficiency and precision. It caters to the characteristics of various cutting processes, effectively enhancing machining capabilities.

3. The high-strength design of the transmission structure ensures precise positioning and greatly enhances machining efficiency and stability.

4. Ergonomically designed interface makes operation easy and maintenance convenient. Sheet metal design incorporates comprehensive safety considerations.

CAMPRO PRECISION MACHINERY CO., LTD.

製品の説明 :

Campro spares no effort to develop intelligent manufacturing; fully demonstrating its determination from Industry 3.0 to 4.0, Campro not only has successfully launched CAMPRO IIoT system in line with Industry 4.0 elements in 2016, but also developed its CAMPRO Smart FMS system in 2018. Through flexible manufacturing system, digital control and automated NC program and machine assignment that it can quickly react in case of changes and respond to market demand. In addition, CAMPRO also develops, CAMPRO TOOLING MANAGEMENT SYSTEM, a proprietary system combined with precision tooling/material cabinet to assist customers in managing and analyzing tooling/material usage, 24 hours to get tools or materials and early-warning or alert notifications. In some cases, the fact is increasing automation can improve worker safety and the flexible automation processing is sufficient enough to cope with complex manufacturing processes.

LEADWELL CNC MACHINES MFG., CORP.

製品の説明 :

Spindle nose A2-6 with 8” inch chuck for both spindles. The bar capacity of the main spindle is up to 52mm. Spindle uses high-power built-in motor with a maximum torque of 292Nm which for heavy cutting and surface milling operations. The capacity of the Y axis is ±50mm, which allow offset processing and increase the speed of milling.

Max. swing: 790mm

Max. turning diameter: 300mm

Max. turning length: 770mm

Bar capacity: 52mm

X1-axis travel: 235+15mm

X2-axis travel: 220+10mm

Z1-axis travel: 770mm

Z2-axis travel: 790mm

B-axis travel: 770mm

Y-axis travel: ±50mm

Spindle speed(Main/Sub): 4500rpm

Spindle nose(Main/Sub): A2-6

Spindle motor power(Main/Sub): 25kw

Number of tool stations: 16T

REN AN INFORMATION TECHNOLOGY CO., LTD.

製品の説明 :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.